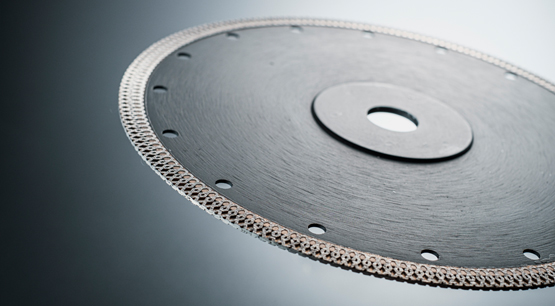

Diamond saw blade in the process of cutting stone, Due to a variety of reason diamond saw blade will lose it’s sharpness. What is the specific reason lead this happening? Let’s have a look:

A: Stone hardness is too high, saw blade in the process of cutting stone diamond will be come flat very fast. The polished diamond connot cut the stone continuously, so the saw blade can not process stone.

B: The stone hardness is too soft, This situation is usually happening when cutting marble. Especially cutting limestone, due to the low abrasiveness of these stone and the bond of the segment of diamond saw blade is relatively wear-resistant. It’s consume lowly and in this situation diamond will be smoothed and when the new diamond can not be opened, the saw blade will lost it’s sharpness then it become to a dull saw blade.

C: Diamond of saw blade is large but can not open.It’s common in marble saw blade, In order to increase the life of the segment, some manufacturers use larger particles of diamond when designing the segment formula. However, these diamonds are not easy to emerge during the cutting process. During the cutting process, due to the soft marble material, the impact and crushing of the diamond cannot be completed, so there is a situation where the segment does not cut the stone.

D: The cold water is too large, In the process of stone cutting, adding appropriate cooling water can help the segment to cool down quickly, but if the water amount is not well controlled, the cutter head will slip during the cutting process. Simply put is the friction between the cutter head and the stone is reduced, and the cutting ability is naturally reduced. If this continues for a long time, the diamond consumption of the segment will be reduced, and the exposed diamond will be slowly rounded, and naturally the saw blade will become blunt.

E: That is, the quality of the diamond saw blade head itself is a problem, such as problems in the sintering process, formula, mixing, etc., or the blade uses poor powder materials and diamond powder, resulting in unstable products. It is also possible that in the production process, there is a problem with the ratio of the middle and edge materials, and the consumption of the middle layer is far lower than the consumption of the edge layer material, and such a cutter head will also show the appearance of a dull saw blade.

So is there any solution to the dull saw blade? Here are a few common ways to improve the sharpness of a saw blade.

1: If the saw blade becomes dull due to the hardness of the stone, the main solutions are as follows: By mixing hard and soft stones, the diamond is exposed to a normal cutting range; after cutting for a period of practice, according to the actual situation of the segment, cut some refractory bricks and let the segment re-open. This type of re-sharpening is extremely common. Another way is to select a segment with a larger contrast according to such serrations for mixed welding, For example, in the process of cutting, the segment carcass is too hard and becomes blunt, so it is necessary to use some segments with softer segment carcass for tooth spacing welding which will gradually improve this problem. There is also a relatively simple way to cut hard stones, increase the current, reduce the speed of the knife and the speed of the knife, and the opposite for cutting soft stones.

2: If it is the problem of diamond particle size, the diamond with large particles needs to increase the current, increase the linear speed, and increase the impact crushing force, so as to ensure that the diamond is continuously broken.

3: The problem of cooling water is also easy to solve, reducing the flow of cooling water, especially in the process of granite cutting, the large amount of water will definitely cause the saw blade to become dull.

4: If it is a problem with the quality of the cutter head, establish a larger diamond tool manufacturer, and deploy a diamond cutter head formula suitable for your own manufacturer, so that the saw blade cutting process is more in line with your expectations.