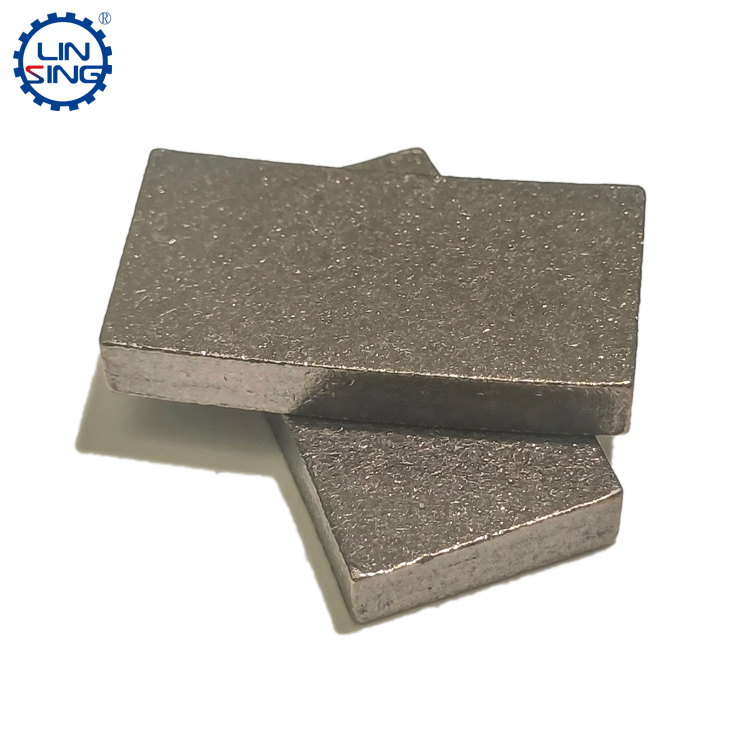

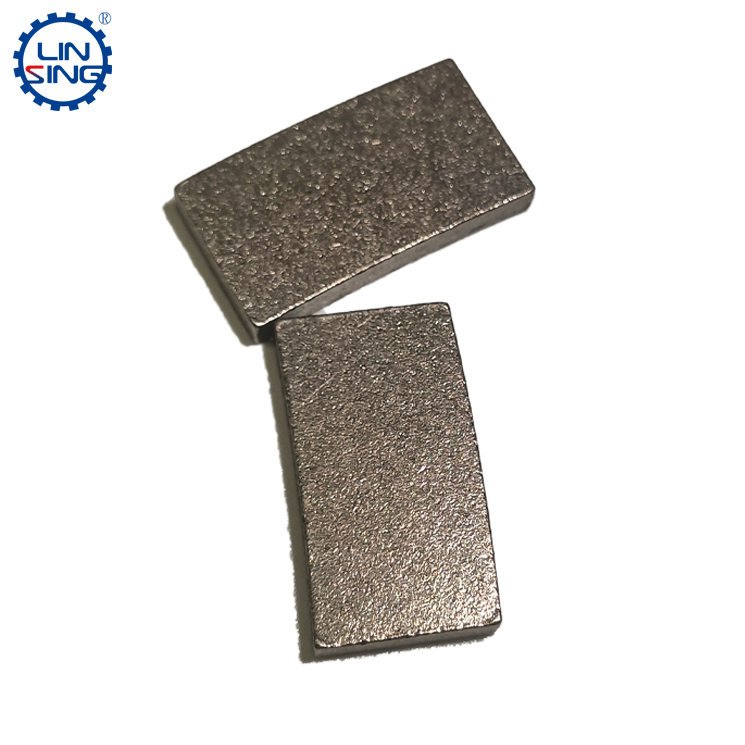

Diamond segment is a non-standard product. Although the shape of each manufacturer uses graphite molds for production, the size and specifications are also very consistent, but if you observe carefully, you will find that the segments produced by each manufacturer are different, such as the color. Different colors have great differences in the highlighting of diamond particles. In fact, even if the same manufacturer faces different cutting objects of different customers, most of the segments produced are different.

Each segment is adapted to its scene. It is difficult to have a segment that can achieve perfect cutting with any material. The main reason is that the sharpness and lifespan of the segment are two opposite attributes, plus the different hardness of the stone. Different abrasiveness will cause many kinds of stone cutting scenes, such as marble, which belongs to medium-hard stone and medium-hard abrasiveness, so the sharpness must be considered, except for sharpness, cutting edge, cutting speed, etc. It must also be taken into consideration, and then continue to consider the cutting life, segment chip removal, whether to muffle and other issues, and finally design the most cost-effective segment product.

So what factors need to be considered in diamond segment customization? How do these factors affect the cutting efficiency and lifespan of the segment? How to adjust the segment formula to make the diamond segment more in line with the needs of buyers? here we come to find out:

The hardness of stone: This is the first factor to consider. Stone is a hard material in nature, but the hardness is also different. Soft stones such as talc, calcite, gypsum and other materials are all natural stones. These stones The hardness is low, and the Mohs hardness is only about 3. Ordinary granite stone has a Mohs hardness of 7-8, while superhard corundum and diamond have a Mohs hardness of 9-10. Most hard stone is cut hard, so when we design the segment, we must Use a bond that is harder than stone. Note that the bond cannot be too hard. If it is too hard, the bond will not be consumed in the process of cutting the stone, and will eventually be polished, and then it needs to be re-edged, reducing the processing efficiency and increasing the cost of the blade.