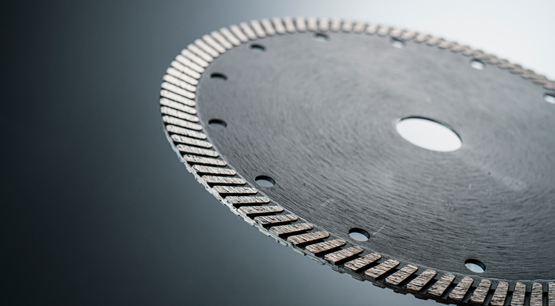

Diamond saw blade is a commonly used cutting tool. There are many precautions in the use process. This article provides correct and standardized sawing instructions based on common problems encountered in diamond sawing in daily work, aiming to help customers better use LINSING diamond saw blade products.

There are many points that need to be paid attention to in the cutting process of the diamond saw blade. If the saw blade is used correctly, it will greatly increase the service life of the saw blade and greatly help the cutting quality. Let's take a look at them one by one:

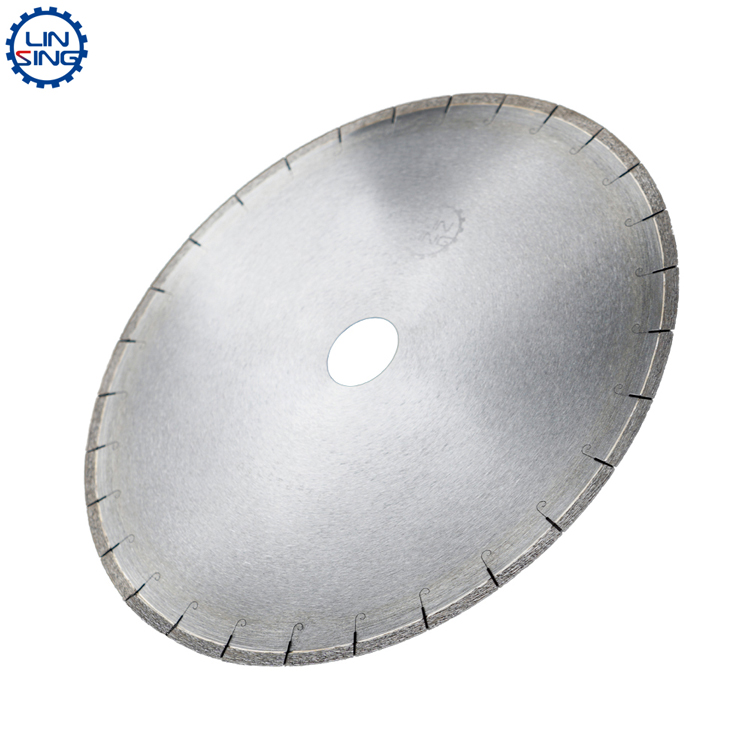

1.When placing the saw blade in the stone factory, many factories will directly place the saw blade on the ground. This is not a good practice. The correct way is to hang the diamond saw blade vertically on a dry rack and avoid damp places. Do not lay the diamond saw blade flat on the ground or on the shelf. Placing it flat will cause the alloy saw blade to deform, and it will also cause the hidden danger of the blade falling off when the saw blade is cut. The oblique placement will have a serious impact on the cutter head on the lower side of the saw blade that is in contact with the ground, which is not conducive to cutting.

2. When using the saw blade, do not exceed the specified rotational speed. The higher the linear speed, the sharpness will decrease and the diamond segment will be ground when cutting some stones with higher hardness or stronger abrasiveness. And if the customer buys the ordinary saw blade products of LINSING Company, it is better not to exceed 260 rpm. Too high speed will produce huge amplitude, and there are higher requirements for the material of the saw blade substrate. If you need more For high-speed diamond saw blades, please contact us for customization.

3. During the normal cutting and use of diamond saw blades, operators must wear protective equipment such as protective covers, gloves, hard hats, labor insurance shoes, and protective glasses. If there is large dust, masks are also necessary.

4. When installing a diamond saw blade, we must first confirm the performance and purpose of the cutting machine, and read the machine manual first, so as not to install it wrongly and cause an accident. Especially for the operation of installing the saw blade, carefully follow the operation manual and install according to the standards and procedures.

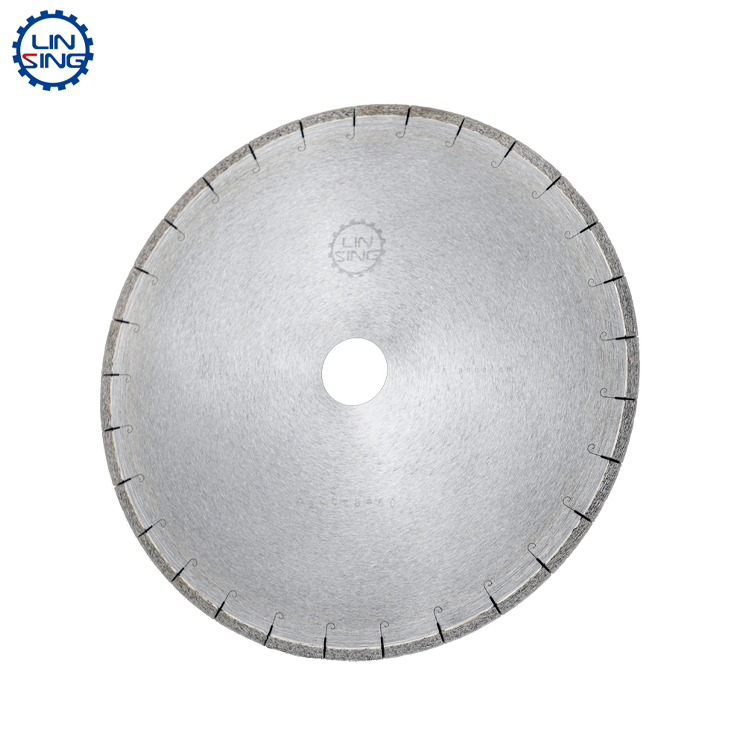

5. When installing a diamond saw blade, we must first check whether the saw blade is cracked, distorted, flattened, or missing teeth, etc., and then install it. If the above occurs, please contact us in time. Do not continue to install and use the product in question to avoid major cutting problems.

6. The teeth of the diamond saw blade are very hard and sharp. It is forbidden to collide and fall to the ground. It must be handled with care. When moving, it is recommended to move vertically. If it is a large saw blade, when using a row crane to move, it is also moved vertically through the rope around the inner hole.

7. After installing the saw blade, be sure to confirm that the hole of the saw blade is firmly fixed on the flange of the saw table. When there is a washer, the washer must be properly fitted; then, gently push the saw blade by hand to confirm whether the saw blade rotates eccentrically. If you are not sure whether it is shaking, you can start the machine and run it for a period of time to make sure that the machine and saw blade are running normally before putting in the stone.

8. The cutting direction indicated by the arrow on the alloy saw blade must be aligned with the rotation direction of the saw table. It is strictly forbidden to install in the opposite direction, as the wrong direction will lead to tooth loss and even more serious cutting accidents. The main reason is that the blade of the saw blade is edged at the factory. If it is cut in the opposite direction, the exposed diamond will not only be difficult to cut the stone, but will be easily broken, resulting in insufficient exposed part, and insufficient cutting space, resulting in the stone cutting not moving or sawing. The film is distorted, etc.

9. Pre-rotation time: After replacing the new saw blade, it needs to be pre-rotated for 2-5 minutes before use, so that the saw table can only be cut when it enters the working state.

10. Before cutting, it must be confirmed whether the purpose of the saw blade is consistent with the material being cut. The uses of diamond saw blades are roughly divided into 6 categories, namely granite saw blades, marble saw blades, quartz stone saw blades, microcrystalline stone saw blades, artificial stone saw blades and current slate saw blades. Before purchasing, you should find out the material, hardness, abrasiveness, etc. of the cutting material. It is better to have the inspection report of the cutting object, so that it is more convenient for LINSING staff to quote you and match the suitable saw for various stone cutting situations. tablet product. Of course, if customers have specific cutting requirements, they can also be put forward together.

11. When cutting the material, the saw blade in normal operation must be gently cut into the material, and it is forbidden to press and push hard. The feed speed of the diamond saw blade with the new diamond segment should be controlled at about 30%-40% of the actual feed speed.

12. Sudden reversal is prohibited, as reversal will lead to tooth loss and danger.

13. If you hear abnormal sound during use, see abnormal shaking and uneven cutting surface. Please stop the operation immediately, find the cause of the abnormality, and replace the saw blade.

14. When cutting, it is forbidden to stop the saw blade suddenly in the middle of the object to be cut. Stopping in the middle of the cutting object will cause the sawtooth to fall off and the saw blade to deform.

15. To prevent the saw blade from rusting, please wipe the anti-rust oil in time after cutting..

16. When the teeth on the diamond saw blade are not sharp, you need to grind the teeth again, and you must take them to a grinding shop designated by the manufacturer or a shop with grinding technology. Otherwise, the original angle of the saw blade will be damaged, the cutting accuracy will be affected, and the service life of the saw blade will be shortened.