Q: what kinds of diamond circular saw blades are there?

Answer: there are many types of diamond circular saw blades. The current mainstream method is to distinguish circular saw blades from different metal bond, base materials and production processes. Usually, they can be divided into cold-pressed sintered blades, electroplated saw Blades, vacuum brazed saw blades, hot-pressed sintered high-frequency welded saw blades and hot-pressed sintered laser-welded saw blades. It can also be distinguished by size. Large saw blades with a diameter of more than 900 mm, medium diameter saw blades with a diameter of 250-850 mm and small cutting disc with the diameter of 230mm and below.

Q: how is the diamond embedded into the saw blade?

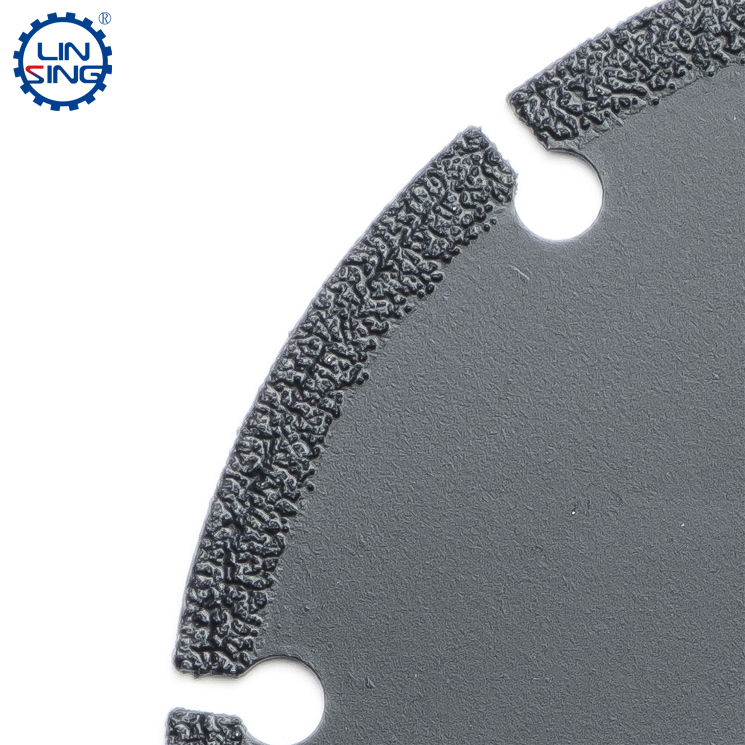

Answer: before answering this question, we must first understand a question: what is a “material layer”. The material layer is also called the cutting layer of a circular saw blade. At present, the material layer of electroplated saw blades and brazed saw blades is distributed on the saw blade blank surface. And such products of diamond segments like cold-pressed or hot-pressed sintered diamond segments are welded on the saw blade. the height of diamond segment is the material layer. At present, the thickness of the material layer is more reasonable, and the lifespan can be guaranteed.

All in all, the material layer of the electroplated saw blade or the vaccumed brazed saw blade is to make the diamond inlaid on the surface of the substrate by electroplating or brazing. The welding saw blade with diamond segments are to insert the diamond into the diamond segment by cold pressing or hot pressing, and finally the saw blade and the diamond segments are integrated by welding.

Q: what is the best speed of diamond saw blade when it is working?

Answer: due to the different sizes of saw blades, only the line speed can be used as the speed measurement standard. According to our practical experience, when a worker cuts stone with a hand-held machine, the linear speed of the saw blade should be 1200-1500 m/min. In fact, the line speed setting of diamond circular saw blades is not simple. Different saw blade diameters, different blade sharpness, different saw blade materials and different processing machinery will affect the line speed of the saw blade. But in the sawing process, the faster the speed is not the better. Because each diamond saw blade has the limits of critical speed and mechanical properties. Too high or too low speed of diamond saw blade can not give full play to its performance.

Q: some saw blades will vibrate during the cutting process after using for a period of time. What causes this? How to eliminate and prevent such situations from happening?

Answer: the saw blade vibrates in two directions, one is to swing in the axial direction, that is, the top of the saw blade vibrates left and right (referred to as end vibration), and the other is radial jump. This type of condition is when the saw blade bounces back and forth (referred to as radial vibration). If it is an end vibration, it is often caused by the unevenness of the saw blade. The saw blade needs to be removed for leveling. If it is radial vibration, it is possible that the spindle of the cutting machine is bent, so the spindle needs to be repaired. Another reason for the radical vibration is that the spindle shaft and the inner hole of the saw blade are not aligned. In this case, it is necessary to loosen the flange that fastens the saw blade, so that the saw blade can move and rotate, and then adjust in order that the saw blade hole is center the flange, and finally tighten it.

The radial vibration is easy to make the saw blade misaligned, and the misaligned saw blade is difficult to repair. Therefore, once it is found that the saw blade has a radial vibration, it is necessary to stop the cutting work immediately to repair and adjust the machine or saw blade in time.

Q: the material layer has not been used up, why is the cutting efficiency significantly reduced?

Answer: there are several situations that can lead to this problem. The main reason is that the diamond distribution is uneven. There are many upper fabric layers and less lower fabrics, so this situation occurs. In addition, there are another two situations: the diamond concentration in the middle layer is not enough. Or the diamonds in the upper layer are consumed, but the diamonds in the lower layer have not been exposed. Under the circumstance, the solution is to re-open the diamond segments by cutting the refractory brick or grinding the material layer with a grinding wheel.

Secondly, there is a problem with the middle edge material. The middle edge material layer of the saw blade is high in the middle and low on both sides. During the cutting process of the diamond segments, if there is no cutting space, it will also lead to the situation that the cutting does not move. The solution also needs to adjust the diamond segments. Re-opening will solve the problem.

Q: What is the best coolant to use?

Answer: it is better to use a mixture of one kilogram of saponified oil oil per hundred kilograms of water as the coolant.