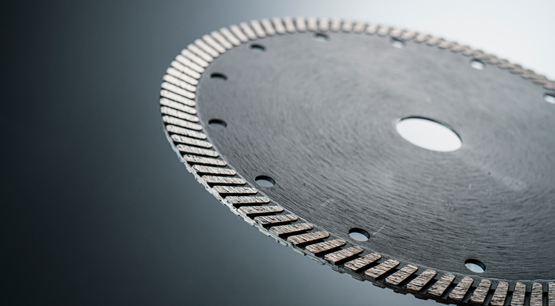

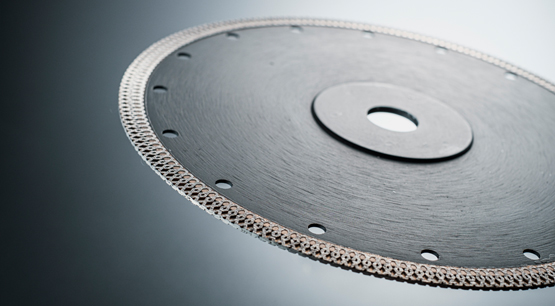

The dynamic working stability of the circular saw blade refers to the property of the diamond circular saw blade to maintain its inherent shape and stiffness when sawing the stone. In other words, in the process of processing stone, the working stability of the circular saw blade is worse than that of the gang saw and the multi wire saw. This is mainly because the ratio of the diameter to the thickness of the saw blade is very large, and only the clamping disc is clamped on the spindle for high-speed rotation and cannot be tensioned. The diamond segment part only relies on the bonding force of the metal material of the saw body to maintain a certain rigidity. When the saw blade rotates at high speed, under the action of centrifugal force, the cutting segment of the saw body begins to relax. In addition, in the process of sawing stone, especially the dry cutting saw blade, the temperature of the diamond segment part increases sharply, and the volume expands. The saw blade is limited by the material, and the heat resistance is required to be high, and it is impossible to expand and contract at will. In this way, there will be a special situation where the saw blade has a deformed cutting state with large external deformation and small internal deformation. In the long-term cutting process, the saw blade will gradually swim to both sides, in a "snake" state, and eventually the cutting surface will be uneven.

Let's analyze several factors that affect the working stability of diamond circular saw blades and improvement measures.

一.The increase in centrifugal force will directly lead to the unstable operation of the diamond circular saw blade. It is mainly reflected in the increase in the drilling speed of the saw blade, the increase in the amplitude of end jump and radial jump, and the inevitable jump of the segment during the cutting process, resulting in an unbalanced cutting state. Therefore, if the saw blade jumps obviously during the cutting process, reducing the linear speed can reduce the reduction of the working stability of the saw blade.

二.Influence of cutting heat and displacement due to temperature gradient. When the diamond saw blade cuts the stone, the temperature of the diamond segment is higher than the temperature of the substrate, and there is a temperature field with high outer and inner low on the saw blade. According to the research of scientists, a saw blade with a thickness of 1 mm will deform in a wavy shape when the temperature difference of the saw blade along the radial direction reaches 9 ℃. Saw blades of other thicknesses will also deform significantly according to the increase in cutting temperature. In the process of cutting stone, it is better to cut with water. If it is dry, it must be stopped for a period of time to rest, and the segment should be cooled before cutting.

三.Influence of radial jump and end vibration on machining quality during circular saw cutting. In the process of cutting stone with diamond circular saw blade, due to the large number of segments, the jump of each segment is inconsistent. So a small radial jump will have a greater impact on the cutting thickness of the stone. In terms of end jump, it mainly affects the roughness of the cutting surface. The solution is more complicated. In addition to the process of redesigning the substrate, taking into account these details, improving the rigidity and toughness of the saw blade substrate is the only solution.

四.Critical speed. The critical speed is mainly manifested in the moment when the speed of the saw blade changes from rest to moving and the moment when the saw blade is overloaded. When the stationary saw blade begins to rotate, critical speed begins to change, and at this moment, the cutting of the saw blade becomes unstable. So under normal circumstances, after starting the machine, be sure to let the saw blade run idly, keep the speed, and then cut. For a saw blade with a critical value, the load cutting situation will definitely lead to a large swing of the saw blade, so appropriately reducing the cutting speed can quickly solve this problem.

五.Matrix stress. The initial stress in the diamond saw blade includes residual stress and tensile stress, which is almost unavoidable. Because it exists in the manufacturing process of the saw blade, this stress will cause some unnatural fluctuations in the saw blade, but the fluctuation of each saw blade is not consistent. So how to reduce the saw blade stress is the only way to solve this problem. There are many ways to reduce stress on circular saw blades, such as thermal correction. 1. Cold calibration method; This method means that only local pressure is applied to the base of the saw blade, but no heating. 2. Hot calibration method; locally heat the saw blade substrate, but do not pressurize it; 3. Comprehensive method; partially pressurize and partially heat the base of the saw blade.

All in all, there are many ways to improve the stability of the circular saw blade. According to the different conditions of the saw blade, different correction methods can be selected to solve the problem.