Before introducing how to distinguish diamond saw blades, we must first understand the types of diamond saw blades. Diamond saw blades can be divided into large saw blades for block cutting, saw blades for plate cutting and small cutting blades for hand-held machinery according to their size. If divided according to the process, it can be divided into cold-pressed sintered disc, vacuum brazed disc, electroplated disc, laser disc, high-frequency welded disc, PCD saw blade, etc. It can also be divided into saw blades for cutting granite, cutting marble, cutting tiles, cutting concrete, cutting masonry structures, cutting asphalt, etc.

Knowing this, how to distinguish diamond saw blades?

Different sizes, different saw blade sizes, different uses of diamonds. Generally speaking, saw blades with a diameter of more than 900mm are mostly used for cutting blocks. Except for a few saw blades with a diameter of about 1200mm, which are used to cut concrete, other larger size saw blades are used to cut stone. The diamond saw blade products with a size of 300-850mm are widely used, and most of them are used for the cutting of concrete, asphalt, stone, ceramics, and refractory materials. The saw blades with a diameter of less than 300mm are mostly cold-pressed saw blades, which can be used to cut almost all hard materials, but the efficiency is low.

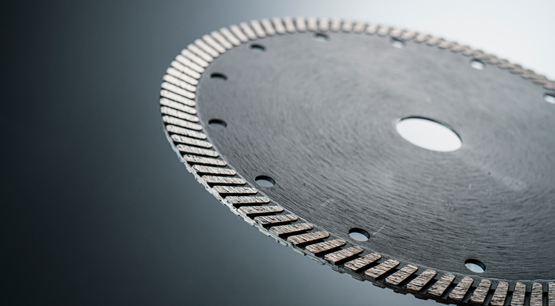

Differences in craftsmanship: Most of the cold-pressed sintered blades are small-sized saw blades. The most prominent feature is the sintered segment that can be seen. The size of the vacuum brazing blade is 105-300mm, and the larger size is not made because the blank blade material cannot be reused and the cost is high. The brazing blade is available in two colors, silver or gold, with strong concave and convex. The electroplating blade is similar to the brazing blade, but the diamond layer powder is more uniform and the color is silver white. Compared with the brazed blade, the gloss of the electroplated blade is lower. Laser blade is also a common saw blade, the biggest feature is the way of welding. The most obvious point is that the gap at the welding place is large, which is not easy to handle in the later stage, and it is more ugly. The high-frequency welding blade is the most common saw blade. It is welded by the welding rod, and the imprint left by the welding rod can be clearly seen, and the welding seam is small. PCD saw blade, the biggest feature of this saw blade is the cutting blade with PDC at the tip of the saw blade, which can cut hard materials.

Sawtooth Distinction: The teeth of the diamond saw blade are very particular, and the following aspects need to be understood: U-shaped slot saw blade, this type of saw blade has a good cutting ability. In terms of cutting continuity, it depends on the width of the U-shaped slot. The U-shaped slot has a wide range of uses and a variety of uses. Key-slot saw blade, this type of saw blade has good sharpness, but will be weaker than U-shaped slot saw blade in terms of continuity. Saw blades with narrow gaps, such as fish hook blades, linear slot saw blades, which are easy to cut brittle materials. Continuous blades are mainly used for materials with higher requirements for cutting effect and higher requirements for edge chipping.

Distinction in use: Most of the distinctions of diamond saw blades in terms of use are reflected in the body of the saw blade. For example, saw blades for cutting marble, saw blades for cutting granite, saw blades for cutting reinforced concrete, saw blades for cutting asphalt, road blades, refractory brick cutting blades, etc.

The difference between dry and wet cuts: Dry cutting saw blades generally have some holes in the blade body for better heat dissipation, while saw blades generally used for water cutting are relatively flat and have no hole design.

All in all, the simple distinction of diamond saw blades is a relatively basic knowledge. People can better select the saw blade through the introduction of the blade body, the technology of the saw blade, the appearance of the sawtooth part, the porosity of the saw blade body, and the thickness of the blade body.

How To distinguish Diamond Saw Blades From Appearance

Publish date:2022-07-04 10:31:37 Article From:Linxing Diamond Tools Clicks:

Brazed diamond cutting blade is a very special diamond tool This saw blade uses vacuum brazing to fix the diamond on the saw blade substrate The entire saw blade has a simple structure and less sintering and welding processes, the stability is higher This article mainly introduces the advantages and disadvantages of brazed diamond cutting discs

07/04

2022

Why Are Super Large Diameter Diamond Saw Blades Not Used For Block Cutting?

Diamond saw blades have great application differences according to the change in size For example, the size of the saw blade for cutting blocks is mainly concentrated in 900-3500mm Why aren t super large diameter saw blades used for block cutting? What s the difficulty? Can it be solved? These are the questions to be discussed in this article

07/04

2022