With the development of the diamond industry, at present, diamond segment products are constantly innovating with the development of technology. At present, the products are gradually stable, but Linxing Diamond Tools is still moving towards cutting segments faster and longer. Directional development, in the case of limited revolutionary promotion, changing the shape of the segment has become a good choice for improving segment performance. Currently, the large granite segments manufactured by Linxing mainly have the following four shapes:

M type segment

The M-shaped diamond segment is to make the cutting surface of the segment into an M shape. The specific shape of the segment is a flat bottom and an M shape on the top. The two protruding cutting teeth on the surface quickly complete the edge when cutting the stone. This kind of segment also eliminates the cumbersome process of cutting the segment before, and by changing the shape, it reduces the process of segment processing stone and reduces production costs. M-type segment is currently Linxing's best-selling product. In the continuous application process, the life span and cutting efficiency of M-type segment are continuously increased, and this product has gradually gained customer recognition.

K-segment

The K-shaped diamond segment is a K-shaped diamond segment with high sides on both sides and low in the middle. The original intention of this segment design is that the cutting edge of the circular saw is extremely troublesome when the customer is mining the stone, and the cutting edge will also be disguised. To reduce the service life of the segment, how to make the segment better sharpen the edge on the circular saw, the K-type segment can easily solve the problem of sharpening: during the cutting process, the side of the K-type segment quickly collides with the stone and rubs Because of the small contact area and strong pressure, the K-segment is easily ground out of diamonds on the side, and then the diamond on the side will slowly drive the segment on the other side to sharpen the edge. Finally, the diamond segment is obtained. Very good cutting edge results. At present, Linxing Diamond Tools's K-segment is mostly used in mining circular saws, but if there is a very poor abrasive stone, the block cuts this kind of stone, the K-shaped stone also has an excellent edge effect.

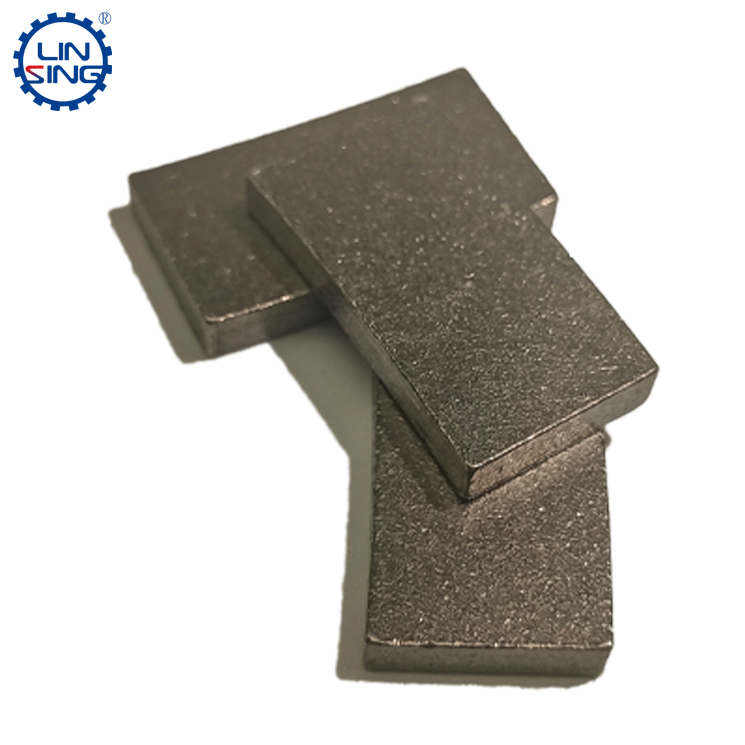

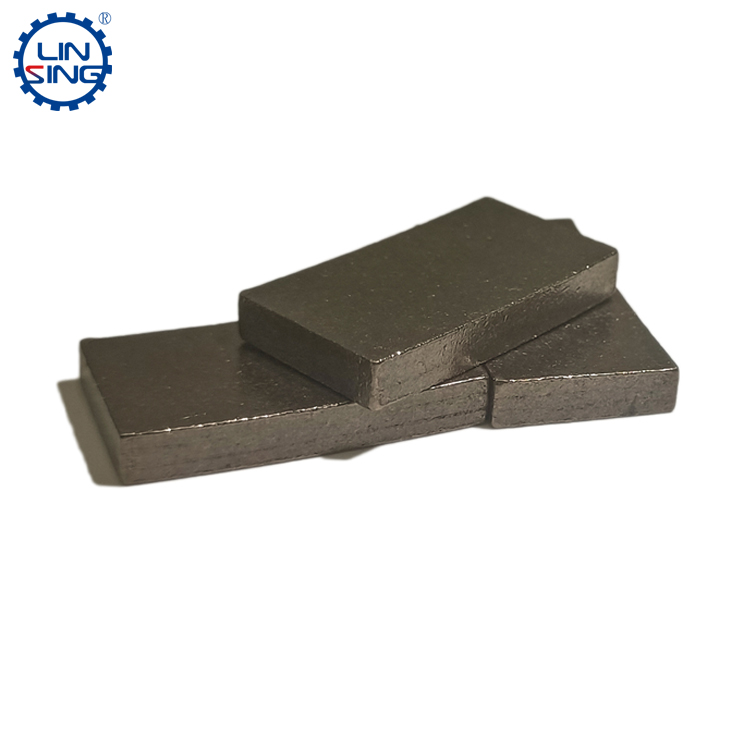

Square segment

This type of segment uses the simplest mold, which is a segment designed and manufactured using a rectangular parallelepiped mold. This segment does not have any cutting edges. This is the earliest segment shape commonly used by people. The advantage of this segment is very obvious, that is, it has a long life. , Poor sharpness, suitable for cutting medium-hard to soft granite. The shortcomings are also obvious, that is, it is not easy to open the edge, the cutting efficiency is slow, and the cutting of super-hard stone will not move.

Arc segment

This segment is an arcuate arc in the cutting part. During the cutting process, the arcuate arc slowly wears out. By reducing the cutting area and increasing the pressure, the edge is sharpened. This segment also has excellent edge sharpening. However, the disadvantage is that due to the continuous changes in the arrangement order and grinding angle of the diamonds in the arcuate segment, the diamonds are easily damaged by impact, so although the effect of cutting edge is good, the processing life is greatly shortened.

The diamond segments of the above four shapes can be used for granite processing, but there are also many differences in details and actual processing. The specific situation can be customized according to the materials processed by itself.

Several common shapes of granite large segments

Publish date:2022-07-07 08:51:18 Article From:Linsing Diamond Tools Clicks: