Diamond circular saw blade is a common cutting tool in daily life, which is widely used in the processing of hard and brittle materials such as concrete, refractory materials, stone materials, and ceramics. At present, some diamond circular saw blades can cut metals such as steel, and with the wide application of artificial stone and new energy-saving materials, the application range of diamond circular saw blades continues to expand. It is also widely used in materials such as slate.

The diamond saw blade is mainly composed of two parts: the steel base and the diamond segment. The common main materials of the matrix are various alloy steels, including high manganese steel, high-speed steel and other materials. The diamond segment is the part that plays a cutting role in the entire cutting process. Due to the severe friction with the cutting material for a long time, the diamond segment will be continuously consumed. While the substrate will not be consumed, so the saw blade exceeding 230mm, The cost of replacing a pair of diamond segment is far less than replacing the entire saw blade. Of course, the reason why the diamond segment can cut is because the diamond segment contains diamond. As the hardest material at present, diamond is the hardest material at present. According to the characteristics that the stone from other mountains can attack jade, the diamond continuously cuts the processed object through friction, and finally completes the cutting process.Then we can start to classify the appearance of diamond circular saw blades.

Appearance classification of diamond circular saw blades:

1: Clasfication of the size of the saw blade. The diamond saw blade can be divided into large saw blades (saw blades with a diameter greater than or equal to 900mm), medium-diameter saw blades (saw blades with a diameter of 300-850mm), and small saw blades (with a diameter of 105-250mm) small slices), engraving blades (small saw blades with a diameter of 50-95mm).

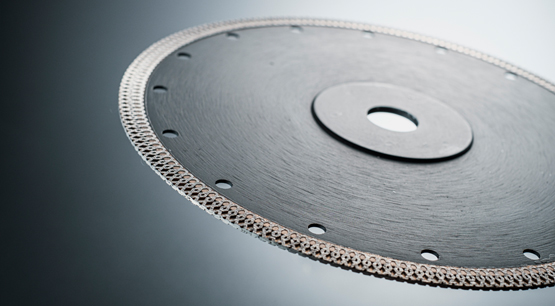

1. Continuous edge saw blade. Continuous serrated diamond saw blade is generally made by sintering method. Bronze bond is often used as the basic matrix material. Water must be added during cutting to ensure the cutting effect, and use the laser to cut the type of slit with the diamond segment.

2. Diamond segment type saw blade. The sawtooth is broken, the cutting speed is fast, and it is suitable for dry and wet cutting methods.

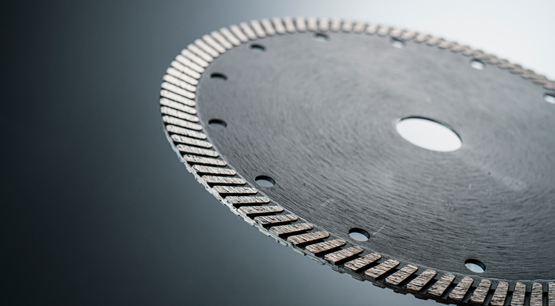

3. Turbine saw blade. Combining the advantages of 1 and 2 above, the saw tooth continuously presents a turbine-like uniform convex and concave, which improves the cutting speed and prolongs the service life.

Different materials use different types of diamond saw blades, and different powder formulas are suitable for the characteristics of different materials, which directly affects the quality, effect, qualification rate and even cost and benefit of material products.

Factors affecting the efficiency and life of diamond circular saw blades include sawing process parameters, diamond particle size, concentration, and bond hardness. According to the cutting parameters, there are saw blade linear speed, sawing concentration and feed speed.