The segment for cutting granite is one of the most common diamond tool products. It is fixed on the saw blade by welding. During the processing of the stone, the diamond segment continuously rubs against the stone through the rapid mechanical speed. Under the action of force, the diamond in the segment completes the grinding of the stone with its extremely high hardness.

Since stone has different cutting requirements from mining to finally becoming a part of home decoration, the segment also changes with the role of the saw blade. This article mainly uses several common types of granite segment to make everyone more Good knowledge and understanding of granite segment and the demand of granite cutting for segment.

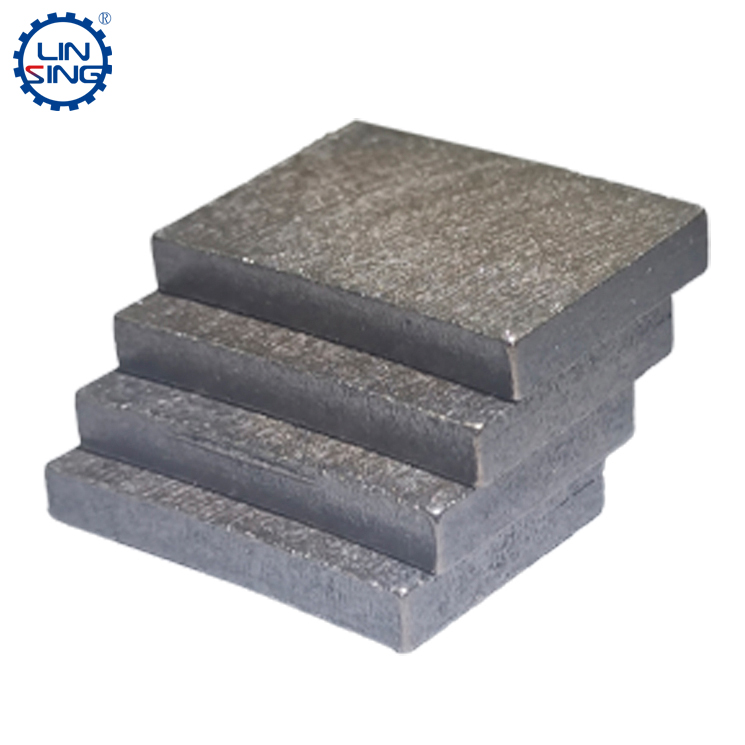

Mine segment is the first scene involved in granite segment. In China, there are rich granite mineral resources, especially flat mines and mountain foot mines, which are rich in mineral resources. After the working face is flattened by wire sawing, the mine forms a huge and flat working face. At present, a large number of mining work will use a circular saw for processing on a working surface of several thousand square meters or even tens of thousands of square meters. The circular saw generally adopts a double-blade design. There is a saw blade on the left and right sides, and the saw blades on both sides Weld the mine segment, then lay the track vertically and horizontally, and then the circular saw will follow the track to complete the mining process of the mine. The final result is that the mine forms blocks of the same size and specifications, and the sides are flush with the cutting effect. Finally, a wire saw is used to separate the bottom of the block from the mine, which is also called the bottom. In this mining process, the mining segment plays a great role. One is to separate the blocks from the side of the mine. The second is to standardize the blocks so that the final block specifications tend to be consistent. Third, Saving stone resources, fourthly, eliminating the need for trimming the later blocks.

Multi segment and single segment. After the granite is mined, it will be transported to the stone processing plant in the form of blocks. The stone processing plant will perform secondary processing of these blocks. There are two main types of the first, which are processed into large slabs. It is completed with a mounted saw blade, which is divided into single, three, five, seven and nine bridge multi-machines or eight, twelve, fourteen, sixteen, eighteen, Twenty-two single-arm multi machines are used for processing. In order to improve efficiency, more multi-machines are becoming more popular. The mounted saw blade of the bridge multi machine increases its diameter from small to large, and the single-arm multi uses two different specifications. The common saw blade combinations are six large and six small, eight large and eight small, and eleven large. Eleven hours and so on, but no matter how it changes, the width of the multi machine segment is fixed. The second type, cut into special-shaped stone, is irregular stone (such as tombstones, such as monuments, such as large sculptures, etc.). At this time, you need to use gantry cutting, or it can be a multi machine with a single saw blade. The size of the saw blade segment and the diameter of the base body of the similar machinery often vary, and different single-blade saw segments need to be selected for different diameters.

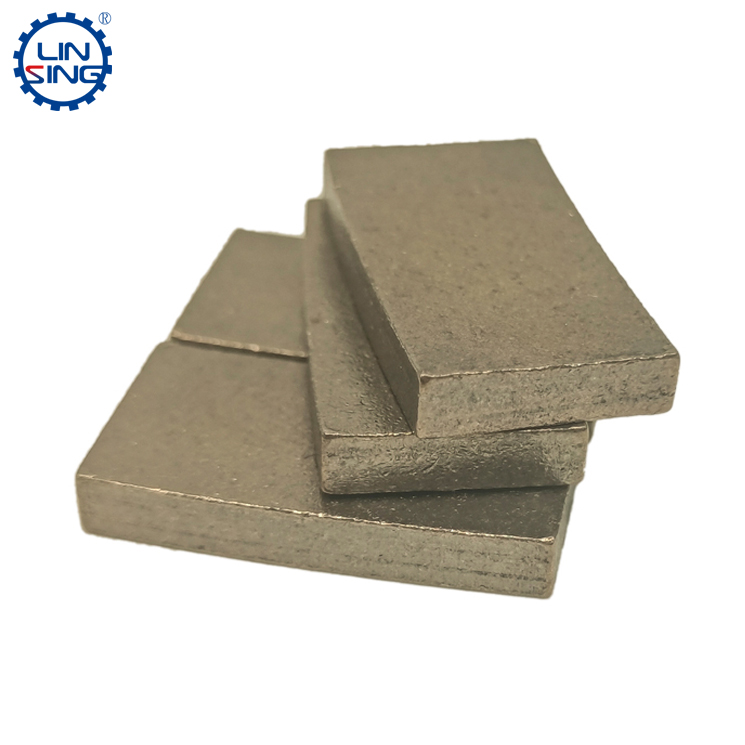

For the stone that is cut into slabs or small blocks, you need to cut the large slabs into specification boards or cut the cut small materials into smaller blocks. At this time, you will choose a mid-diameter saw blade, the diameter specification is from 300-850mm, among which The 300-450mm blade is mostly used for plate cutting, while the 500-850mm saw blade is mostly used for the middle cutter. If the block is larger, the maximum diameter can reach 1600mm according to the requirements. Pitch saw blades are often welded with pitch saw blade segments. The biggest difference from mining segments and block cutting segments is that the length of the segment becomes longer, the width decreases, and the height decreases.

There are gang saw segments, bucket saw segments, trimming segments and so on for cutting granite. Their functions are different, but because of the small amount, this article will not introduce them in detail. Friends who are interested can pay attention to us, and we will discuss this later. One type of segment is introduced separately and in detail.

granite segment types

Publish date:2022-07-07 10:27:29 Article From:Linxing Diamond Tools Clicks: