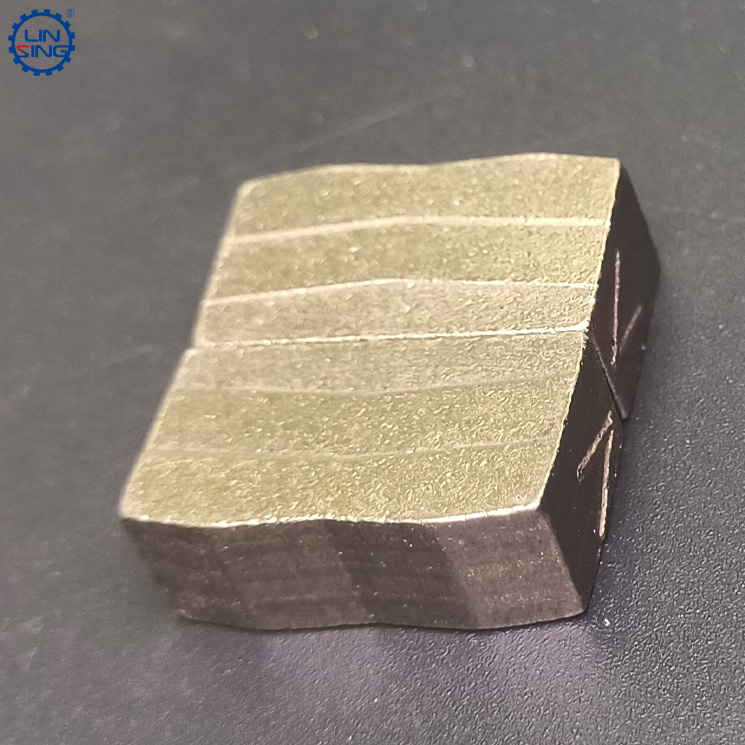

The layers segment is a new type of diamond segment that uses the working layer and the non-working layer to be arranged in a cross cycle. Because this segment contains multiple non-working layers, the non-working layer does not participate in cutting, so the metal bond and diamond are reduced in disguise. The amount of powder used reduces manufacturing costs. In addition, during the use of this segment, there is no significant reduction in life, and because the non-working layer is added, this non-working layer quickly forms a concave gap when processing the stone, which makes the segment better. Cooling also facilitates chip removal. What is more important is to make the working layer protrude. During the cutting process, the protruding part of the working layer better exposes the diamond, which also allows the segment to have better sharpness.

Therefore, the layers segment can not only reduce the material cost, but also increase the cutting efficiency in disguise. Such a product that kills two birds with one stone naturally received good feedback from customers. Slowly, this type of layers segment is slowly being accepted by people. Currently layers There are two types of segments. The first type is a segment made of metal powder as the non-working layer, and the second type is a segment made of iron sheets. The following describes the characteristics of these two layers.

The metal powder is the diamond segment of the non-working layer. Because the intermediate layer is powder, this segment is easily combined with the working layer during the sintering process to form a very strong whole with relatively stable performance. Therefore, such a segment The service life is higher than that of the segment with iron sheet as the barrier. There are two shortcomings of this segment: First, the cost is higher, because although the metal powder in the middle lacks diamond powder, the rare metal is still needed in the formula, so the cost is increased. Second, the non-working layer is prone to formula differences, which need to be adjusted continuously, which increases the work of the designer and improves the design difficulty. Because the working layer and the non-working layer of the segment must be closely integrated, there must be great differences between the two Similarity, such as similar metal heat-resistant properties and similar expansion coefficient, otherwise it is very prone to cracking during segment cutting.

The iron sheet is the diamond segment of the non-working layer. The middle of this segment is a fixed iron sheet. The material is very cheap, so the cost is extremely cheap. Among all the segments currently on the market, the iron sheet interlayer segment is the lowest in price. However, the shortcomings are also very obvious. There are three main points: First, the iron sheet is difficult to combine with the working layer. During the cutting process, the iron sheet and the working layer may separate, which will cause the segment to fall off. Second, the iron sheet is easy to rust. If the cutting time is too long, the iron sheet will naturally rust. Although surface treatment can be performed, it will still cause unstable segment performance. Third, although the price of iron sheet is cheap, there are not many thicknesses to choose from, and there are many restrictions on the design formula.

Linxing diamond tools has developed and designed layers diamond segment, which has the advantages of stable performance, high processing efficiency, and low price. At present, Linxing layers segment is sold to many countries and regions all over the world and is deeply trusted by customers. In particular, Linxing's iron layers segment has done a lot of tests and research on the holding power of diamond powder and iron pieces and the rust prevention of iron pieces. At present, it has developed very stable layers segment products with both performance and life. Better than other segment products.