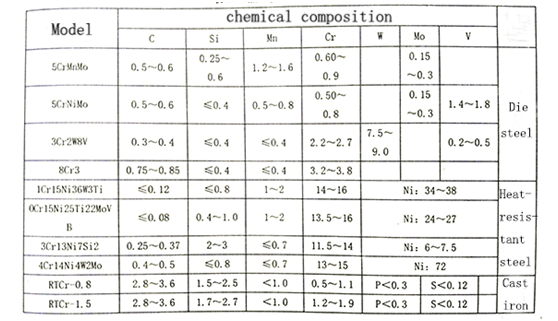

Graphite moldsurface is generally made of high-strength steel and cast iron materials, whichare convenient for applying pressure and heating.The properties of common moldmetal materials in China are as follows:

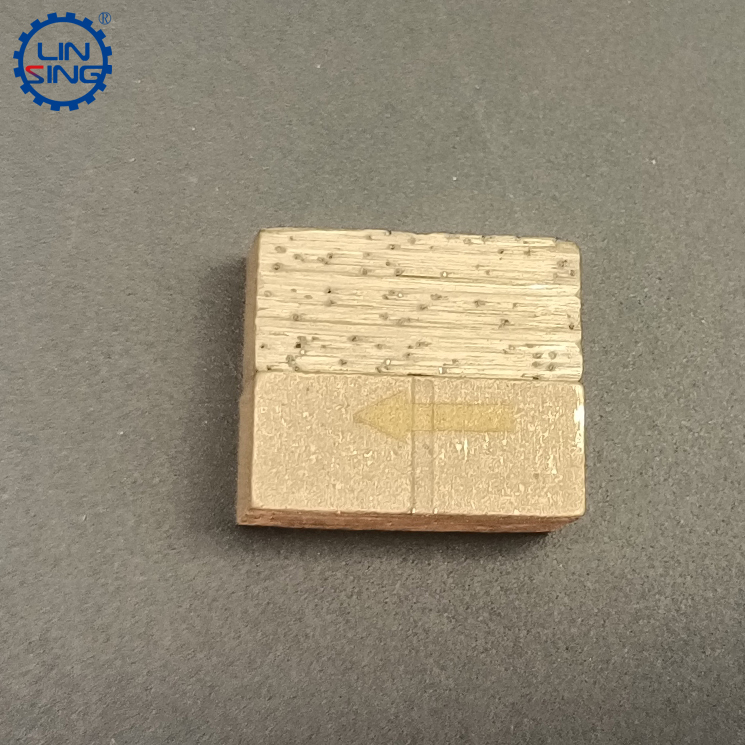

In the internal material selection of the mold, graphite materials are generallyused, mainly reason is graphite has good electrical conductivity, and itsthermal conductivity is also better than general non-metallic materials andsome metal materials, especially in compression performance, which can be saidvery excellent. The practical testing indicates that the compression strengthof the compacted graphite molds can be reach 45MPa. Therefore, graphite asheating molding materials and high-pressure molding materials has become verycommon.

In the forming process of diamond segments, the graphite with lowercost and the economical availability(can be usedmultiple times)arealso the main reasons of used as the material for hot pressing forming processof diamond segments.Inaddition to the above advantages, graphite also has a small thermal expansioncoefficient, it can withstand rapid changes in temperature without cracking,and the reaction effect of thermal expansion and contraction is low, so that itcan maximum guarantee the material under the high temperatures still can bekeep uniformity shape with the segments; and the matrix material of the diamondsegment is mostly metal substances and high-temperature liquid substances ofparts of the bond, the thermal expansion coefficient of these materials is muchlarger than graphite. The advantage is that in the later period of demouldingprocess, the formed segments will not fall off due to the severe shrinkage ofthe mold; in addition, during the hot pressing process of the graphite mold,the graphite surface will react with oxygen to generate CO or CO2 gas, which canprotect the diamond and the matrix material from oxidation, and maximumensuring the beauty of the finished product.

Of course, Even though the graphite mold is good, but they also have certainshortcomings. The main reason is that the porosity of graphite is relativelylarge, during the hot sintering process, the liquid metal (low melting pointcomponent of melted) in the bonding is easily squeezed into the voids of thegraphite pores, then the mold becomes brittle and easy to crack. Moreover, duringthe unloading process, the mold wall will be roughened and deformed, which willcause the segments quality become decline and damage the outlook of thesegments, so that mold needs to be replaced.

Therefore, you must pay attention when choosinggraphite mold for diamond segments processing. First, choose graphite with thehigher strength, the higher the better, and it is best to exceed 45MPa. Second,choose graphite with a lower porosity, the lower the better, which can maximizethe number of molds used, thereby reducing costs.