Diamond is divided into different grades according to different strengths and particle sizes, so what are the different points of diamond selection for these special saw blades for cutting marble? 1: Strength of diamond: strength refers specifically to the different performances of diamond in the face of impact force.

1: Strength of diamond: strength refers specifically to the different performances of diamond in the face of impact force.

The higher the strength, the diamond will not be broken when the saw blade faces the same impact force. Conversely, the weaker the strength, the more broken the diamond is. Then it seems that the stronger the diamond, the better the cutting ability. In fact, it is not.

The choice of diamond strength depends on the hardness of the stone. If the hardness of the stone is soft, choose high-strength diamond as the raw material of the cutting tool. During the cutting process of stone, high-strength diamond will behave very normally at the beginning, but as the marble continues to consume the diamond cutting edge, the diamond edge will be rounded. At this time, due to the fixed cutting depth, the current will be too large and the cutting resistance will increase during the cutting process. At this time, reducing the line speed is an inevitable choice. As the linear speed decreases, the high-strength diamond has no sign of breaking under the impact force of the stone, and the rounded diamonds will cause the saw blade to cut the stone completely, because all diamonds have this kind of phenomenon. The situation where the rounding diamond cannot be consumed and cannot be cut.

On the contrary, if the hardness of the stone is high and the diamond with weaker strength is selected, then the diamond will appear in a state of rapid consumption. Due to the rapid wear of diamonds, diamond segments are worn out very quickly. Although the cutting efficiency is maintained to a certain extent, a large number of diamonds are quickly broken in the process of friction with the hard rock, and the diamonds that still have cutting ability are wasted in vain, and the life of the diamond segment is extremely short.

Under normal circumstances, the choice is to cut the stone with higher hardness, and it will be better to use diamond with higher strength. For cutting medium-hard stone, match with medium-hard diamond. For cutting soft stones, it is more suitable to use a low-strength diamond.

2: In terms of particle size: 2-3 different diamond particle sizes are generally required in the marble cutting process.

In the process of rough cutting, large-grained diamonds can form large tails, and large-grained diamonds are of great help for stone sawing work. However, when the diamond with large particles is broken, the consumption is also the largest. Because large particles of diamond tend to be separated by large particles, the utilization rate will be greatly reduced. In order to maintain the utilization rate of large-grained diamonds, part of the medium-large- or medium-grained diamond powder is often added for mixing. Other particles with large particle size can share the impact force of large particles, which also alleviates the severe crushing of large particle size diamonds.

The granularity of marble determines the efficiency of marble cutting. The use of large particles can increase the cutting gap of the diamond segemnt and increase the cutting capacity. If the medium-grained or fine-grained particles are used for cutting, the cutting efficiency is greatly reduced because the diamond with small particle size has a small cutting surface and few edges. However, in terms of life, it can be improved to a certain extent, so the diamond particle size determines the sharpness and life of the marble saw blade. Appropriate adjustment of this parameter can achieve a good cutting effect.

3: Diamond concentration: the diamond concentration is also called the diamond distribution density, the volume of diamond in the diamond segment per unit volume.

Simply put, the higher the concentration, the higher the diamond content. In the process of cutting marble, the diamond segment with a concentration of 50-75% has excellent cutting performance. Below this value or above this value, the difference in the performance of the diamond segment is very large. For example, if the concentration is too low, the life and sharpness will be greatly reduced; if the concentration is too high, the life will be slowly increased, but the sharpness will be greatly reduced. In general: generally coarse-grained diamonds are used for cutting soft marbles, while smaller grains are used for cutting hard marbles. The higher the diamond concentration, the more the number of grains on the surface of the diamond saw blade, which is beneficial to improve the life of the diamond segment. However, as the concentration increases, the sharpness of the saw blade presents a parabolic state of up and down.

In general: generally coarse-grained diamonds are used for cutting soft marbles, while smaller grains are used for cutting hard marbles. The higher the diamond concentration, the more the number of grains on the surface of the diamond saw blade, which is beneficial to improve the life of the diamond segment. However, as the concentration increases, the sharpness of the saw blade presents a parabolic state of up and down.

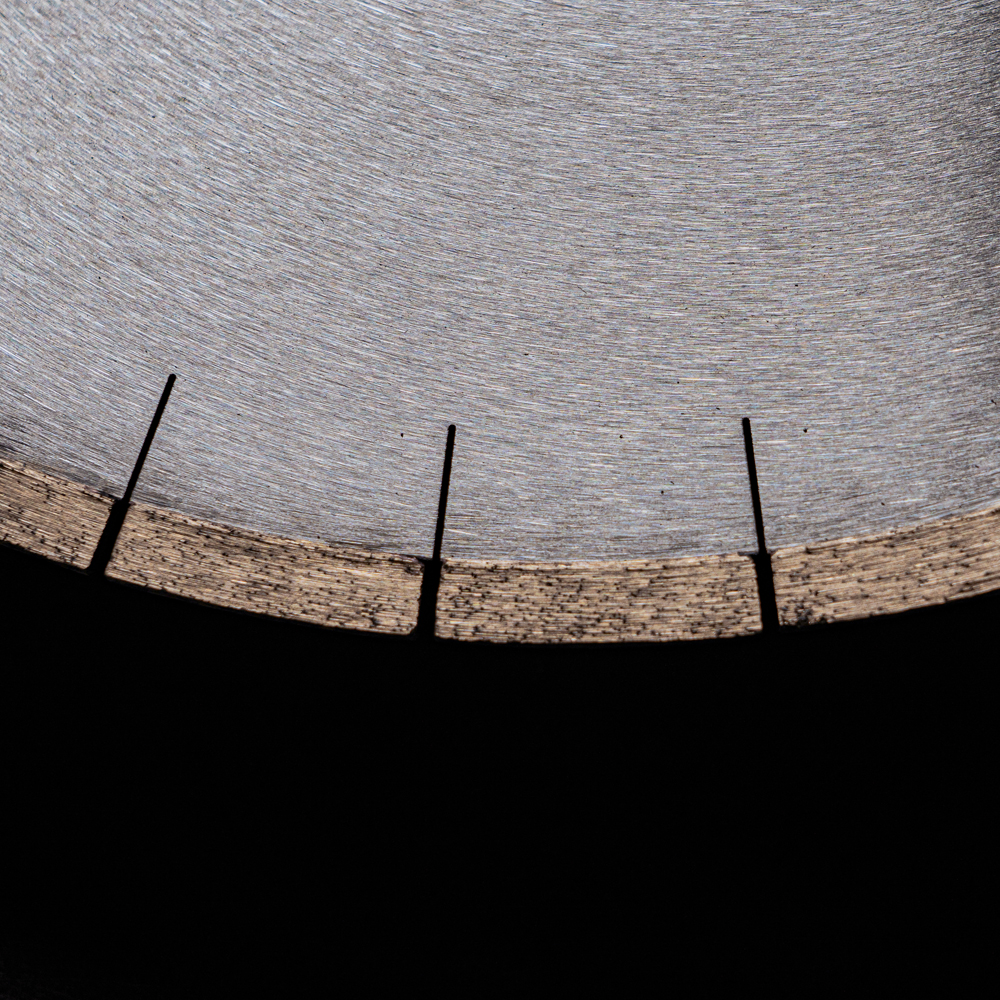

Diamonds in marble saw blades

Publish date:2022-12-05 09:36:14 Article From:LINSING diamond tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

- Top 10 Mistakes in the Diamond Segments Selection Process

- Why The Diamond Segments Have Been Processed Into Vavious Shape?

- What should do if the segment is moved grinding during the cutting process?