In daily applications, people like to process diamond segments into different shapes to meet the cutting needs of different stones. As the shape of the diamond segments continues to increase, people find that the different shapes of the diamond segments directly affect the diamond saw blade sawing performance and has an extremely important impact on improving the life and sharpness. It can be said that the shape of the diamond segments not only improve its outlook, but also have a great significance in terms of practicability.

The specific function of the diamond segments is to improve the saw blade chip holding capacity, chip removal capacity, cooling and lubricating effect of diamond segments in the arc cutting area of the saw blade. In addition, it can also reduce the friction effect between segments and stone and sawdust, and improve the rock-breaking ability of diamond particles (as we often say to improve the sharpness),thereby reducing energy consumption (saving power and manpower), improving the performance of the saw blade and so on.

What are the shapes of diamond segments in recently? As far as Linxing diamond tools are concerned, there are M-shaped, R-shaped, Z-shaped, V-shaped, K-shaped, W-shaped, U-shaped etc. which are common edge geometry shapes, and these different geometric shape can also be designed as ordinary convex section, layered "sandwich" concave section, "L" shaped section, stepped section, segmented section and side grooved section etc.

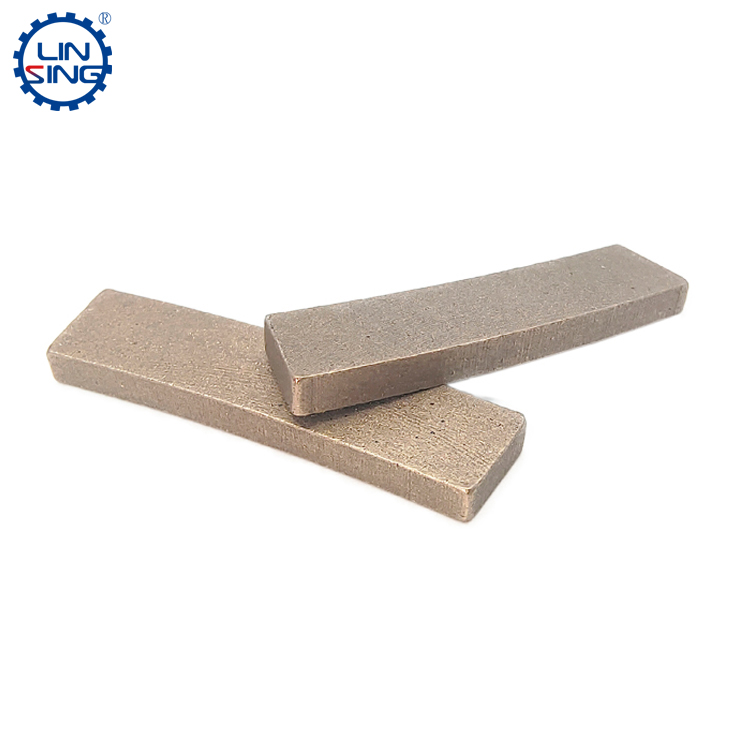

The shape of diamond segments increasing is along with people keep exploring the function of diamond segments, and then work out the solutions. The earliest segments are cuboid, and it is found that there will be serious wear on both sides, but not much wear on the middle part when cuboid segments are used for circular saw blades. After long-term cutting, the segments will become convex in the cross-sectional direction, and the area of the working surface of the segments and the stone will be increased, and the diamond will be easily blunt. Due to the increase of the cutting force, the saw blade substrate is prone to deformation, which shortens the life of the saw blade substrate. Of course, the uneven abrasion of diamond segments will result in the stone with more serious issue of different thickness and uneven cutting surface. Therefore, the design of the diamond segments needs to be more sharper, more reasonable waterway design, and better chip removal function, those become an important reason for the diverse shapes of modern diamond segments.

However, due to the rich variety of stone in the world, different machines and substrates have a great influence on the segments, the specific situation can only be adjusted to the shape of the segments. At present, all segment shapes are independently designed by each manufacturer and there is no unified standard. So it also caused the updated segment shape even worse than the previous one.

Why The Diamond Segments Have Been Processed Into Vavious Shape?

Publish date:2022-07-05 16:03:13 Article From:Linsing Diamond Tools Clicks: