The appearance of a diamond wire saw looks like a hard rope, especially for rubber ropes. At a glance, you won’t find the secrets inside the wire saw. Many people who don’t know the wire saw have an opinion on the inside of the wire saw. The structure is very curious. This article combines the structure of the wire saw to explain what is inside the wire saw?

The wire saw is composed of three parts. The functions of these three parts are the internal connection piece, the external connection piece, and the cutting tooth. Of course, some people divide the wire saw into four parts, which are the internal connection piece and the external connection piece. , Cutting parts, cutting material matrix (used to fix the cutting material).

When we see wire saw, the first thing we see is its external structural parts. There are mainly four types of external structural parts: the first type, rubber, which has stronger abrasion resistance and better elasticity, and is usually used in mining wire Cutting of hard materials such as saw and concrete. The second type is the spring wire saw. The spring has good elasticity, but the wear resistance is not strong, and once the force is too large, the spring is prone to deformation, so it is currently widely used in marble mining. The third is the spring + rubber combination mode. This combination can make full use of the spring's resilience and rubber's wear resistance. It has a good cutting effect for some granite mines with higher hardness. The fourth type is a plastic wire saw on the outside. This type of wire saw requires high rope weaving skills and is not very resistant to wear. However, the plastic fixed wire saw does not directly fix the inner wire rope, which will make the wire rope It can rotate freely, which reduces the possibility of bead movement, and does not reduce the occurrence of eccentric wear and displacement of the diamond wire saw bead.

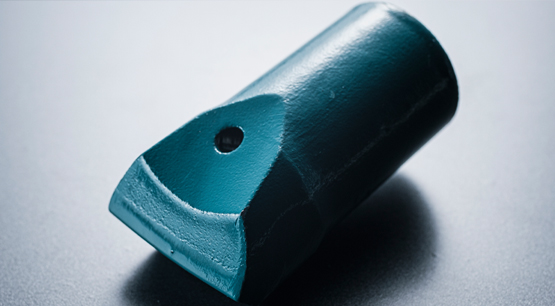

The protruding part is called a bead and consists of two parts. Like a car tire, the outer part is called the main cutting layer, and the inner part is called the base, which serves the purpose of fixing the cutting layer. The structure of the base body is a circular hollow cylindrical shape, and the material is high-grade alloy steel, which is hard and has strong tensile and impact resistance. The outer working layer is a layer of sintered blocks made of diamond and metal alloy powder. When cutting stone or reinforced concrete, the diamond in the sintered block quickly grinds the cutting object, and finally completes the cutting process. The thickness of the nodules can be adjusted. If cutting harder materials, the thickness can be slightly higher, which can appropriately increase the cutting life, but the thickness cannot be adjusted too high. If the thickness is too high, the stress surface will increase when cutting It will lead to a decrease in cutting efficiency, so the thickness of the working layer of the bead is generally maintained at 10.5-12.5mm.

The invisible part of the wire saw is the most important connection part of the entire wire saw-the wire rope. The wire rope is the basis of the entire wire saw connection. If there is no wire rope, the entire wire saw needs to be connected through countless joints, then the wire saw The advantages of cutting will not be reflected. So what is the particularity of the wire rope inside the wire saw? There are three main points:

First,The wire rope of a wire saw must be a steel wire with very strong tension, because in the process of cutting hard materials, there may be various hard cutting parts inside the cutting material, such as stone. Some parts are soft and some are hard. When we maintain the cutting speed of the wire saw, we suddenly encounter hard materials, and the wire saw needs to withstand greater friction. If the quality of the wire rope is poor, the rope break is inevitable.

Second, the wire rope adopts a more reasonable rope braiding method. For example, the current wire saw products of Lingxing diamond tools use 8-strand and 12-strand rope braiding methods, which can increase the tensile force of the wire rope by 20%-30%.

Third, a thicker wire rope will make the structure more stable. Although a thin wire rope has a certain tensile strength, it is not as good as a thick rope.

In general, the diamond wire saw is mainly the steel wire rope and the bead matrix, which is used to fix the core cutting part of the diamond wire saw, so that the bead is better used for cutting hard material objects.

The appearance of a diamond wire saw looks like a hard rope, especially for rubber ropes. At a glance, you won’t find the secrets inside the wire saw. Many people who don’t know the wire saw have an opinion on the inside of the wire saw. The structure is very curious. This article combines the structure of the wire saThe wire saw is composed of three parts. The functions of these three parts are the internal connection piece, the external connection piece, and the cutting tooth. Of course, some people divide the wire saw into four parts, which are the internal connection piece and the external connection piece. , Cutting parts, cutting material matrix (used to fix the cutting material).

When we see wire saw, the first thing we see is its external structural parts. There are mainly four types of external structural parts: the first type, rubber, which has stronger abrasion resistance and better elasticity, and is usually used in mining wire Cutting of hard materials such as saw and concrete. The second type is the spring wire saw. The spring has good elasticity, but the wear resistance is not strong, and once the force is too large, the spring is prone to deformation, so it is currently widely used in marble mining. The third is the spring + rubber combination mode. This combination can make full use of the spring's resilience and rubber's wear resistance. It has a good cutting effect for some granite mines with higher hardness. The fourth type is a plastic wire saw on the outside. This type of wire saw requires high rope weaving skills and is not very resistant to wear. However, the plastic fixed wire saw does not directly fix the inner wire rope, which will make the wire rope It can rotate freely, which reduces the possibility of bead movement, and does not reduce the occurrence of eccentric wear and displacement of the bead.

The protruding part is called a bead and consists of two parts. Like a car tire, the outer part is called the main cutting layer, and the inner part is called the base, which serves the purpose of fixing the cutting layer. The structure of the base body is a circular hollow cylindrical shape, and the material is high-grade alloy steel, which is hard and has strong tensile and impact resistance. The outer working layer is a layer of sintered blocks made of diamond and metal alloy powder. When cutting stone or reinforced concrete, the diamond in the sintered block quickly grinds the cutting object, and finally completes the cutting process. The thickness of the nodules can be adjusted. If cutting harder materials, the thickness can be slightly higher, which can appropriately increase the cutting life, but the thickness cannot be adjusted too high. If the thickness is too high, the stress surface will increase when cutting It will lead to a decrease in cutting efficiency, so the thickness of the working layer of the bead is generally maintained at 10.5-12.5mm.

The invisible part of the wire saw is the most important connection part of the entire wire saw-the wire rope. The wire rope is the basis of the entire wire saw connection. If there is no wire rope, the entire wire saw needs to be connected through countless joints, then the wire saw The advantages of cutting will not be reflected. So what is the particularity of the wire rope inside the wire saw? There are three main points:

1. The wire rope of a wire saw must be a steel wire with very strong tension, because in the process of cutting hard materials, there may be various hard cutting parts inside the cutting material, such as stone. Some parts are soft and some are hard. When we maintain the cutting speed of the wire saw, we suddenly encounter hard materials, and the wire saw needs to withstand greater friction. If the quality of the wire rope is poor, the rope break is inevitable.

Second, the wire rope adopts a more reasonable rope braiding method. For example, the current wire saw products of Lingxing diamond tools use 8-strand and 12-strand rope braiding methods, which can increase the tensile force of the wire rope by 20%-30%.

Third, a thicker wire rope will make the structure more stable. Although a thin wire rope has a certain tensile strength, it is not as good as a thick rope.

In general, the diamond wire saw is mainly the steel wire rope and the bead matrix, which is used to fix the core cutting part of the diamond wire saw, so that the bead is better used for cutting hard material objects.