The diamond saw blade first needs to determine the cutting function of the cutting product. For example, what material is to be cut. After the cutting material is determined, the type of cutting blade can also be determined. After determining the type of saw blade, the next step is to select the material, diameter, tooth number, etc. of the stone saw blade according to the workpiece to be sawed, or customize the appropriate saw blade to ensure a good sawing effect.

1.The choice of stone saw blade material

Diamond saw blades first need to know the specific cutting material. For example, saw blades for cutting aluminum generally use carbide, while saw blades for cutting hard stone are mostly high-speed steel or high-manganese steel. Most of the cutting ceramics use alloy steel. In order to cut high-precision materials, it is more advantageous to use carbide alloy steel as a saw blade.

The size and material of the cutting discs for cutting stone are also quite different. For example, for saw blades smaller than 230mm, it is enough to use a cemented carbide base. However, for 250-850mm saw blades, most of them are manganese steel or high-speed steel. This type of steel has higher rigidity, which ensures the quality of cutting and also takes into account high safety.

The larger the saw blade, the higher the quality of the base steel required. Especially for large saw blades over 2000mm, good steel produces minimal cutting vibration during the cutting process, and it is also relatively convenient in the later maintenance and maintenance process. The price of a good saw blade base will also be high, and it is very important to choose a suitable saw blade base.

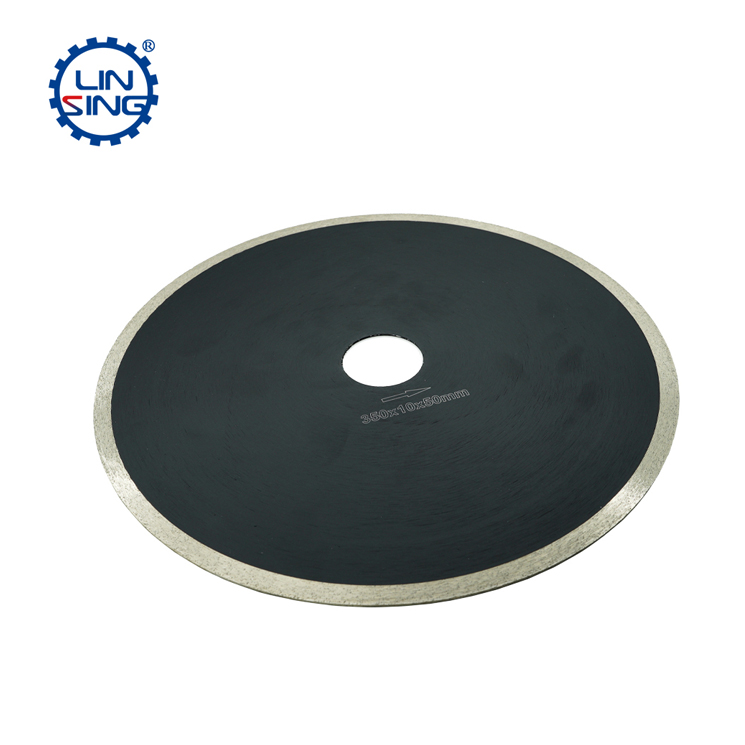

2.The choice of stone saw blade diameter

In the case of the same thickness, the size of the blade diameter determines the output of cutting, the smaller the diameter, the lower the output, and the larger the diameter, the higher the output. The outer diameter of the saw blade is selected according to different circular saw models and the saw blade with the same diameter is used. In addition to output, the stability of cutting should also be considered. The thicker the saw blade, the higher the cutting stability and the larger the cutting gap. The thin saw blade, the cutting stability is weak, the cutting gap will also be reduced.

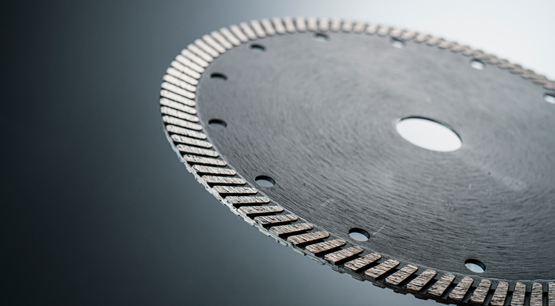

3 Selection of the number of teeth

Generally speaking, the more the number of saw blades, the more cutting edges can be cut in unit time, and the better the cutting performance. The price of saw blades is high. If the segments are too dense, the amount of chips between the diamond segment will become smaller, which will easily cause the saw blade cutting the stone to heat up. In addition, there are too many segments. If the feed rate is not matched properly, the cutting amount of each segment is very small, which will increase the friction between the cutting edge and the workpiece, and affect the service life of the cutting edge.

Usually, the distance between the segments is 15-25mm, and a reasonable number of teeth should be selected according to the material to be sawed. Normally, customers who have requirements on the cutting effect choose multiple segments to control the cutting quality, but if there is no requirement for the cutting quality, increasing the distance between the segments can appropriately improve the cutting ability of the saw blade.

4. Choice of aperture

Aperture is a relatively simple parameter, which is mainly selected according to the requirements of the equipment. However, in order to maintain the stability of the stone saw blade, it is better to use the equipment with a larger aperture for the saw blade above 250MM. The size is 50/60, the inner diameter of 100mm, the larger the hole diameter, the better the fixing performance of the saw blade, the possibility of the saw blade jumping is reduced, but the cutting ability will also be reduced.

5: Choice of thickness

The thickness of the cutting saw blade In theory, we hope that the thinner the stone saw blade, the better, the saw seam is actually a kind of consumption. The material of the alloy saw blade base and the manufacturing process of the saw blade determine the thickness of the saw blade. If the thickness is too thin, the saw blade is easy to shake when working, which affects the cutting effect.

When we choose the thickness of the stone saw blade, the stability of the saw blade work and the material to be sawed should be considered. The thickness required for some special-purpose materials is also specific, and should be used according to the requirements of the equipment. In other words, the thickness of the saw blade is adjusted according to the actual cutting situation. Generally, the thinner the thickness of the saw blade, the higher the requirements for cutting technology, while the thicker saw blade is easier to cut. However, if the cutting parameters can be continuously adjusted according to the actual situation, the choice of thick and thin saw blades is allowed.