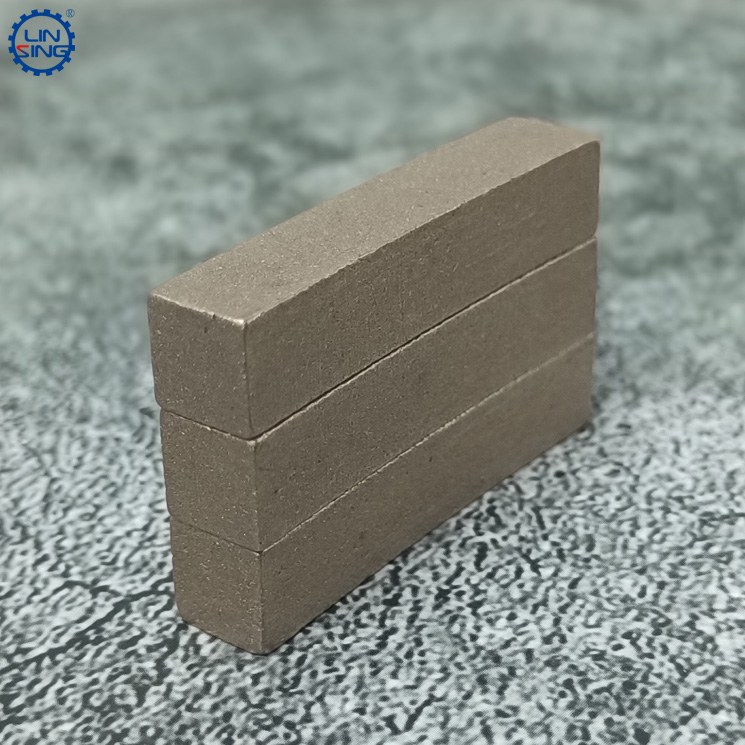

The diamond segments are divided into layer structure, which can be divided into non-interlayer diamond segments, sandwich diamond segments and multilayer diamond segments. The non-interlayer diamond segment is formed by cold pressing and sintering, after then form into diamond agglomerates. The sandwich diamond segments is a non-working layer with metal powder in the middle, and in the cutting process, it will forme the convex on both sides and concave in the middle. The biggest feature of this segments is that there is only a non-working layer in the middle. Its name also explains the shape and principle of its cutting process. The interlayer segments is actually a diamond segment with multiple interlayers, and the total number of layers is often an odd number of layers. Strictly speaking, sandwich segments are also a kind of interlayer segment, but the middle compartment is larger, which is different from ordinary interlayer segments.

Let’s talk about the non-layer diamond segments. Most of the earliest diamond segments were without layer. However, due to the characteristics of high cost, low cutting efficiency, high requirements on formula and technology, the earliest segments were gradually replaced by the layer segments. Of course, the segments without layer have great advantages in stability and life, so at present, there are still many stone cutting machines or saw blades that still use non layer segments.

The gang saw segments is still designed without layer, because the gang saw adopts a push-pull processing method. If used the segments with layer , it is not easy have chip removal problems, and it is more likely to have segments with tail worn problems, while the middle part cann’t reach to cut, and most of the gang saws are used to cut marble, and the abrasiveness of marble is higher than that of granite, so the segments without interlayer is more suitable.

Most of the segments for medium-diameter saw blades and small saw blades are without interlayers. The medium-diameter saw blades are small in size and thickness is thinner. If the interlayer is forcibly added, not only will it not save too much diamond, but also it will cause the production process more complicated and the performance of the segments is unstable. For small disc less than 300MM diameter, the integrated segments will save more production costs.

In terms of large saw blades, if you are cutting abrasive marble and limestone, it is more cost-effective to choose a segment without layer. As for the cutting of granite and sandstone, it depends on the customer's focus, sharpness or life. The interlayer segment focuses on sharpness, while the segment without interlayer focuses on life.

Multilayer segments are rarely used on saw blades with a diameter of less than 600mm, but saw blades higher than 600 mm will be required by customers. Generally speaking, the more layer, the better the sharpness, but the life will be decrease relatively; and the more less interlayers, the better in the life, but the sharpness improvement is not obvious. Therefore, at present, in combined saw blades, there will be more interlayer segments, and single-blade saws will choose more non-interlayer segments with longer life. In application of mining, the layer segment is better than those without layer.

As for the sandwich diamond segments, the scope of usage is extremely limited, and only some markets have applications. Although this segments reduces the production cost greatly, and with high efficience, but relatively short in life. At present, most common applications are used in cutting marble block.

Application of non-interlayer and multilayer diamond segments

Publish date:2022-07-06 17:50:50 Article From:Linsing Diamond Tools Clicks: