1: Overview of circular saw sawing

At present, there are mainly the following methods of mining in my country: blasting operations, flame cutting methods, expansion agent methods, etc. The mining method generally has the disadvantages of low labor productivity, low yield, serious waste of resources, and poor safety. In recent years, some enterprises have used diamond beaded wire saws and diamond chain saws for mining. Although good results have been achieved, the investment in equipment and mining costs are high, and they cannot be used on a large scale at present. How to improve the quality and efficiency of stone mining, minimize the damage to the environment, and reduce the labor intensity of workers has become an urgent problem to be solved in the mining of stone blocks in our country.  2:Cutting principle

2:Cutting principle

In response to the above situation, our country's scientific and technological personnel have cleverly applied the principle of plate cutting machines to mining, and achieved good results. The basic principle is: the track is laid on the surface of the mine, and the main engine drives a very large diamond circular saw blade (Ф2000-3500mm) to rotate at high speed to realize track cutting. Due to the advantages of less investment, high efficiency, safety, environmental protection, energy saving and low mining cost, this method is widely favored by mining enterprises.

3:Technical requirements

This mining method requires the saw machine to have good precision, and has very strict requirements on the specifications and quality of large diamond circular saw blades. As we all know, the size of the block to be mined is determined by the specification of the circular saw blade. At present, the width of the board required on the market has reached about 1.5m. Therefore, the specification of the matching diamond circular saw blade must reach Ф3500 or more. At the same time, the field operation environment such as the mine requires flatness, cooling and chip removal, etc. Compared with the plate cutting environment, the mine conditions are more severe. Therefore, more stringent requirements are put forward for the manufacture of the saw blade base.

4. Comparison of economic and technical indicators with traditional mining methods.

The application of the new mining method has improved the mining speed. Due to the improvement of the mining quality, the additional products have been increased accordingly, and the production cost has been reduced. At the same time, it has overcome the shortcomings of the traditional mining method, such as poor safety performance and serious environmental damage, and has great economic and social benefits.

5. Requirements for use

1). Preparation before installation

(1) The track laying of the saw machine requires the sleepers to be firm and flat to avoid shaking during the cutting process of the saw machine. The parallelism tolerance of the saw machine track should be ≤5mm, and the levelness tolerance should be ≤2mm.

(2) In order to ensure the flatness and strength of the saw blade cutting process, the diameter of the flange used to clamp the saw blade is >i280ram, and the unevenness of the flange directly affects the end jump of the saw blade. Therefore, the user should check the accuracy of the flange before use. Generally, the unevenness of the Ф280mm flange is less than 0.05mm, and the flange must be clean without leaving stone debris.

(3) Regularly check the accuracy of the saw machine shaft to ensure that the radial runout of the main shaft is ≤0.03mm, so as to avoid vibration during the cutting process of the saw blade and affect the cutting quality of the material during the service life of the saw blade.

(4) The size of the cooling water directly affects the cooling effect of the saw blade, the chip removal ability and the cutting life of the diamond segment. Therefore, it is recommended that the cooling water volume of Ф2000 (or Ф2200) ≥ 1001/min, and the cooling water volume of Ф2800 (or Ф3000) ≥ 1601/rnin, and fully inject it into the saw blade cutting seam. 2). Use normative

2). Use normative

Due to the high price of very large diamond circular saw blades, standardized use can greatly increase the service life of the product and reduce production costs, so standard operation should be emphasized during the use of the product.

(1) The new substrate should be idling for more than 30 minutes before the first use, so that the stress distribution of the saw blade substrate can be more uniform through the action of centrifugal force for the first time.

(2) The new saw blades of qualified enterprises should be opened before use. Otherwise, when the new diamond segment starts to be used, it is required that the amount of cutting should be ≤ l5mm/time, and the walking speed should be ≤ l000mm/min. Increase the amount of feed.

(3) During normal cutting, according to the hardness of the cutting object, the amount of feed should be reasonably determined at one time. (b2000 (or Ф2200) saw blades should be controlled within 30-50 mm/time, and Ф2800 (or Ф3000) saw blades should be controlled within 20-30 mm/time. , In order not to affect the cutting efficiency, try to achieve shallow feed and fast feed cutting process to reduce the deformation of the saw blade base due to excessive normal force.

(4) For mine cutting, when cut is lowered at both ends, the number of teeth involved in the cutting of the saw blade is greatly increased, so the resistance also increases accordingly. Therefore, the inching and reciprocating cutting method should be used when the saw blade is lowered, and the amount of the knife should not exceed 2mm per time.

(5) During the use of the saw blade, the hardness change of the cutting object should be strictly monitored during the cutting state. When the working surface protrudes too much, the cutting depth and walking speed should be adjusted in time.

Quarry cutter sawing principle and application requirements

Publish date:2022-12-05 10:38:33 Article From:LINSING diamond tools Clicks:

Diamond Wire Saw For Marble Mining&Quarrying

Diamond Wire Saw Beads

Diamond Wire Saw For Granite Quarrying

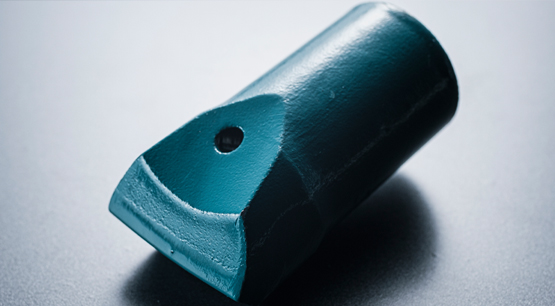

Taper Chisel Bit

Cross Chisel Bit