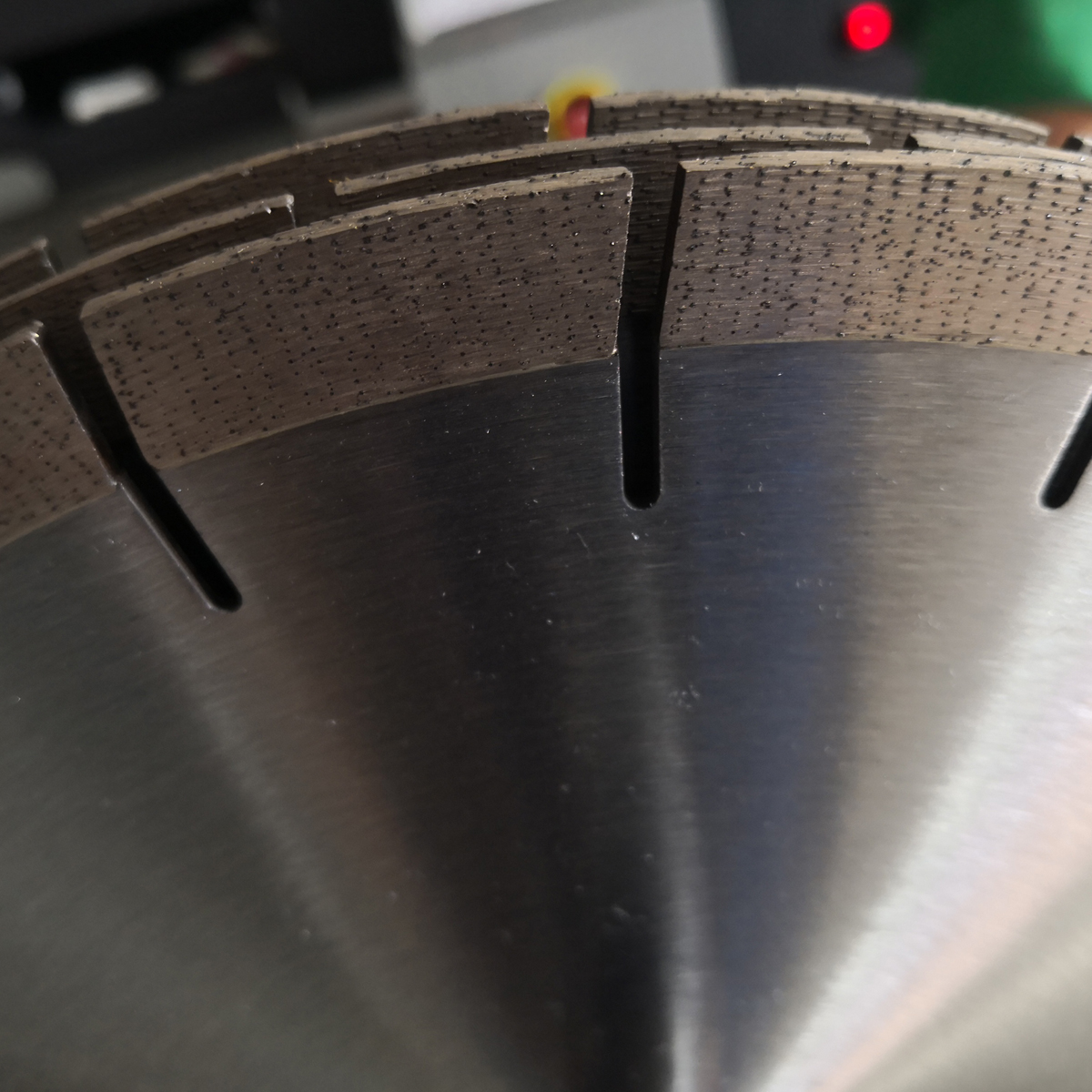

Orderly arranged diamond saw blades, in the field of stone (granite slabs/marble slabs/ceramic slabs/microcrystalline stone slabs, etc.) real economic benefits. The reason is that the current application cost of this technology is very high, and it is difficult to introduce it into the production field for Chinese stone tool manufacturers.

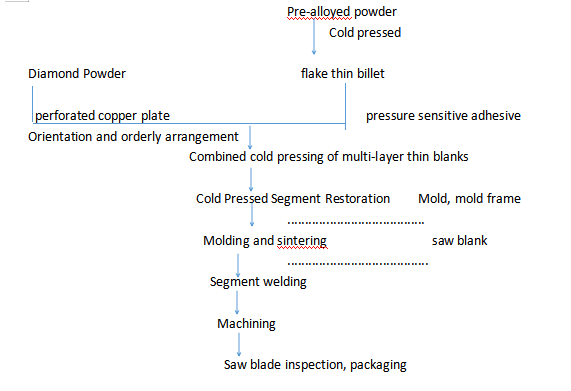

The cutting segment of diamond saw blades arranged in an orderly arrangement is quite different from the ordinary diamond cutting segment in the preparation process (as shown in Figure 1).

There are some procedures.

(1) The upper pressure head of the automatic cold pressing die must be processed, and the dot matrix small ball columns should be pre-designed and distributed on the top of the upper pressure head; (2) The pre-alloyed matrix powder and the diamond single crystal are granulated separately, so that the diamond single crystal is made into spherical particles of uniform size during the coating granulation process; (3) Adjust and transform the program of the automatic cold press, put the diamond particles and the matrix powder into the hopper of the automatic cold press separately, and realize the separate feeding of the matrix powder and the diamond; (4) After the matrix powder is unilaterally fed , be sure to press the carcass powder into small flakes; (5) During the pressing process, the upper indenter has a predetermined arrangement of raised ball columns, so that the surface of the carcass sheet is pressed with small round pits corresponding to the predetermined arrangement; (6)Drive the diamond feeder to feed the material, and drop one spherical diamond grain into each round pit, then scrape off the excess diamond, and then lightly re-press once, and the diamonds are arranged in an orderly thin compact to complete the forming ,as shown in picture 2:

A brief description of the above key process technologies for the production of arix diamond saw blades:

A brief description of the above key process technologies for the production of arix diamond saw blades:

1. Diamonds cannot be naturally oriented and arranged in an orderly manner in the pre-alloyed powder, so the matrix powder must be cold-pressed into a sheet-like thin billet, and then the diamonds are arranged in an orderly manner on the thin billet. The number of layers of the thin blank in a segment is calculated according to the designed number of diamond layers (the number of layers of the thin blank = the number of diamond layers - 1). The amount of powder used for each layer of thin billet = the total weight of the segment / the number of layers of thin billet.

2. According to the diamond arrangement designed by calculation and simulation, use a low-to-medium power laser to drill regular hexagonal holes on the copper template. The thickness of the selected copper plate is slightly larger than the average diameter of the diamond, about 0.5mm, so as to ensure that the diamond can completely fall into the hole. The size of the hole should be greater than 1 time of the average diameter of the diamond and less than 2 times of the average diameter, so as to ensure that each hole can accommodate one diamond, but not two diamonds. Moreover, the diamond single crystals falling into the hole have the same orientation, with a ratio of 75%, so as to realize the directional distribution of the diamond single crystals.

3. Spray a thin layer of special pressure-sensitive adhesive on the thin blank of the carcass, then cover the perforated copper template on the thin blank. Sprinkle the diamonds on the copper plate, then sweep the diamonds into the holes, making sure there is a diamond in every hole. Uncover the perforated copper template, and the diamonds form an orderly arrangement on the carcass.

4. Combine multi-layer thin blanks with oriented and ordered diamonds, and use a cold press to form the shape of the segment. In order to eliminate the sprayed pressure-sensitive adhesive as much as possible, put the cold-pressed segment into the vacuum sintering furnace , Place it at a temperature of 400°C for about half an hour to fully volatilize the pressure-sensitive adhesive. 5. The diamond segment out of the sintering furnace is molded together with the pressed one, and then hot-pressed and sintered. During sintering, vertical die loading and horizontal pressure should be adopted to ensure that the diamond particles are still arranged in an orderly manner after sintering.

5. The diamond segment out of the sintering furnace is molded together with the pressed one, and then hot-pressed and sintered. During sintering, vertical die loading and horizontal pressure should be adopted to ensure that the diamond particles are still arranged in an orderly manner after sintering.

6. Then remove the mold, grind the arc, weld, sharpen the edge, and trim.

The production process of diamond saw blades arranged in an orderly arrangement for each unit takes an average of more than 30 minutes longer than the production of normal diamond saw blades, plus the investment in supporting equipment, the addition of auxiliary facilities, and the demand for high-skilled workers , so that the development and production costs of orderly arranged diamond saw blades are high, and the market benefits are still unclear, which is difficult to be generally accepted by the current Chinese stone tool industry. Therefore, we believe that the application era of arix diamond saw blades in a strict sense has not yet come.