Block cutting marble segment writing: length * width * height. For example, the size of the commonly used 2-meter saw blade segment is written as: 24x10.5x8, in mm, where 24 refers to the length of the blade segment (along the saw blade base saw tooth, the upper and lower lengths are the same as the front and rear sides of the saw blade). body is in parallel state); 10.5 refers to the width of the cutter segment (the left and right ends of the saw blade serrated part, parallel to the measurement line of the thickness of the substrate); 8 refers to the height of the cutter segment, which is the segment welded on the saw blade,the distance between the bottom of the segment and the farthest end of the entire saw blade. This height is divided into various heights due to the different requirements of each customer. In order to better distinguish these cutter segments, the writing method can be expanded to 24x10.5x8 (10, 12, 13, 15), of which the rear part is other cutter segment products of different heights.

So how to write the marble edge cutting saw blade? If it is an arc-shaped cutter segment, the size is no different from the above block cutting cutter segment, but in particular there is a fan-shaped cutter segment, the cutter segment and the center of the saw blade form a fan shape, so that the saw blade cutter segment is written has been changed. Let's take an example. For example, the size of the blade segment of a fan-shaped marble saw blade with a diameter of 400mm is written like this: 42/40x3.6x8 (10,12,15), which means that the top of the blade is curved, the length is 42mm, while the length of the welded part is 40mm.

There are also gang saw segments used for cutting marble. The shape of the gang saw segments is very special. Generally speaking, the common gang saw segments are wide in width and narrow in the bottom. Such a gang saw has a 3mm row spacing. The segment of the body is written as: 20x5.0/4.5x8(10), where 20 is the length of the gang saw blade, 5.0 is the thickness of the top of the cutting tooth, and 4.5 is the thickness of the blade at the bottom of the welding, 8(10) The writing method shows the optional height of the row distance cutter segment, 8mm or 10mm can be selected according to customer requirements.

The relatively new row pitch cutter segment also has a trapezoidal shape in the length direction. The length of the bottom of such a cutter segment can reach 24mm, and the writing method has also changed: 20/24x5.0/4.5x8(10)

The writing method of the granite cutting segment is roughly the same as the writing method of the row distance cutting segment. Since chip removal and cooling are very important in the granite cutting process, when designing the granite cutting segment, it is necessary to reserve enough width. For example, a granite cutting segment:

24x7.4/6.6x15(13,20)

where 24 is the length of the segment, 7.4 is the width of the top of the segment, 6.6 is the width of the welding surface of the segment, and 15 is the default Height, 13 and 20 are the more common segment heights.

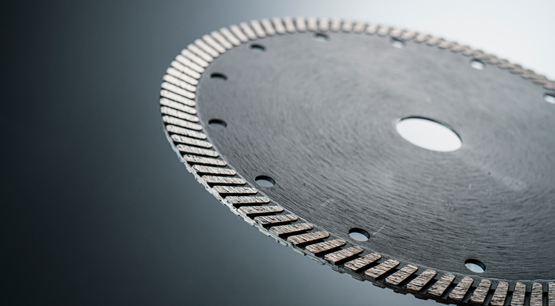

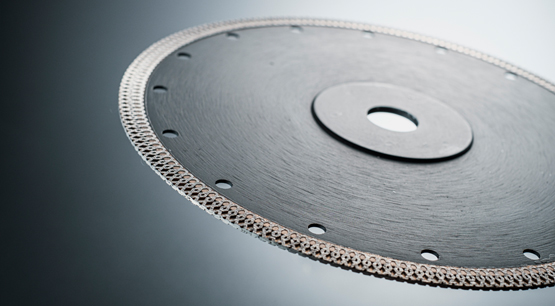

The dimensions of other saw blades are based on this writing method, except for some special saw blades, such as continuous saw blades, turbine blades, which have different writing methods, because the blades of these saw blades are all continuous styles. The length is not reflected, so only the width and height need to be reflected, such as 1.8x10, which represents the thickness of the blade segment of 1.8, and the height of the blade segment of 10.

Summarize the relevant writing methods of the size of the diamond saw blade segment. The length is placed at the front, and the length is generally divided into two different lengths of the upper and lower lengths of the cutter segment. The upper size is written in the front, the lower size is written in the back, and the middle is written with "/ "Separated, and the width is behind the length data, the width data is divided into two data: upper width and lower width, the writing method and length are consistent, and finally the tool segment height data, generally write the most commonly used in the front, the less commonly used ones are written in the "()" at the back, and the values are separated by ",". It is worth noting that "*" or "x" is used in the middle of the length, width and height to divide the data.

43(42)/40(39,38)*4.2*10(8,13)

The most special thing is that when there are more choices for the size of some cutter segments, the writing method changes more. Can you understand the size of the cutter segment below?

43(42)/40(39,38)*4.2*10(8,13)