Diamond wire saw cutting technology is an advanced cutting technique primarily used for cutting hard materials such as stone and metal. Here are some key aspects of diamond wire saw cutting technology:

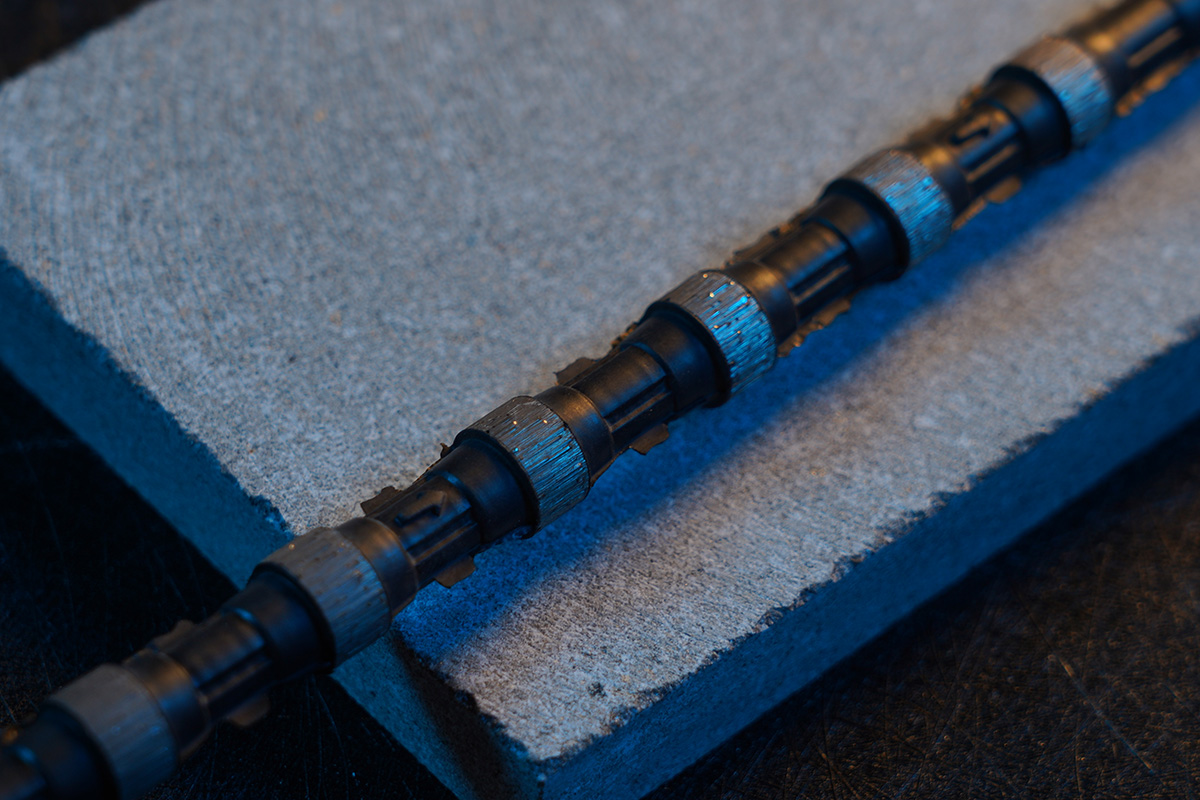

1. Diamond Particles: The cutting capability of a diamond wire saw relies on the quality and characteristics of its diamond particles. High-quality diamond particles with high hardness and wear resistance effectively cut through hard materials. Diamond particles are usually fixed onto the wire saw's steel wire through methods like electroplating, welding, or embedding.

2. Steel Wire: The steel wire used in a diamond wire saw possesses high strength and wear resistance, enabling it to withstand the saw's tension and vibrations. Typically composed of multiple strands of steel wire, it provides flexibility and bending adaptability to cater to various cutting requirements.

3. Cutting Speed and Pressure: The cutting speed and pressure of the diamond wire saw are crucial parameters that impact cutting effectiveness. Proper cutting speed and pressure facilitate efficient cutting and rapid material separation. These parameters should be determined based on the material's hardness and thickness to achieve optimal cutting results.

4. Cooling Fluid: The use of cooling fluid during the diamond wire saw cutting process is essential. Cooling fluid reduces cutting temperatures, minimizes wear and damage, and cools the cutting area to prevent overheating and material deformation. Common cooling fluids include water, mineral oil, and synthetic liquids.

5. Control System: Diamond wire saw cutting is often equipped with advanced control systems that precisely regulate cutting speed, cutting depth, and cutting path parameters. These systems enable automation, remote operation, and monitoring, enhancing cutting efficiency and safety.

6. Cutting Precision: Diamond wire saw cutting technology achieves high precision cutting, delivering accurate shapes and dimensions. By controlling cutting parameters, optimizing cutting paths, and using precision cutting equipment, high cutting accuracy can be attained.

Diamond wire saw cutting technology employs the hardness of diamond particles and the strength of the steel wire, combined with appropriate cutting parameters and cooling fluid usage, to achieve efficient, precise, and controllable cutting processes. This technique finds wide applications in stone processing, mining, construction projects, metalworking, and other industries, providing an efficient and reliable cutting solution.

Moreover, diamond wire saw cutting is considered one of the safest cutting methods among cutting tools for several reasons:

1. Remote Operation: Diamond wire saws can be operated remotely, allowing operators to work from a safe distance away from the cutting area. This reduces the risk of direct contact with the cutting zone.

2. Mechanical Cutting Principle: Diamond wire saws operate based on mechanical cutting principles. Compared to other cutting methods like flame cutting or blasting, mechanical cutting generates less heat and impact, reducing potential hazards.

3. Strong Controllability: Diamond wire saw cutting speed, depth, and trajectory can be precisely controlled, allowing operators to adjust them according to the actual situation to achieve optimal cutting results and reduce the risk of misoperation and accidents.

4. Reduced Dust and Waste Generation: Diamond wire saw cutting produces less dust and waste compared to other cutting methods, such as traditional grinding or flame cutting. This minimizes the impact of airborne dust and waste on the health of operators, improving the safety of the working environment.

5. Lower Fire and Explosion Risks: Diamond wire saw cutting does not require the use of open flames or high-temperature heat sources, reducing the risk of fire and explosions. This is particularly important when cutting flammable or explosive materials.

6. Less Noise and Vibration: Diamond wire saw cutting generally produces lower levels of noise and vibration compared to other cutting methods. This reduces the risk of hearing loss and discomfort during prolonged work.

7. Visual Cutting Process: The diamond wire saw cutting process usually offers good visualization, allowing operators to have a clear view of the cutting area, which helps avoid misoperation and accidents.

8. Easy Operation: Compared to other large cutting equipment, diamond wire saw operation is relatively simple, requiring no complex setup or adjustments. Operators only need to master basic operational skills and safety requirements to perform cutting tasks. In addition to the above reasons, the safety of diamond wire saw cutting continues to be enhanced. Improvements in safety design for cutting equipment, the addition of safety protection devices and alarm systems, and comprehensive safety monitoring and control contribute to reducing the safety risks for operators and equipment. Additionally, strengthening operator training and safety awareness ensures the safety and reliability of the cutting process.

In addition to the above reasons, the safety of diamond wire saw cutting continues to be enhanced. Improvements in safety design for cutting equipment, the addition of safety protection devices and alarm systems, and comprehensive safety monitoring and control contribute to reducing the safety risks for operators and equipment. Additionally, strengthening operator training and safety awareness ensures the safety and reliability of the cutting process.