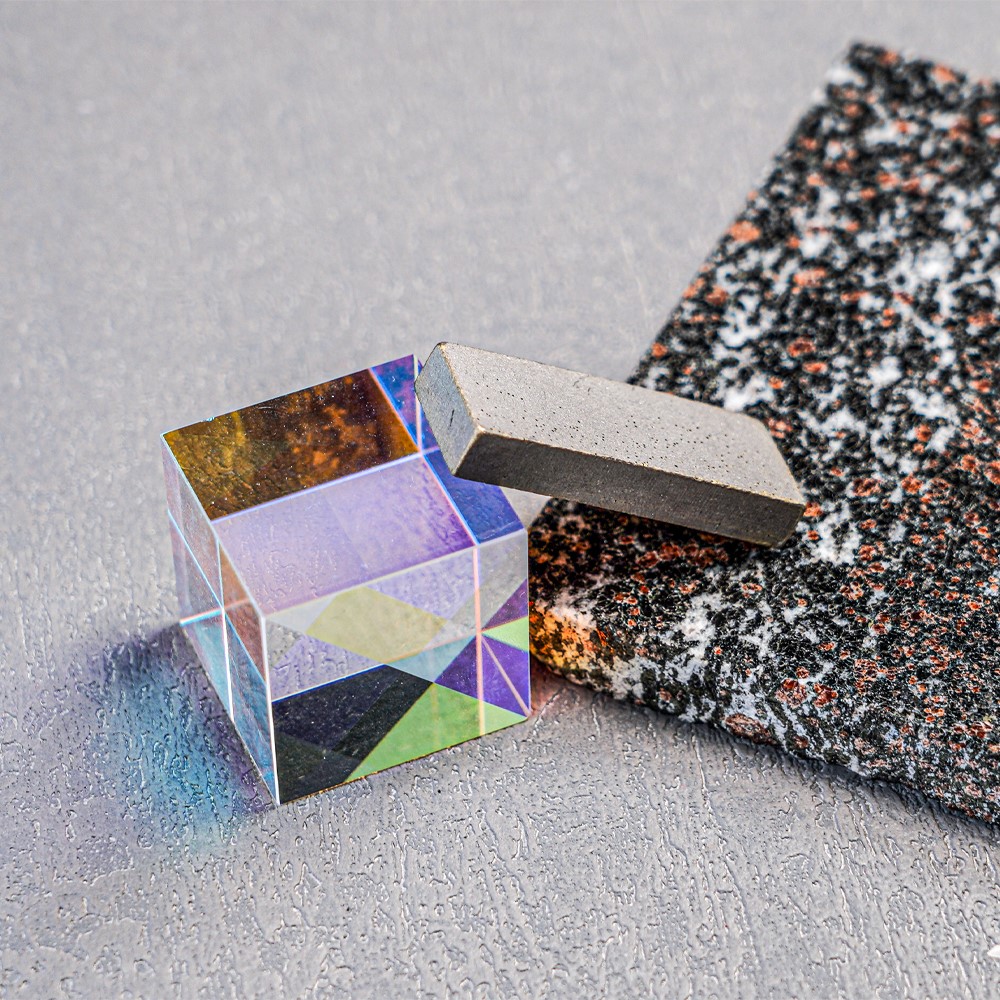

The diamond segment is a kind of combination of diamond and metal powder through high temperature and high pressure sintering. Due to the different particle size, strength and adjustable concentration of diamond, as well as the difference in metal powder ratio and metal ratio composition, diamond segments also exhibit a variety of cutting properties and can cut many different materials.

In addition, in the actual application process, diamond segments are widely used in stone cutting and reinforced concrete cutting. In the specific cutting process, the difference between the segments of these two materials is mainly reflected in the following points.

1. The diamond particle size in the diamond segment is not the same. Because the hardness of the stone can be covered from Mohs hardness of 3-8, when cutting the stone, it is necessary to distinguish the hardness of the stone. If the hardness of stone is low, It can be cut by using a mixture of large-grained diamond and medium-coarse-grained diamond. If the hardness of the stone is higher, it is necessary to use diamond with a smaller particle size, which can prevent the diamond from breaking during cutting and reduce the loss. In the same way, when cutting reinforced concrete, it also needs to be determined according to the hardness and characteristics of the steel-concrete structure. For example, if the steel content is less than 3% of the cross-section, it belongs to the category of low steel bar cutting. If the cross-section of the steel bar exceeds 8%, it belongs to the high steel. The diamond used in these two types of segments decrease in grain size as the cross-section of the rebar increases. And reinforced concrete depends on the structural strength of steel-concrete stones and concrete. For example, the steel-concrete buildings used to build bridges and piers are stronger than many multi-story buildings.

In general, the grain size of diamond decreases as the hardness of stone or concrete increases, but generally does not exceed 120 mesh, otherwise it will not have cutting performance. Most of the stone cutting uses 50-60 mesh diamond. Most of the steel-concrete structures are 80-100 mesh.

2:.The strength of diamond is different. Generally speaking, when diamond is cutting metal, due to the brittleness of diamond, it is easy to break. However, when cutting concrete, the saw blade needs to have some tenacity. Therefore, the choice of diamond with higher strength has become an inevitable choice.

The diamond strength determines the cutting impact resistance of the diamond segment, and it will not be broken if it is impacted, so that the cutting ability of the diamond segment can be fully utilized. But for stone, in addition to hard granite and quartz, which require higher-strength diamonds, most other stones do not require high-strength diamonds, so if you use ordinary stone saw blades to cut steel mixes, it is easy to appear the problem of lifespan is greatly reduced.

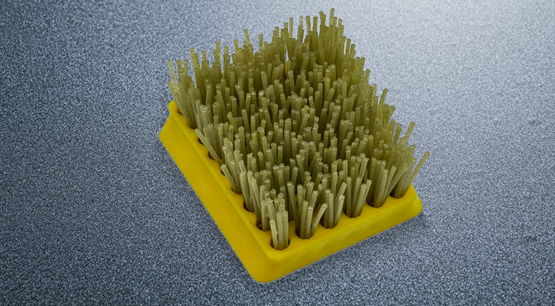

3. The carcass material is different. The metal matrix determines the holding force of the diamond, and the wear resistance determines the service life of the diamond segment. During the process of cutting metal, the matrix binder will also be rapidly consumed. If the matrix is consumed too fast, the cutting will be huge. The most direct manifestation is that the life of the carcass is greatly shortened. Therefore, the wear resistance of the matrix material is very important. The wear resistance of stone is far less than that of steel bars. Adding materials that are harder and more wear-resistant than steel is the only solution.  4: The shapes are different. Most of the stone cutting segment’s shapes are R-shaped, parallel, M-shaped, and very few use single-sided corrugated saw blades and short-toothed saw blades. Most saw blades have a good performance in the process of cutting stone, but the fan-shaped saw blade can hardly complete the cutting of steel mix, which is the biggest difference between the two blades.

4: The shapes are different. Most of the stone cutting segment’s shapes are R-shaped, parallel, M-shaped, and very few use single-sided corrugated saw blades and short-toothed saw blades. Most saw blades have a good performance in the process of cutting stone, but the fan-shaped saw blade can hardly complete the cutting of steel mix, which is the biggest difference between the two blades.

Stone and steel mixed cutter segments are quite different in terms of formula and structure. The two are not the same, so they must not be mixed.