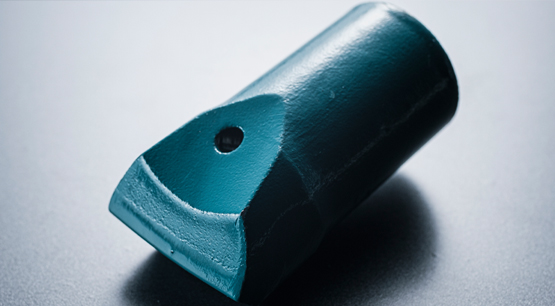

Diamond wire saw is a commonly used diamond tool in mining operations, designed for efficient cutting of large blocks of rocks or ores. In this context, we will elaborate on the operational steps and important considerations when using the diamond wire saw in mining processes.

1. Preparatory Work: Before using the diamond wire saw, thorough inspection and preparation of the equipment are essential. Ensure that the steel wire is free from any breaks or wear and is correctly installed on the cutting machine. Also, check the tension of the wire saw to match the current cutting task.

2. Site Selection: Choose the specific rock or ore area on the mining site for cutting. Prior to cutting, carefully examine the rock's structure and any existing fractures to avoid potential hazards or unstable conditions.

3. Cutting Lubrication: Continuous lubrication is crucial during the cutting process to reduce friction and temperature, which extends the tool's lifespan. Common lubricants include water and cutting oils.

4. Safety Measures: When using the diamond wire saw, operators must wear appropriate personal protective equipment, such as safety helmets, protective eyewear, earplugs, and gloves. Ensure the safety of the surrounding area and maintain a safe distance to prevent accidents.

5. Cutting Process: After starting the cutting machine, the diamond wire saw begins to cut into the rock or ore. Operators need to control the machine's speed and direction to ensure accurate and smooth cutting.

6. Progress Monitoring: Monitor the cutting progress closely during the operation. If any difficulties or challenges are encountered, stop the operation promptly and take necessary actions.

7. Completion of Cutting: Once the cutting is completed, shut down the cutting machine and conduct necessary cleaning and maintenance. Timely replacement of heavily worn diamond particles ensures efficient and high-quality cutting in subsequent tasks.

Diamond wire saws offer the advantage of high efficiency, precision, and controllability in mining operations. However, adherence to safety procedures, proper lubrication, and regular maintenance are crucial to ensure safe and stable cutting processes. Furthermore, selecting the appropriate specifications and performance of the wire saw based on the specific rock types and mining requirements can further enhance cutting efficiency and quality.