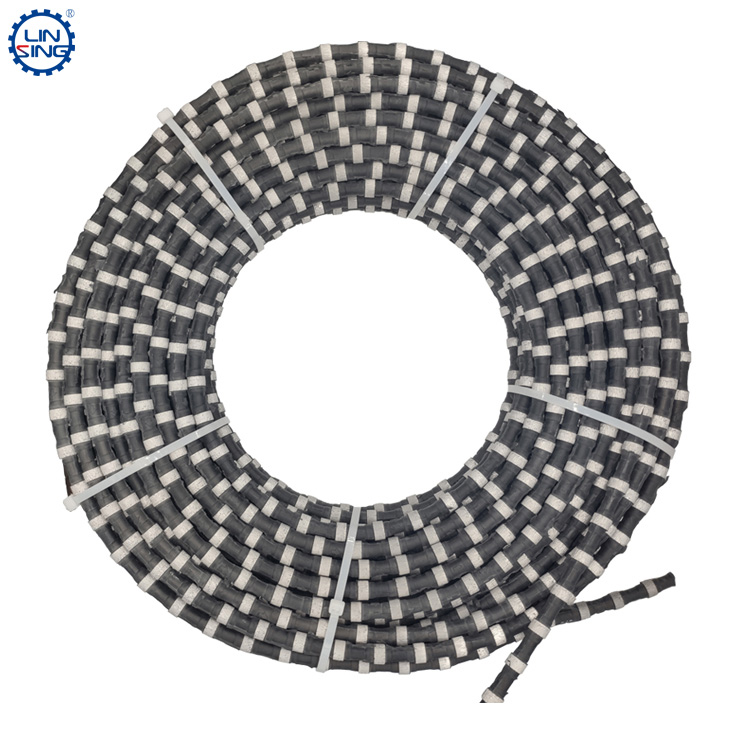

Diamond wire saw cutting is a diamond wire saw that is driven by a hydraulic motor to move around the cutting surface to grind the cutting material at high speed. Through the diamond powder in the wire saw, the cutting object is continuously ground to complete the cutting work. Due to the use of diamond, the hardest material in the world, as the cutting material, according to the laws of nature to overcome the hardness, diamond wire saw can complete the cutting of mines and concrete.

The hydraulic wire saw machine is a kind of machinery that uses a hydraulic motor to drive a flywheel. This kind of machinery is operated by a hydraulic pump and is controlled remotely by a high-pressure oil pipe. The machine is very small and easy to transport and handle. Due to the safety of the machinery, the operation is convenient and the transportation Because of its simplicity and low vibration and noise, it is slowly being used for cutting steel concrete and mining. However, because the cutting area of this kind of machinery is relatively small, most of them are used for cutting reinforced concrete structures. Columns and other frames.

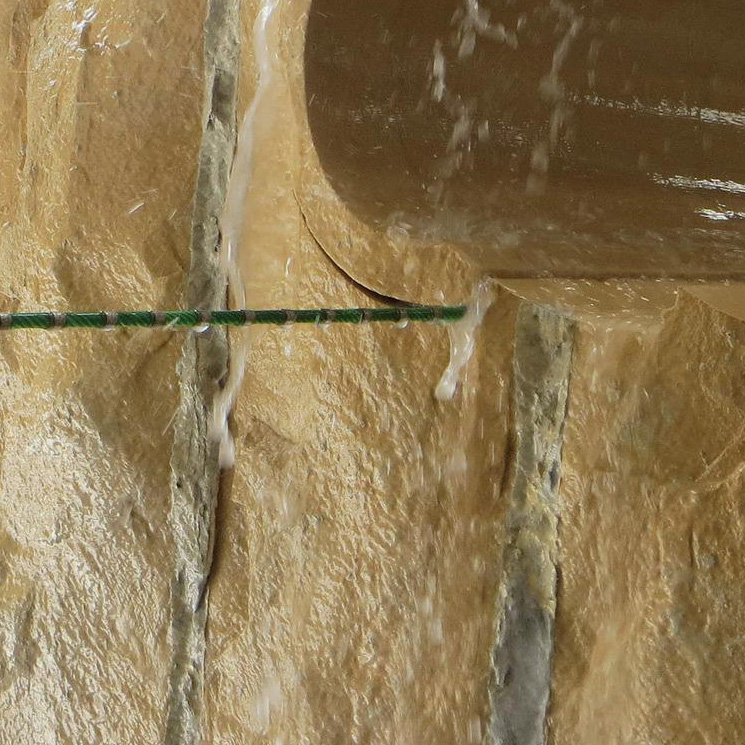

In the process of cutting concrete with hydraulic diamond wire saw, cooling water must be used. The best water flow direction is to put the water on the top of the cutting surface, so that the water can flow down the cutting groove all the way, not only can better cool the wire saw, but also It can also allow the water flow to continuously wash away the excess dust and reduce the wear of the diamond beaded rope.

Let's take a closer look at the cutting process of hydraulic diamond wire saw machine:

(1) Fix the wire saw machine and the guide wheel. Use M16 chemical anchor bolts to fix the wire saw main stand and auxiliary stand. The installation of the guide wheel must be stable, and the edge of the guide wheel must be aligned with the center line of the rope hole. In order to ensure the effective cutting speed of the cutting surface, the installation accuracy requirements are strictly implemented. The installed diamond wire saw must be rope-wound, otherwise it is easy to grind on one side.

(2) The installation rope winds the diamond rope on the driving wheel and auxiliary wheel in a certain order according to the determined cutting form. Note that the direction of the rope should be consistent with the driving direction of the driving wheel. The arrow indicates the direction is very important. Once it is reversed, wire The saw needs to be re-edged, and the direction opposite to the braided rope will also cause the wire saw to loosen the beads and crack the rubber.

(3) In terms of safety, in addition to necessary staff, cleaning up the site, and tidying up water, electricity and other facilities, it is best to set up protective fences and protective areas, and do not leave people within 25 meters of the normal wire saw cutting direction, Cutting the back side can keep people within 15 meters. Employees at the scene try to find shelters and wear safety helmets.

(4) Cutting start the electric motor, adjust the lifting tension of the driving wheel through the control panel to ensure that the diamond rope is properly tightened, supply circulating cooling water, and then start another electric motor to drive the driving wheel to drive the diamond rope to rotate and cut. During the cutting process, the stability of the machine base must be closely observed, and the deviation of the guide wheel must be adjusted at any time to ensure that the cutting rope is in the same plane. Trial operation is possible, and the operator is ready to shut down the equipment at any time. If the wire saw runs smoothly, the next step can be taken.

(5) Selection of cutting parameters. During the cutting process, adjust the cutting parameters by operating the control panel to ensure that the diamond rope runs at a linear speed of about 20m/s. On the other hand, sufficient flushing fluid should be ensured during the cutting process to ensure the Cool down and take away the ground dust. The cutting operation achieves stable speed, stable parameters and stable equipment.

(6) The problems that should be paid attention to during the cutting process, such as the occurrence of rope jamming, rope breaking, etc., should be solved by corresponding measures. The safety protection measures must be strict and rigorous, otherwise the diamond beads on the broken diamond rope will fly out like bullets and injure people. Therefore, in addition to taking necessary protective measures at the scene, all irrelevant personnel are not allowed to observe.

During the cutting process of the hydraulic wire saw, you must pay attention to the cutting sound of the wire saw, sparks and other details, the sound is too loud, or the sound is dull, you must pay attention to timely adjust the cutting speed of the wire saw, and find the cause of the problem through the stop and start changes. And for processing, the operator must not leave at will. Observe the cutting situation more to make the cutting smoother.

Cutting essentials of hydraulic diamond wire saw

Publish date:2022-07-11 16:49:56 Article From:Linxing Diamond Tools Clicks: