In stone producing process, especially granite, due to its high hardness, the current widespread use of multi cutting granite block material, the current stone factory more than 3 pieces, 5 pieces, 7 pieces, 9 pieces, 10 pieces, 12 pieces and other saws Chip combination, in the processing process, the segment will have a lot of problems, of course, there are some stone mills will use one-arm combination cutting, these machinery using 6 + 6, 8 + 8 and other sizes of two sizes of saw blades, later there will be a special article about the one-arm combination cutting segment problem, This article is more than a introduction.

The biggest feature of this multi-blade bridge combination is that it is combined with different sizes, with a minimum blade diameter of 460mm and a maximum blade diameter of 3500mm, but the thickness of the substate is consistent, which in turn leads to the size of the segment. Because of this special combination, there are a number of problems in the processing of granite, let's take a look at:

1: Multi-blade bridge cutting in the cutting process of smaller diameter saw blade segment consumption will be faster: in the early stages of stone cutting, first use small saw blades for cutting, and then large saw blades to cut, start the process, because the large saw blade does not Start work, small saw blade under greater pressure, natural consumption will accelerate; Cut the same area of stone, consumption is naturally smaller.

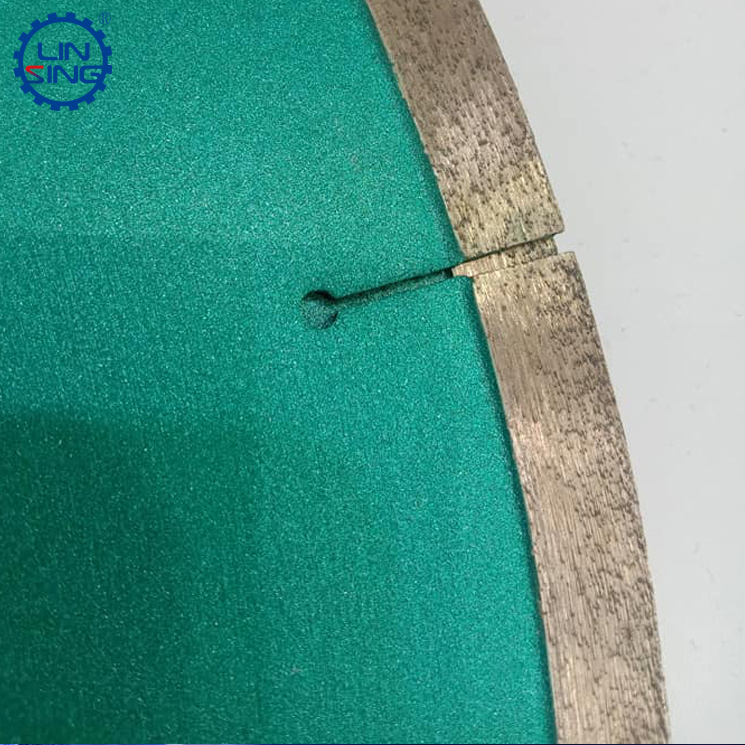

2: Multi-blade cut in the cutting process, the diameter of the smaller saw blade will appear to turn the situation: the specific performance is that the layer of the compartment segment of the work layer offset to both sides, while the middle part of the working layer is bent inward. This situation is mainly due to the start of machinery to start cutting stone process, the pressure is too large, resulting in deformation of the segment. Or in the processing process, there is insufficient cooling water, the segment due to high temperature deformation. If this is the case, the best solution is through the secondary cutting edge, the tip part of the tip of the tip polished off, and then start cutting again, but be sure to pay attention to the pre-cutting, reduce the speed of the cut, and give enough cooling water (also not too much lead to the segment slip).

3: The problem of skewing of the segment cutting: this problem is also known as segment defleaing, may cut machine adjustment uneven, spindle tilt or wear problems, or diamond segment bond is too soft, resulting in uneven force, saw blade installation inequality reasons. The specific solution is: if there is a problem with the machinery, replace the spindle or repair related components, if there is a diamond problem, the short-term solution is to carry out grain re-welding, that is, a segment soldered between the front and back of the segment, and the long-term solution is to adjust the hardness of the diamond tire binding agent to meet the needs of the current cutting material, if the problem of saw blades, the need for better flat saw blades, and then vertical testing.

4: The segment arcing, mainly reflected in the segment on both sides of the grinding, but the middle part is less consumption, such a situation is generally caused by the blade bias, due to the blade on both sides of the blade, resulting in serious wear on the side of the diamond segment. In this case, the blade needs to be adjusted or replaced for treatment. Segment arcing may also be the segment design is unreasonable, the bond on both sides of the segment is too soft (such as sandwich segment), there will be a similar situation, the solution is to find a more professional diamond segment manufacturers, such as Linxing Diamond Tools Co., Ltd., specializing in the production of diamond segment and rope saw products, because we mainly do segment, so we are more professional.

website:https://www.linxingstone.com

Summary of segment problems in the multi cutter bridge in cutting stone process

Publish date:2022-07-07 17:07:02 Article From:Linsing Diamond Tools Clicks:

Diamond Wire Saw For Marble Mining&Quarrying

Diamond Wire Saw Beads

Diamond Wire Saw For Granite Quarrying

Taper Chisel Bit

Cross Chisel Bit