The saw blade is indispensable for stone processing. The stone saw blade can directly cut the block stone from the ore body (a wire saw is also used), and then use the saw blade to cut the block stone into plates. Finally, a saw blade is used to cut the board into stone blocks of various sizes. Infer from this, the quality of the saw blade is related to the quality and processing efficiency of the product.

Specification of the saw blade:

The materials for the production of saw blade substrates are mainly 50Mn2V, 75Crl and 65Mn (some low-end markets also use 45# steel. 45# steel is ordinary carbon steel). 65Mn is an ordinary spring steel, 75Crl is a high carbon alloy, and 50Mn2V is a medium carbon alloy steel. The saw blade base of 50Mn2V material has the advantages of many re-welding times, long service life. In addition, the saw blade is not easily deformed after welding the diamond segment, and easy to repair after deformation. The product also has the effect of gradually increasing the rigidity during use. Therefore, 50Mn2V The material is widely used in the production of diamond saw blade substrates.--

According to the specifications, the domestic saw blade processing saw blade substrate specifications start from ф200mm, and the maximum is ф3500mm (the specification of the largest circular saw blade abroad isф5000mm). Among them, the dp200-600ram specification is mainly used for the cutting (edge trimming) processing of semi-finished plates; the ф650 and above specifications are mainly used for the forming and sawing processing of thicker stone slabs (columns) such as tombstones and tomb columns, as well as for the sawing of blocks. Cut into (plate) material processing. At present, the ф1600mm saw blade substrate is the most commonly used.

ф200~600mm saw blade substrate, due to the low technical content, does not require high technology and quality of the product. It only needs to be able to trim and use, and the products on the market tend to be homogeneous. At present, there are nearly 100 domestic manufacturers of saw blade substrates with specifications of ф200-600mm. The market competition is mainly based on price competition. The industry competition is fierce and the profit is very low. However, Some powerful domestic enterprises have no intention to participate in this low-end market competition.

Compared with the size of ф200-600mm, the substrate with a specification of ф650mm or more is more difficult to process. The initial capital to enter the industry is more, and the threshold is higher. Users have higher quality requirements and performance requirements for products. At present, there are not many domestic manufacturers, less than 10. The products show a certain degree of differentiation. The market competition is mainly based on non-price competition. The quality of the product itself, the stability of performance, the length of life and the quality of service. Play a key role in market competition. In southern areas such as Fujian and Guangdong, diamond saw blade substrates are generally used in groups, such as ф940mm, фl600mm, 10 pieces each, ф680mm, фll40mm, and фl600mm, 5 pieces each, etc. The combined saw blade base is used to cut granite and marble slabs in groups, which greatly improves the cutting efficiency and sheet accuracy, saves more than 15% of power consumption, and puts forward higher quality and performance requirements for the saw blade base itself.

Now, with the expansion of the low-carbon concept, the country is paying more and more attention to environmental protection, the mine block resources are in short supply, the supply of power resources is tight, the manufacturing cost of stone saw blade enterprises is rising, and the competition is intensifying.Thus some energy-saving, resource-based and environmentally friendly saw blade substrates are more and more popular in the market, and customers have some new characteristics for the variety of saw blade substrates:

1.Thin, ultra thin saw blade substrate

Thin and ultra-thin saw blade substrates are mainly distinguished by the thickness of the substrate. For ф1600mm substrate, the normal thickness is 7.3mm, the thickness below 6.5mm is called thin substrate, and the thickness below 5.5mm is called ultra-thin sheet body. Using thin and ultra-thin saw blade substrates to cut granite and marble slabs can greatly improve cutting efficiency and block yield, and reduce power consumption. For example, using ф1600mm ultra-thin substrates with a thickness of 4.0mm can improve cutting efficiency by more than 10% , reduce power consumption by more than 20%, and improve the utilization rate of blocks by more than 16%.

Due to the thin thickness and large diameter of the thin and ultra-thin diamond saw blade substrate, the deformation during heat treatment is large, so the control of flatness and HRC by the heat treatment process is very important. At the same time, due to the thin thickness, it is very difficult to adjust the end jump and stress, including the detection. Generally, it is difficult to achieve good results only by manual leveling and detection.

2.Frame saw blade base

The gang saw machine, also known as the diamond big saw, is a new type of frame saw developed in the 1950s. At present, in the developed countries with stone technology, diamond frame saws have basically replaced sand saws in processing marble. Its advantages are: the processing quality is good, the cutting plate is smooth and flat, which can save a rough grinding process; save labor and steel, improve the labor environment, and facilitate management.

3.Ultra-large saw blade base with a diameter of more than 2600mm

At present, there is still a backward method of drilling stone blocks in China, which is not only low in production efficiency but also unsafe in operation, especially due to the rupture of rock mass caused by detonation, serious damage to stone resources, and the size of the produced blocks. Irregular, or even scrapped due to cracks, the yield is very low. It is estimated that only 5% to 25% of the mining volume can be processed into timber using the method of drilling and blasting. Some developed countries in the stone industry have explicitly banned the use of explosive blasting to mine stone materials. International industry professionals believe that China's stone mines have low productivity and serious waste of resources. The main reason is the lack of corresponding diamond saw blade substrates and related mechanized equipment. The mining technology is backward, and the production management is poor.

In addition, the market demand for large slabs of stone saw blades is increasing. In the past, it mainly relied on frame saw blades to process large slabs of stone. However, diamond saw blades and frame saw blades are mainly suitable for cutting soft stones such as marble. For granite and craft stone The cutting still requires a circular saw blade to complete. In order to meet the requirements of domestic and foreign markets, stone processing enterprises will use super-large circular saw blades to cut large slabs, and there will be a peak in recent years.

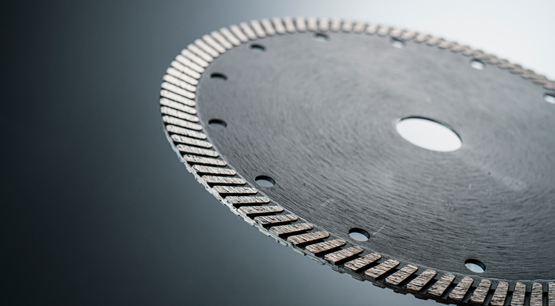

4.Porous saw blade substrate

Compared with the conventional saw blade base, the porous type saw blade base only has several rows of holes processed on the base, and the shape of the holes is mainly water drop type. Judging from the current use of фl600mm porous circular saw blades, the sawing process does not change for stones with a Mohs hardness below 7 degrees, and the porous saw blade matrix has the following advantages compared to the conventional one: (1) It is easy to enter the water, and the cooling effect is obviously improved; (2) The amount of chip removal is increased; (3) The weight of the substrate and the operating load of the saw machine are reduced, and the current is reduced by 5A year-on-year; (4) The operating noise is reduced; ( 5) Due to the reduction of the weight of the substrate, it is possible to load more diamond saw blades for the small combination saw; (6) It can prolong the service life of the substrate, increase the number of cutting square meters, and reduce the welding deformation; (7) Use intermittent, tension recovery performance good. A large number of usage data show that the use of porous saw blade substrate to process stone can not only greatly reduce the power consumption per square meter, but also improve the utilization rate of stone block resources and improve the labor productivity of stone saw blade processing. At present, porous saw blade substrates are not only widely used in the field of stone processing, but also in the field of stone mining, super-large corrugated substrates above ф2600mm are increasingly popularized and used.

With the development of stone industry carpets, the development of stone saw blades will also continue to follow the pace of energy saving.