Diamond wire saws mainly have the following seven characteristics, which determine the core reason why diamond wire saws become mainstream stone cutting materials. They are:

1.The wire saw has a large area for mining blocks.

Different from traditional mining methods, wire saws can be used to mine larger-sized stone blocks, as well as smaller-sized stone blocks, which are very difficult to achieve for other stone mining machinery and tools. Large and small blocks make the post-processing of stone more possibilities. What is particularly commendable is that this mining method can extract hundreds or even thousands of cubic meters of blocks, which greatly increases the machinability and mining efficiency of stone. This mining method is widely used in Brazil.

2.Wire saw mining can basically determine the size and shape of the block.

If the blasting method is used, the size of the blocks cannot be determined, but this mining method can carry out fixed-point and directional mining and cutting according to actual needs. The final cut blocks are both in terms of size and color. Post-cutting processing provides good processing conditions. For example, in Norway and Sweden, many mining blocks need to be beveled, and it is undoubtedly the most convenient and quickest to use a wire saw to complete such cutting. Therefore, for some stones with special cutting requirements, diamond wire saw mining will be better.

3.Wire saw cutting does not require high mechanical requirements.

If a double blade mining machine is used for cutting, this type of equipment requires rails and requires high current and voltage. For wire saw mining, diesel generators can be used to generate electricity. Under the voltage of 35-55kw, cutting will not cause much problems, and the price of double blade mining machine is very expensive, while the price of wire saw machine is relatively cheap. It is also a cost that needs to be considered in the mining process.

4.The mining efficiency has been greatly improved.

Compared with the traditional mining methods, wire saw mining greatly improves the mining efficiency. Although some rough mining methods, such as blasting mining methods, may have insufficient efficiency, the integrity of the mined stone will be better. Compared with some traditional methods of mining stone, such as rock drilling, this method will undoubtedly greatly increase the efficiency. Especially for the mining of some marbles, if the vacuum brazed beaded rope is used for mining, the mining efficiency will be greatly improved.

5.The diamond wire saw is very easy to use in the stone mining process.

Normal operators can get started after half a day of training. This is something that has never happened in other mining processes. As far as the simplest blasting work is concerned, there is a lot of experience to learn, while the wire saw only needs to know how to wear it. Rope, roping, knotting, wire saw track placement and use are sufficient. Of course, there is an understanding of the voltage, current, power, and walking speed of the wire saw machine for normal operation.

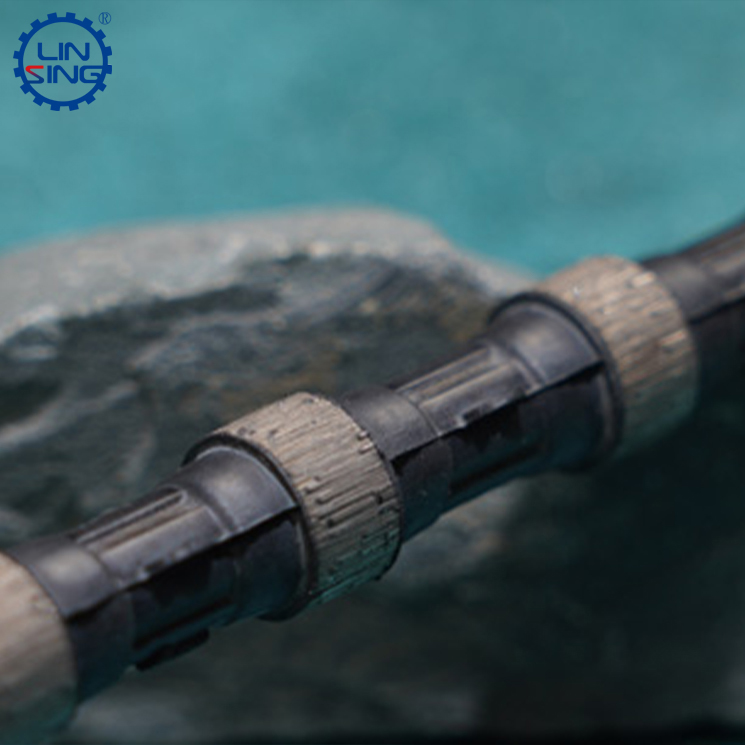

6.The cutting process of the diamond wire saw is relatively safe.

Generally speaking, in the process of wire saw cutting, if the distance is far away, there is basically no cutting risk. Generally, the safe range is within 50 meters of the wire saw cutting circumference. This is to prevent the risk of the wire saw breaking the rope and the bead falling.

7.Energy saving and environmental protection.

At present, wire saws can become a more commonly used stone mining tool. Energy saving and environmental protection are very prominent features. In terms of energy saving, the use of wire saws for mining has greatly improved the utilization rate of stone materials. Even compared with double blade mining machine cutting, the cutting seam of wire saws will narrower, which will directly reduce the waste of stone. In terms of environmental protection, it is mainly reflected in several factors such as low noise, less dust pollution, and less waste pollution. The noise is low because the wire saw does not produce particularly loud noise during the cutting process. Compared with the noise caused by other mining tools and equipment, it is within an acceptable range; in terms of dust pollution, most of the wire saw mining is water cutting, water will reduce dust pollution. Under normal circumstances, using wire saw for cutting will reduce pollution dust by 70-80%, which greatly improves the environmental pollution caused by cutting.

In terms of hazardous waste, the water flow mined by the wire saw can be recycled, and it does not generate hazardous waste itself, so the pollution of some surrounding farmlands, villages and drinking water is relatively small.