The following points should be paid attention to during the operation of the diamond saw blade.

1.Precautions before use

(1)Please pay attention to protective measures, such as protective glasses, masks, gloves, etc., be sure to use a saw machine with a protective cover

(2)When installing the saw blade, be sure to tighten the fastening nut to prevent the saw blade from jumping during use.

(3)Please note that the installation direction is consistent with the direction of the cutting equipment.

(4)Clean the surface of the cutting equipment before use, and do not have steel bars, iron wires and items that are easily entangled, which may easily crack the saw blade. If there are sundries and debris during use, please clean up in time.

2.Precautions in use

When the diamond saw blade is cutting, it will generate heat. In order to avoid the deformation of the saw blade and the shortening of its life, please ensure the following cutting conditions when cutting:

(1) Sufficient water supply (water pressure greater than 0.1Mpa)

(2) The water supply pipe is in the cutting part of the saw blade

(3) If the water supply is interrupted unexpectedly, please restore the water supply as soon as possible, otherwise it is recommended to suspend the cutting.

The diamond saw blade is mainly used in the wall saw cutting machine. During the use process, it is used at a constant speed of 2-2.5 meters per minute. Change the cutting speed arbitrarily, or even increase the cutting speed, which exceeds the capacity of the saw blade, otherwise it will easily cause the deformation of the saw blade.

When the diamond saw blade is cutting, if there is a power failure or cutting equipment failure, please stop the machine immediately and remove the saw blade, otherwise the saw blade will be broken and damaged and cannot be used.

3.Other matters needing attention

(1)When working, the workpiece should be fixed, and the profile positioning conforms to the cutting direction, so as to avoid abnormal cutting. Do not apply side pressure or curve cutting, and feed the knife smoothly to avoid the impact of the blade contacting the workpiece, which will cause the saw blade to break or the workpiece to fly out, resulting in an accident.

(2)When working, if abnormal sound and vibration, rough cutting surface, or peculiar smell are found, the operation must be terminated immediately, and the inspection must be carried out in time to eliminate the fault to avoid accidents.

(3)When starting and stopping cutting, do not feed too fast to avoid broken teeth and damage.

(4)If cutting aluminum alloys or other metals, use special cooling lubricants to prevent overheating of the saw blade, resulting in tooth paste, and other damage, affecting the cutting quality.

(5)The equipment chip removal groove and slag suction device ensure smooth flow to prevent the slag from accumulating and affecting production and safety.

(6)When dry cutting, please do not cut continuously for a long time,so as not to affect the service life and cutting effect of the saw blade; for wet cutting, water should be added to cut to prevent leakage.

Operation Process Of Diamond Saw Blade

Publish date:2022-07-19 11:57:25 Article From:Linxing Diamond Tools Clicks:

Diamond Wire Saw For Marble Mining&Quarrying

Diamond Wire Saw Beads

Diamond Wire Saw For Granite Quarrying

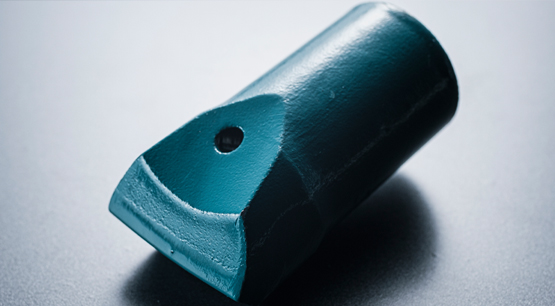

Taper Chisel Bit

Cross Chisel Bit

Related News

Related Knowledge

Brazed diamond cutting blade is a very special diamond tool This saw blade uses vacuum brazing to fix the diamond on the saw blade substrate The entire saw blade has a simple structure and less sintering and welding processes, the stability is higher This article mainly introduces the advantages and disadvantages of brazed diamond cutting discs

07/04

2022

Why Are Super Large Diameter Diamond Saw Blades Not Used For Block Cutting?

Diamond saw blades have great application differences according to the change in size For example, the size of the saw blade for cutting blocks is mainly concentrated in 900-3500mm Why aren t super large diameter saw blades used for block cutting? What s the difficulty? Can it be solved? These are the questions to be discussed in this article

07/04

2022