Diamond segments are also called diamond caking, sawtooth etc. which are a kind of diamond tool products often used in the sawing process. Diamond segments are generally not used alone, and can be welded to the saw blade substrate to form a diamond circular saw blade, it can also be welded to the gang saw matrix to form a gang saw, or welded to the metal iron plate, bowl mill, drill bit and other matrix components to form diamond grinding discs, diamond bowl mills, diamond drill bits and other products. It can be said that in stone processing, most of the processes such as grinding, drilling and cutting are completed by diamond segments. Without diamond segments, many processes cannot continue normally, so diamond segments are the most important basic tools and materials in the whole stone industry.

The composition of the diamond segments is divided into three parts, these three parts are combined by physical high temperature and high pressure, then form an ultra-high hardness industrial products. That is not only taking into account the hardness of diamond, but also reducing the cost. It is safe to say the diamond segments has fundamentally changed the problems of high price of stone and difficult processing. Therefore, the diamond segments is also called “the driving engine of the modern stone processing industry”, it goes without saying that the importance of the diamond segments.

The first formula of the diamond segments is synthetic diamond, because diamond is the hardest material in nature, put a certain size of diamond into the segments, and cut the stone through the super hard physical properties of diamond. That’s a core principle of the sawing of stone processing.

The second formula of diamond segments is the matrix material. The matrix material is composed of many different matrix powders. The diamond and matrix powder are bonded through the processes of stirring, cold pressing, molding, sintering etc. then form to diamond segments. In the past, most of the diamond segments are consisted of diamond and matrix materials, but now, diamond segments are divided into layers, and the interlayer’s material is the third formula of our diamond segments.

The sandwich material is divided into powder interlayer and iron sheet interlayer. That’s a process improvement to improve the sharpness of the diamond segments. Not all segments need this part of the material, because of the requirement for diamond holding power is very high, a little carelessness will cause the diamond to fall off. So many diamond segments manufacturer is difficult to control that layer segments processing technology.

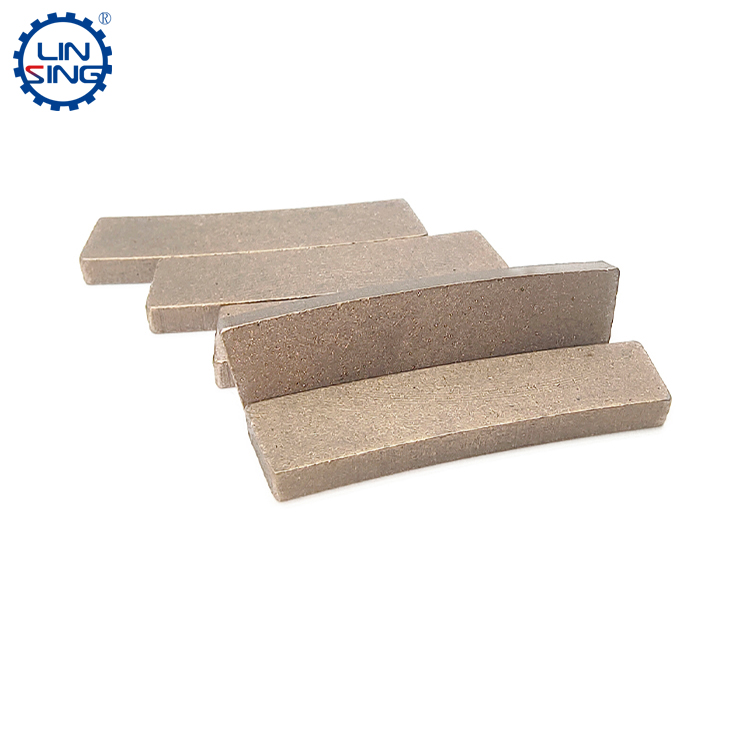

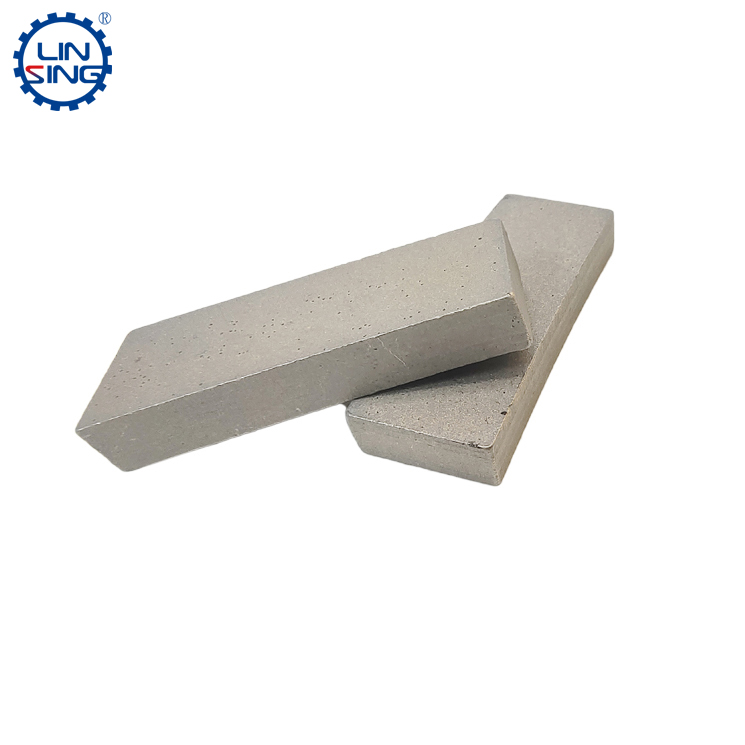

I believe that after knowing so much, everyone has their own understanding of diamond segments. Generally speaking, the Super hard diamond segments are made of different matriexes and various shaped such as ARC- shaped, rectangular, M-shaped, K-shaped, W-shaped, T-shaped etc. and it is used for welding on common stone processing tools and can be replaced at any time, that means our diamond segments not only can save the processing cost , but also is an easy maintained stone processing tool.

The definition of Diamond segments

Publish date:2022-07-05 15:39:21 Article From:Linsing Diamond Tools Clicks: