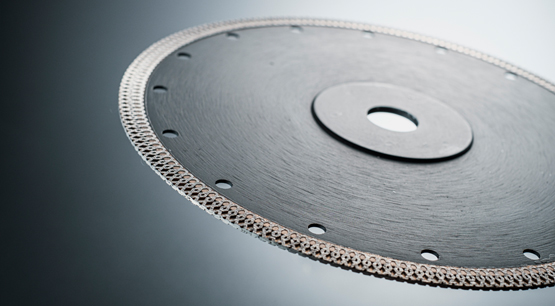

Brazed diamond cutting saw blade is a kind of diamond sawing tool that uses vacuum brazing to fix diamond on the base of the saw blade. At present, it is more and more widely used in sawing engineering. In the future, it is believed that with the gradual development of sawing tools, brazed diamond saw blades will have more development prospects. The main reason is that brazed saw blades have the following seven advantages.

1: The production of vacuum brazed cutting disc is very fast. Although large-scale equipment such as a brazing furnace should be invested in the early stage of vacuum brazing, once the equipment is put into use normally, the whole brazing process is very fast, and the simplification of the production process can reduce the production cost of brazing saw blades, while the standard products of intelligent mechanization will gradually replace the cumbersome ordinary diamond saw blades due to the increase of labor costs and become the mainstream products of industrial cutting in the future.

2: Energy saving and emission reduction. The vacuum brazing cutting blade is used to fix the diamond by brazing in a vacuum environment. Since the whole process is carried out in a vacuum, especially vacuum brazing is a relatively environmentally friendly production method, the whole vacuum brazing process will not generate waste gas and water, it can achieve the green production.

3: The cutting is fast. The diamonds of the vacuum brazed diamond cutting blade are distributed on the surface of the saw blade, all the diamond is exposed, and the vacuum brazed surface presents an uneven effect due to the brazing process. During the cutting process, the same cutting line speed, the more exposed the diamond, the more cutting edge, the better the cutting effect. In addition, the uneven cutting surface will reduce the area of the saw blade involved in cutting. Under the same force, the cutting strength of the saw blade will naturally increase, so it is obvious that the vacuum brazed saw blade is much faster than the traditional diamond saw blade. Because of this feature, fire rescue will be equipped with this type of saw blade to achieve the purpose of fast cutting.

4: Can be dry cut. Vacuum brazed diamond saw blades are produced by vacuum brazing process. Unlike traditional saw blades, they do not require welding rods or solders for welding, and the temperature of welding rods and solders is relatively low. In order to achieve a good cutting effect , Ordinary saw blades generally need to be cut in a water environment, and brazed diamond saw blades can be used for dry cutting because they are not affected by welding. Of course, in order to avoid the occurrence of excessive diamond carbonization, it is also necessary to ensure that the single dry cutting time should not be too long.

5: The sharpness is extremely high. Brazed diamond saw blades come in a variety of styles, such as serrated saw blades, this particular saw blade can be extremely sharp. Since this kind of saw blade is not suitable for cutting hard materials, it is not widely used at present.

6: Appearance processing is simple and beautiful. Compared with traditional saw blades, vacuum brazed diamond saw blades have the characteristics of beautiful appearance and easy post-processing. Compared with traditional saw blades that require silk screen printing and laser printing, they are much simpler.

7: Wide application. Vacuum brazed saw blades can cut many kinds of hard materials, almost through cutting, which is better than ordinary diamond saw blades, because most ordinary saw blades cannot cut a variety of materials, especially granite saw blades, it cannot be used to cut marble, otherwise there will be a situation where the edge cannot be cut.

Of course, brazed saw blades also have disadvantages, such as the price is relatively expensive, cannot be reused, and the service life of the saw blade is relatively short. However, with the continuous development of brazing technology and diamond technology, it is believed that the price should be continuously optimized, and the service life will be gradually increased, thereby reducing the cost of use and achieving the maximum cutting benefit.

Advantages And Disadvantages Of Brazed Diamond Cutting Saw Blades

Publish date:2022-07-04 17:24:38 Article From:Linxing Diamond Tools Clicks:

Brazed diamond cutting blade is a very special diamond tool This saw blade uses vacuum brazing to fix the diamond on the saw blade substrate The entire saw blade has a simple structure and less sintering and welding processes, the stability is higher This article mainly introduces the advantages and disadvantages of brazed diamond cutting discs

07/04

2022

Why Are Super Large Diameter Diamond Saw Blades Not Used For Block Cutting?

Diamond saw blades have great application differences according to the change in size For example, the size of the saw blade for cutting blocks is mainly concentrated in 900-3500mm Why aren t super large diameter saw blades used for block cutting? What s the difficulty? Can it be solved? These are the questions to be discussed in this article

07/04

2022