In the process of diamond saw blade cutting, especially when cutting stone, it is easy to have the problem of segment falling. Below, we will introduce the reasons that can cause the diamond segment to fall.

1: Insufficient welding causes the segment to fall: At present, most diamond saw blade manufacturers use high-frequency welding, but some manufacturers use high temperature to heat the segment and bond, and then fix the segment in this way On the bond, this method does not fix the segment very firmly, so it will cause the segment to fall off. During the welding process, the segment is not correct and the height is uneven, which will cause the segment to fall.

2: Choose a poor silver weld holder. During the process of segment and bond welding, a silver weld holder needs to be added in between. If the quality of the selection is poor, it will not play the role of connecting the segment and the bond, and naturally it will cause the segment to fall off. Generally, if it is the problem of the silver weld holder, the segments will drop in batches.

3: Too fast cutting speed, too fast mechanical cutting speed, the sharpness of the segment is very high, if the sharpness of the segment is not reached, it is very easy to cause the segment on the saw blade to fall.

4: Too fast speed or running speed, when the saw blade is cutting hard stone mechanically, when it just start cutting, if the speed is too fast, it will produce extremely strong impact force, if the speed or running speed is particularly large, It is very easy to cause the segment to fall off.

5: The cutting material does not meet the requirements. The saw blade for cutting marble should not cut granite, and the saw blade for cutting soft stone should not cut hard stone. If it is used indiscriminately, the segment will fall.

6: Insufficient water intake or lack of cooling water, a very important reason for segment falling is that the segment temperature is too high during the cutting process, thereby reducing the stability of the segment structure.

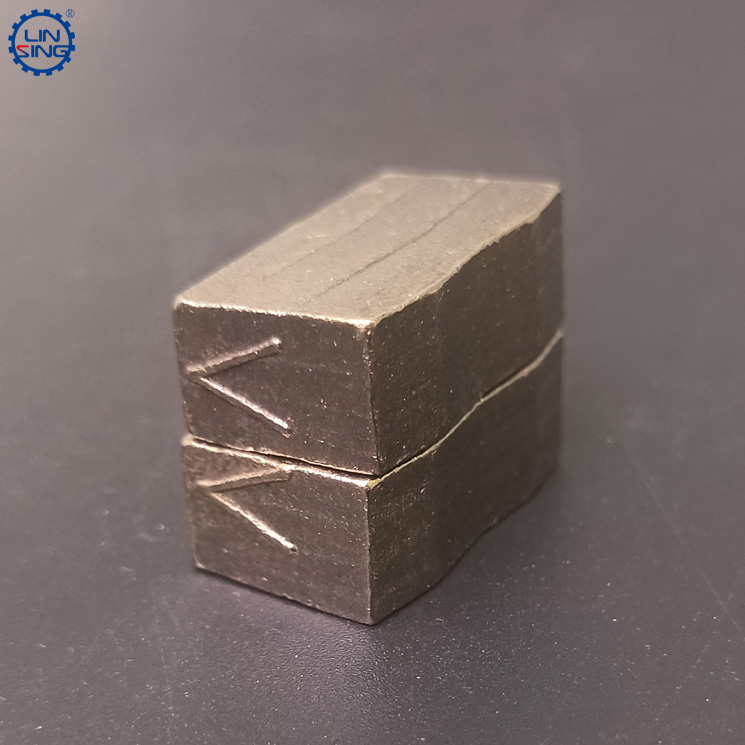

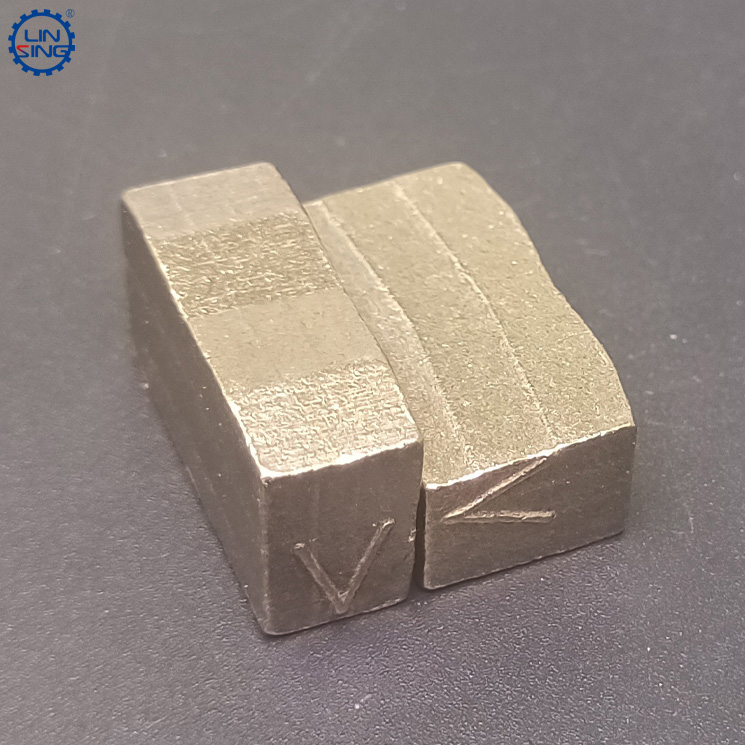

7: Segment quality problems cause the segment to fall off. For example, the segment sintering temperature is not enough or too high, the heat preservation time is not enough, there is a problem with the segment formula, the segment bond is too soft, and the mixing process is uneven.

8: Insufficient segment sharpness causes the segment to fall off. This problem is very common. Especially for new formulas, it is normal that the sharpness is not enough. Generally, in this case, reduce the rotation speed or the knife speed.

9: Segment sizes are different. In the segment production process, many manufacturers use the mold multiple times to cause deformation during the segment production process. Such different sizes will make the protruding part of the segment very vulnerable to impact. Underneath, it naturally causes the segment to fall.

10: There are many other factors, such as the segment is left for too long, which leads to segment oxidation. For example, segment arcing is insufficient, resulting in all impact forces acting on the segment junctions. For example, if the bond of a diamond circular saw blade is too hard and the toughness is insufficient, it can also cause the segment to fall.

Although there are various reasons for the diamond segment drop on the diamond saw blade, the solution is not complicated. In summary, there are three solutions:

1. During the welding process, be sure to follow the normal welding process, and try to ensure the welding strength, and make the segment completely symmetrical.

2. In terms of segment, choose a regular diamond segment manufacturer, and try to let the manufacturer give different segment specifications for cutting different stones. If cutting a variety of stones, try to choose a segment product with strong versatility.

3. During the cutting process, adjust the mechanical cutting data. For the new segment formula, it must be slow first and then fast, while observing and adjusting to prevent the segment from falling off.

Reasons and solutions for diamond saw blade falling segments

Publish date:2022-07-06 17:39:46 Article From:Linsing Diamond Tools Clicks:

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- Hot pressing sintering technology of diamond segment

- What should do if the segment is moved grinding during the cutting process?

- Sintering process of Linxing diamond segments

- Important notice! 2020 Xiamen International Stone Exhibition will be postponed to October 27-30!