Diamond wire saw (referred to as wire saw) is the use of special technology, such as electroplating, brazing, sintering and other methods to solidify synthetic diamond particles on the metal substrate to make diamond string beads, and then the string beads on the wire, through special equipment and molds for injection, injection (or with springs and rings) fixed, creating a strip of flexible diamond cutting tools.

Diamond wire saw cutting before the end of the wire saw with a connection head to connect the ends of the wire saw into a closed ring, and then driven by a motor or hydraulic motor-driven wire saw machine and tension, around the cut object for high-speed rotational motion, while applying a certain amount of pressure to the cut object, fast-running wire saw string beads constantly grinding the cut, to fixed in the string diamond as the main cutting material, and finally completed the cutting of hard material. At present, diamond wire saw is widely used in mining, waste shaping, stone special-shaped processing, stone cutting into plates, as well as the demolition of steel mixed buildings, according to different application scenarios, the use of wire saw types are not the same. This article analyzes wire saws produced in three of the most common different processing methods:

Electroplated beaded wire saw

Electroplating wire saw is electroplating method of diamond plating fixed to the bead substrate, the benefits of this process is very obvious, the entire electroplating process does not need to be heated to complete the fixation of diamond powder, only the electroplating liquid constantly form a new diamond coating, so that diamond intact fixed in the plating layer. Since all the diamonds of this product are exposed to the outside of the wire saw, during the cutting process, the diamond layer of the diamond wire saw is mostly involved in the cutting process, so the efficiency of cutting will be greatly improved. However, the disadvantages of this product are also very obvious, because diamond is distributed on the bead surface, diamond will be consumed quickly, thus greatly shortening the life of cutting. In terms of price, the price of the plating process is much higher than the price of sintered beads.

Vacuum Brazed bead wire saw

Brazing string beads is a vacuum brazing method, diamond powder fixed on the bead substrate of a process, and electroplating products similar, however, because the process used in this product is more environmentally friendly, will not be because of the larger pollution of electroplating liquid environmental protection eliminated, at present, electroplating products due to water pollution is larger, in a phased process, but brazing as a less polluted process, worry-free access to more people. The beads of the brazing process compare sintered beads, the efficiency improvement is very large, in order to improve the life of brazing beads, it is found that the brazing beads into double-layer will greatly improve its sharpness, so at present, most of the brazing beads are double-layer structure.

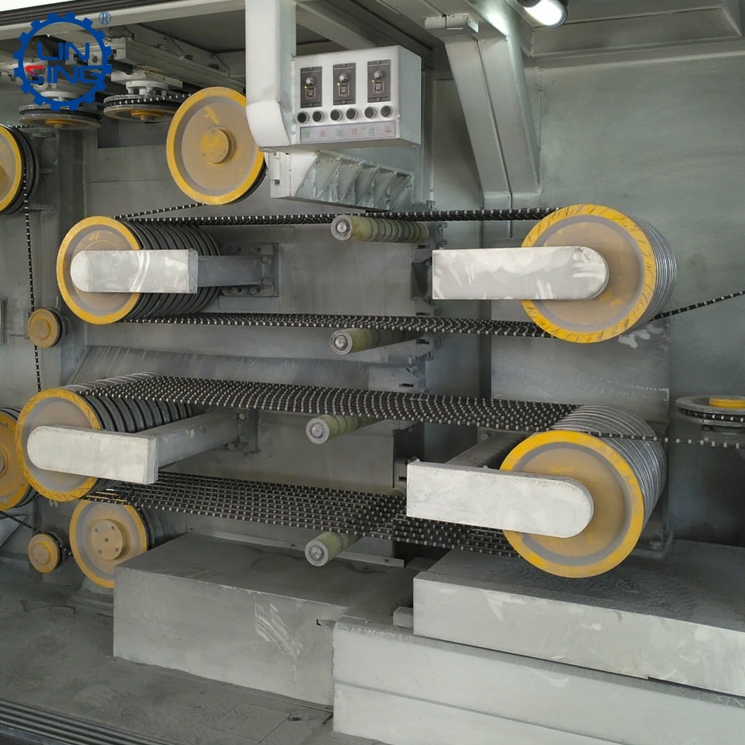

Sintered beaded wire saw

Sintered beads are diamond powder mixed with metal powder, and then sintered on the bead base, this structure of beads, diamond distribution is more uniform, the upper and lower layers can be cut, so the life of this product is very long, in terms of cutting capacity, this high wear resistance, can cut granite and other stone materials, and brazing and electroplating products due to consumption too fast, life is too short caused by high costs, is currently used in marble mining.