Generally, when we use stone saw blades, we often encounter various problems. Common problems include burning chips, sparks, jumping knives, falling segments, not sharpness, etc. Let’s talk about them carefully!

Common cutting problems of diamond saw blades in the process of cutting stone:

1. Burnt while cutting of the saw blade; The specific performance is that the diamond segment part of the diamond saw blade turns red or even black, and the temperature rises rapidly and cannot be lowered. The main reasons for this may be the following:

1). The matrix of the stone saw blade is too hard, the diamond falls off improperly or the diamond blade height is not enough;

2) . The linear speed is too low during the stone cutting process, and the cutting depth is too high.

3). The rigidity of the saw blade body is insufficient, and there is a bending situation.

2. sparking when cutting; Fire is also called sparking, mainly because the saw blade sparks during the cutting process. This situation will cause obvious black cutting marks on the plate in the most serious case. The fire phenomenon is mainly caused by the following reasons:

1). This situation occurs when the diamond is improperly distributed, because the rare part of the diamond cannot cut the stone during the cutting process.

2). The metal bond is too hard and too soft will also lead to this situation, too hard metal bond will cause the diamond to consume too slow, too soft metal bond will cause the diamond to consume too fast.

3). Abnormal diamond particle size and concentration can also lead to this problem. In general, sparking when cutting is mainly caused by the violent cutting process between the matrix and the stone, which is mainly caused by the problem of the diamond segment matrix and the diamond.

3. Jumping when cutting; The specific performance of the jumping of the saw blade is that during the cutting process of the stone, the cutting is unstable, and the blade jumps, oscillates left and right, and jumps up and down. The main reason is that improper detachment of the diamond in the saw blade segment will cause the saw blade to jump, and the holding force of the metal bond also determines the amplitude of the knife. In addition, the sudden change of the stone structure will also cause the saw blade to jump.

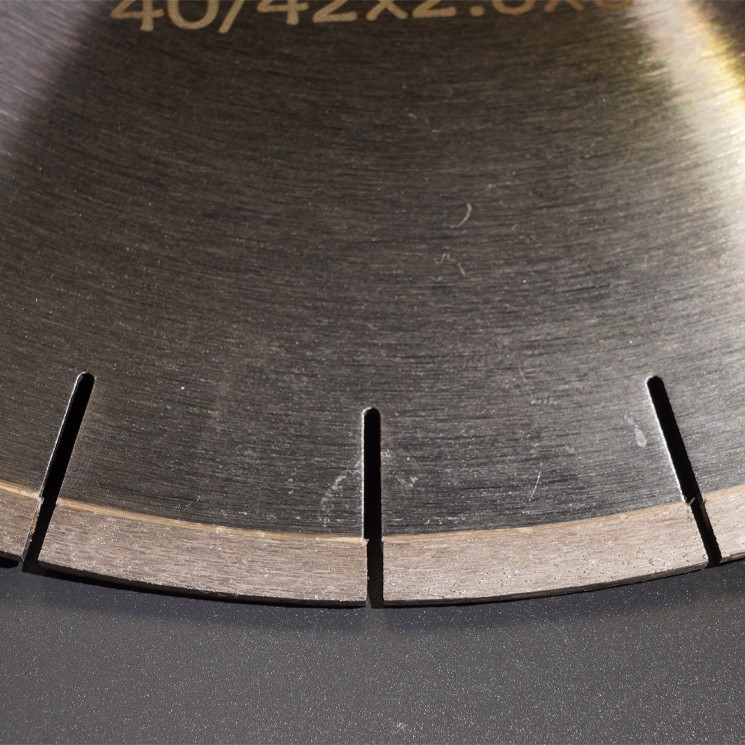

4. Falling off the diamond segment when cutting; It is very common to lose the diamond segment, and there are many reasons. The common reasons are as follows:

1). Welding problem, when welding the diamond segment, it is not welded well.

2). The stone is too hard and the saw blade is not sharp enough.

3). The diamond segment bond is too soft or too hard.

4). The cutting depth is too high.

5). The rigidity of the saw blade blank is insufficient.

6). The cooling water flow is too small, causing the diamond segment to overheat.

7). The diamond concentration is too low or evenly distributed.

8). During the sintering process, the material is not mixed uniformly.

5.The diamond saw blade not sharp when cutting; It is mainly manifested in the process of diamond saw blade sawing stone, the sharpness of the diamond segment is reduced or the cutting speed is slow, the cutting speed is slow. Once the cutting speed is set high, the motor current will be too high.

The saw blade is not sharp, mainly in the production process of the diamond segment of the saw blade. During the heating and sintering process. There are some gradient differences in the upper and lower temperatures in the mold, the powder activity state and the difference in the distribution of low melting point materials. The sintered structure and mechanical changes in performance, this is a micro aspect. The accumulation of heat during the cutting process weakens the mechanical properties of the welded blank of the stone saw blade. The strength of the matrix tissue is weakened by the vibration and impact force transmitted by the diamond, resulting in the reduction of the matrix's holding force on the diamond. In other words, cutting fatigue occurs during sawing. In addition, there are many reasons for the unsharpness of the saw blade, such as insufficient diamond concentration in the diamond segment, unreasonable diamond particle size ratio, insufficient holding force of the matrix to the diamond segment, etc., all of which will cause the diamond saw blade to have a slow cutting speed.

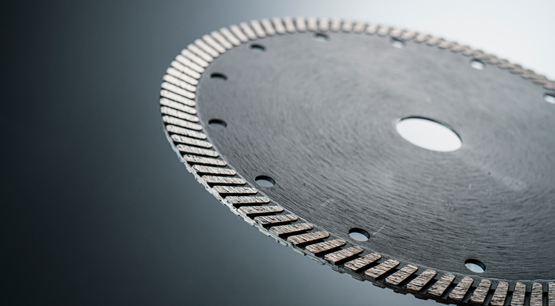

The most commonly used specifications of stone saw blades are saw blades with a diameter of 300MM, 350MM and 400MM. LINSING diamond saw blades have the characteristics of high sharpness, high cutting efficiency, stable cutting, small cutting gap and long service life. Welcome customers to come to consult.