In the early molding process of diamond segments, people used the simplest heating and pressurizing way to molded the segments,then complete the sintering process, but this processing method has great damage to the molded steel body material. In previous the steel body is deformed after one set of molds are only used less than a few times, so people try to seek more scientific sintering methods to make sure the mold can be sintered multiple times, thereby reducing the sintering cost and further reducing the price of the segments. And after many tests, it was found that this brutal heating and pressurizing method is not conducive to better shaping of the segments. After several years of research and development, Linxing Diamond Tools finally found a very suitable sintering method.

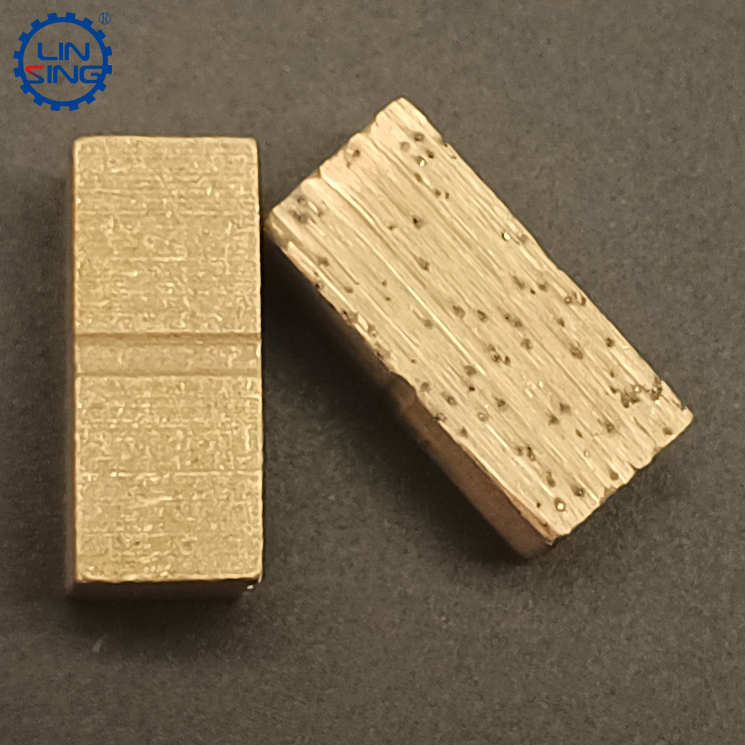

First pre-pressing (also called cold pressing), the pre-pressing process is in the early stage of sintering the diamond segments, put the working layer and non-working layer of the segments into the mold and put it into the manual or automatic cold press. Perform cold pressing at a certain pressure. Generally this pressure is determined by the material of the segments. If there are more paraffin and metals with low melting points, the pressure should be higher, otherwise the pressure can be lower, generally maintained at a pressure of 1000-2000kg/cm2. Normally The thickness of the good segments blank is basically up to the size, and the width needs a little more height, here is the margin for sintering.

For calcining, put the cold-pressed segments into a graphite abrasive tool, and then send them to a hot press machine. The hot press machine must be energized and heated first till reaches the sintering temperature, and the segments calcining process continues until the mold is cooled to room temperature, and the duration is very long.This process is called the early stage of the calcining process.

For Pressing. when the mold temperature reaches the sintering temperature and keeps it for a period of time, pressure can be started. Through high pressure, the working layer and the non-working layer of the segments can be combined well. When the segments is pressed to a certain size, then it starts to reduce pressure and temperature.

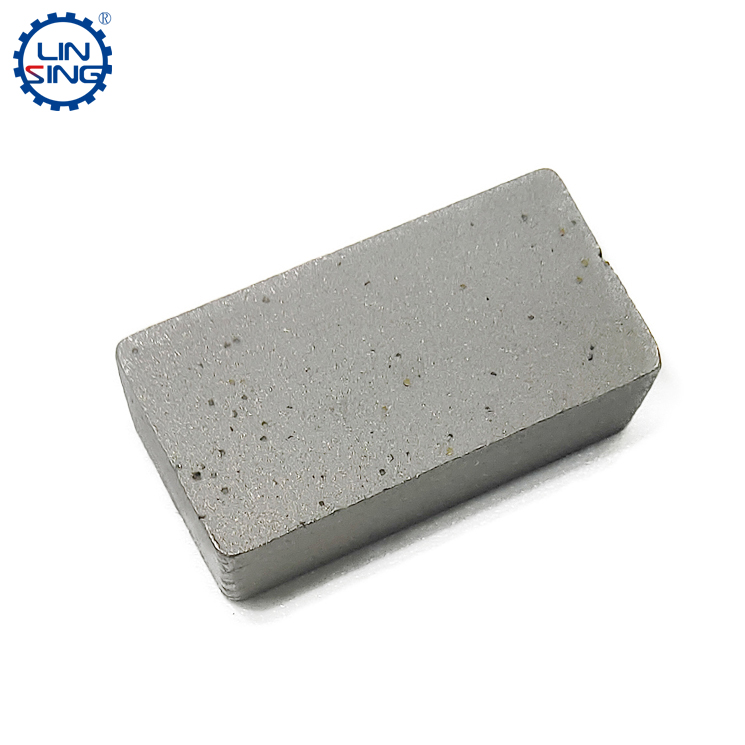

Finally, the mold is placed on the steel plate and cooled to room temperature. Then the entire sintering process is completed. At this time, the diamond segments can be taken out for the quality inspection.

Sintering process of Linxing diamond segments

Publish date:2022-07-05 17:38:23 Article From:Linsing Diamond Tools Clicks:

Diamond Wire Saw For Marble Mining&Quarrying

Diamond Wire Saw Beads

Diamond Wire Saw For Granite Quarrying

Diamond Core Drill Bit

Taper Chisel Bit

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- Cold - pressing porcess of diamond segments

- Why does the diamond segment not cut the stone? Over-carbonization is one of the reasons

- Hot pressing sintering technology of diamond segment

- What should do if the segment is moved grinding during the cutting process?