Diamond wire saw roping is the process of handling the diamond wire saw when the cutting or sawing process is nearing completion. If not properly guided with a positioning wheel during this period, the diamond wire saw can become excessively bent, leading to reduced lifespan and cutting efficiency, and in severe cases, wire breakage and other serious issues.

Detailed Steps for Correctly Roping the Diamond Wire Saw:

1. Preparation:

Before roping the diamond wire saw, the operators should wear appropriate personal protective equipment, such as safety helmets, goggles, and gloves.

Ensure that the work area is clean and tidy, and remove any potential obstacles or debris to prevent the wire saw from getting stuck or causing accidents.

2. Check the Diamond Wire Saw Condition:

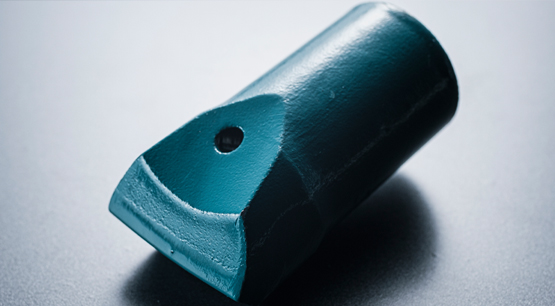

Carefully inspect the appearance and structure of the diamond wire saw, ensuring that there are no obvious damages or fatigue cracks.

Check the wear condition of the saw beads; if there is severe wear, replace the beads promptly to avoid decreased efficiency and damage.

3. Adjust the Positioning Wheel:

Ensure that the positioning wheel is correctly adjusted in terms of position and angle. The positioning wheel guides the wire saw, maintaining its stable operation.

By adjusting the positioning wheel's angle and height, ensure the smooth passage of the wire saw, preventing deviation from the cutting path.

4. Control the Roping Speed:

When the cutting or sawing process is nearing completion, rope the diamond wire saw at an appropriate speed.

Control the roping speed to be slow and steady, avoiding abrupt roping or sudden stops to prevent wire saw damage or other unexpected situations.

5. Observe the Wire Saw Condition:

During the roping process, closely observe the condition of the diamond wire saw.

If any abnormality, such as jamming or excessive bending, is noticed, stop the operation immediately and check if the wire saw is damaged or facing other issues.

6. Maintenance and Care:

Regularly maintain and care for the diamond wire saw, including cleaning its surface, lubricating critical components, and replacing severely worn saw beads.

Proper maintenance and care will extend the lifespan of the wire saw and keep it in efficient working condition.

7. Operator Training:

Provide specialized training to operators on the correct usage and precautions when handling the diamond wire saw.

Enhance the skill level and safety awareness of the operators to reduce operational errors and prevent accidents.

By following these detailed steps, the diamond wire saw can be properly roped, increasing its lifespan and cutting efficiency, and ensuring the safety and smooth progress of the mining operations.