When we usually use vacuum brazed cutting blades, we often forget some details, and then cracks, drop blocks, and short substrates appear. Part of the reason is the poor quality of brazed diamond saw blades, and part of it is related to the way we use it. We need to pay attention to the following points

1. The operator should wear relevant protective equipment before operation: such as safety shoes, safety glasses, safety helmet, ear protection.

2. The cutting machine should have a protective cover or other safety device.

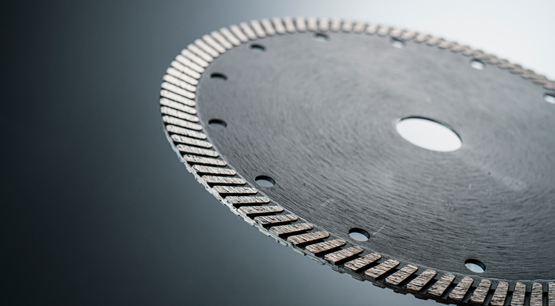

3. Before use, check whether the cutting blade is damaged or not, if it is seriously deformed, it is strictly forbidden to use it.

4. Check whether there is dirt on the chuck of the cutting machine. If there is dirt, clean it before installing it. Whether the spindle bearing or spindle or bushing is seriously worn, operators need to replace the new bushing or equipment when the wear is serious.

5. During installation, the direction marked on the brazed cutting blade must be consistent with the rotation direction of the cutting machine. Inconsistent directions can easily lead to the phenomenon of not cutting.

6. If it is wet cutting, please add enough cooling water.

7. If dry cutting is used, the dry cutting must be idling for a few seconds every 10~15 seconds to cool the cutting blade. For larger cutting depths, it should be cut in steps. When the dry cutting saw blade is cooled with water, the effect will be better.

8. Curve cutting and side grinding are not allowed during the cutting process. The use of curved cutting and side grinding may easily cause cracks in the brazed cutting sheet, drop blocks or break the substrate.

9. If the cutting is oblique cutting, the cutting depth should not be too deep. You must pay attention to safety during the cutting process. Try not to let your body and the cutting blade be on the same plane. If you hear any abnormal sound during the cutting process, you should stop cutting immediately. Check the saw blade if is damage, or check if the blade fixing screw is loose.

10. If the brazing cutting blade is blocked during use, the cutting blade and saw blade will become blunt. Please use a ceramic grinding wheel or refractory brick to re-blade (cutting a dozen knives on a ceramic grinding wheel or refractory brick) , the sharpness can be restored after re-blade.

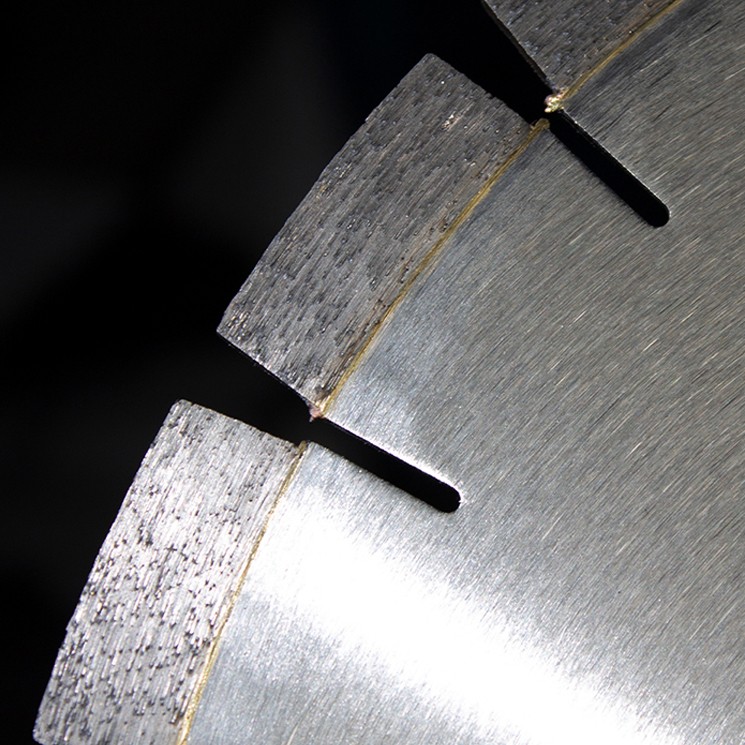

11. When there is noise and severe vibration during the cutting process, you should stop immediately and check whether the cutting blade has cracks or dropped blocks. If there are cracks and blocks, it needs to be replaced with a new one.

12. When cutting, the segment of the cutting blade exceeds the cutting material by more than 2mm, which can reduce the degree of edge chipping.

13. If the diameter of the brazed cutting blade does not match the main shaft of the cutting machine, a suitable size washer can be used, but during the cutting process, whether there is jitter should be pay attention to, and if so, check whether the washer falls off.

If the washer falls off and continues to be used, it is easy to cause shaking during cutting, and eventually the cutting blade is out of round and cannot be used continuously. Out-of-roundness means that one side of the brazed cutting blade has more wear, and one side wears less. You can see the difference in the degree of wear between the height of the blade and the appearance of the blade.