In nature, granite has different components according to its color, and these different components also determine the hardness and abrasiveness of the stone, and these different stones require different segment attributes. This article mainly By introducing the current 300-1000mm saw blade segment produced by Linxing Diamond Tools, let everyone understand the styles of different segments and their cutting characteristics.

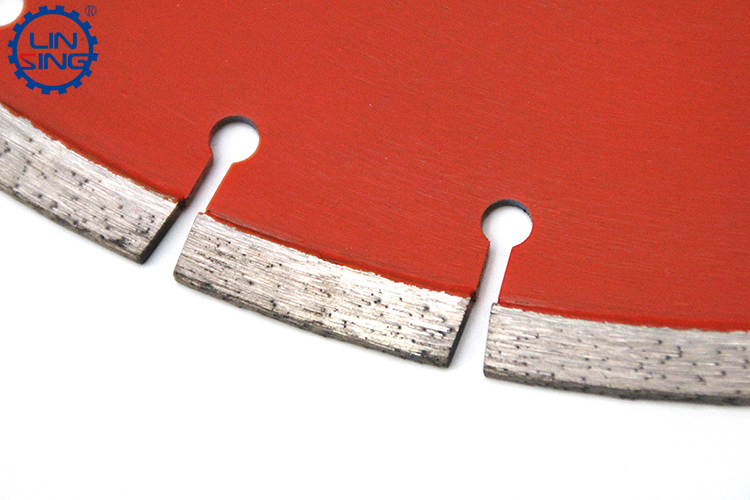

The 300-1000mm saw blade segment is the cutting teeth on the diamond saw blade with the saw blade diameter of 300-600mm, which is mainly used for edge cutting of stone slabs, curb stones, tombstones and other stones. The diamond segment is fixed on the saw blade base by high-frequency welding or laser welding, so we want to talk about the style of the diamond segment. First, we need to consider the style of the base. Currently commonly used substrates are designed according to edge openings, which are mainly divided into keyholes, U-shaped holes, and fish hook holes. These pores mainly take into account drainage, chip removal and edge collapse. Generally, U-shaped holes and keyholes are commonly used in granite. The design of the keyhole is for better chip removal, while the U-shaped groove is mostly used for silencers, and the large U-shaped groove can also be used for chip removal. These two designs are common designs for 300-1000mm saw blades, fish hook holes The saw blades are mostly used for cutting marble and ceramic tiles, so I won’t go into details in this article.

R-shaped segment, this kind of segment is the most common, presents a fan-shaped shape, the inner arc and outer arc are consistent with the base arc of the saw blade. The advantage of this kind of saw blade is that the sharpness is average, the life is average, and it is very traditional. The height of 10, 15, 20mm is optional, the higher the segment has the higher the life, but considering that the segment will have partial wear or side wear, 15mm segment is more cost-effective.

V-groove segment is to open a V-groove in the middle of the segment. This saw blade is suitable for softer granite, which can increase the stability of cutting edge, reduce chipping, and improve the stability of grinding, but it will reduce the life of the segment. .

Short-tooth segment, compared to the common 40mm long segment, the short-tooth segment is designed to have a length of 20 cm. It is welded to a characteristic short-length segment or two segments are welded side by side on a saw tooth. The advantage of this segment is that it has more stable cutting performance, and the segment welding strength is increased, which reduces the risk of tooth loss.

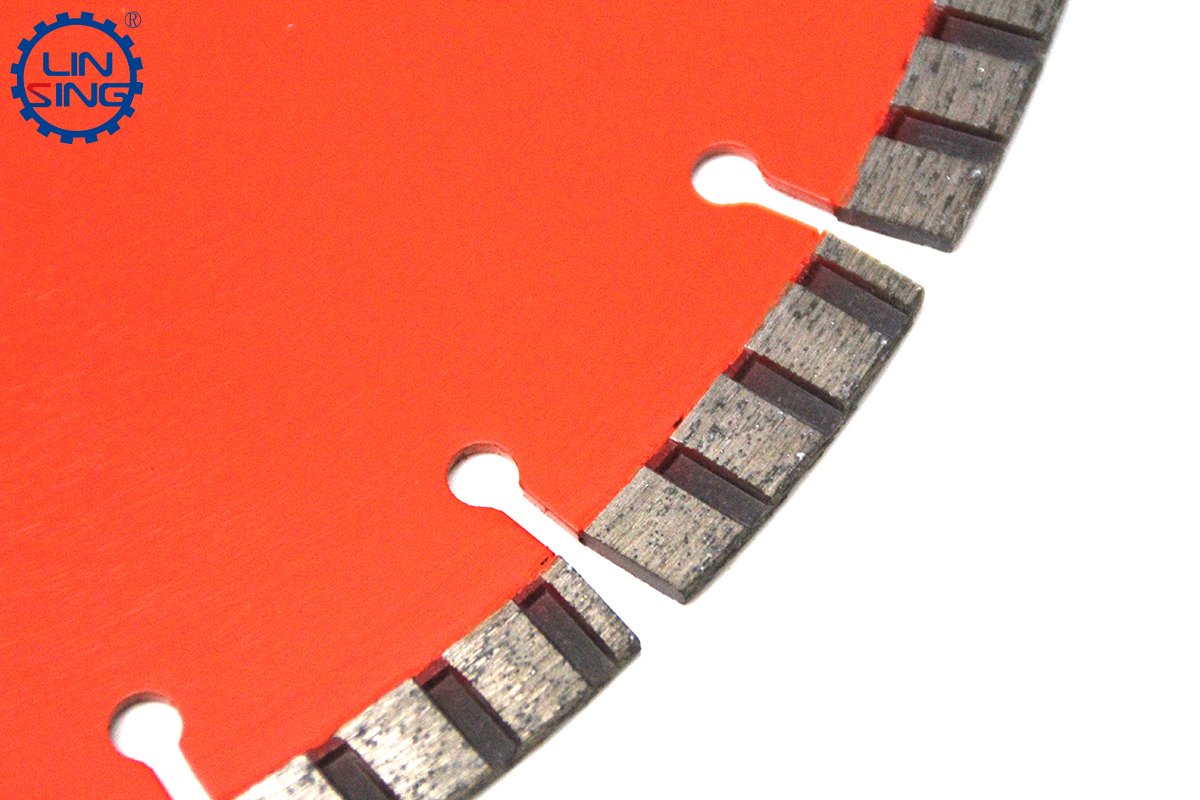

Corrugated segment, corrugated segment is a relatively special segment, this segment uses corrugated teeth for cutting, so in the cutting process, the force area of the cutting teeth is reduced, and the pressure is increased when the pressure is constant. Let the segment cut faster and cut more stable, in terms of cooling, corrugated segment has a great advantage.

Ordered segment, ordered segment is a newer stone cutting segment, ordered segment is R shape, but in terms of segment design, one side of ordered segment is straight edge, one side is slanted edge, and the whole segment appears to be oriented Slot road cut before. Because this segment uses a fixed place to discharge the diamond, the diamond can be fully utilized, so the cutting efficiency and life are 30% higher than the ordinary saw blade, but the disadvantages are also obvious, and the price is higher.

There are many types of saw blade segments. For example, T-shaped teeth are used to reinforce the segment on the front and back sides of the segment to make the segment smoother during the cutting process and prevent knife jams. There are also U-shaped segments, M-shaped segments, W-shaped segments, etc., but these segments have fewer uses, and most of their purposes are to increase cutting efficiency and improve cutting stability. For many years, Linxing Diamond Tools has produced various styles of segments, matched with the saw blade substrate, and worked hard to provide stone customers with cost-effective products.