Diamond segment of the original raw material is a powder state, to powder objects into a block-type solid, mold is essential, the normal process of processing the segment, in fact, is the use of mold molding segment style process, this paper is mainly for the diamond segment from powder to finished two molds, as well as different uses.

Early diamond segments in the production process, only one graphite abrasive, powder filled into the abrasive, through fastener compression, let diamonds and powders send the internal air, and make each other closer, but in the sintering process, with the temperature "The liquid metal reacts physically and chemically with the metal, the pores between the powders are filled, the segment size begins to shrink, and the liquid metal becomes fluid as a result of the extrusion of the mold, and when cooled, the size of the segment becomes uneven." There may even be significant differences in the width or height of the segment, making it more difficult to produce the segment.

In order to avoid this situation, people began to design a cold press, cold press using steel film pressing way, the specific way is to fill the powder into the steel mold, through high pressure, the powder-like metal pressed into pieces, this process is also known as chipping, its core principle is to use different steel film to turn the segment powder into a solid state, convenient later sintering. The difference between steel film is that different segment sizes require different specifications of steel film for slicing, especially multi-layer structure or sandwich structure of the segment, steel film size needs to be customized very precise.

Cold-pressed steel film is best made of high-grade alloy steel, such materials made of alloy steel in terms of service life or accuracy are higher than ordinary steel structure.

After cold pressure, the segment size will not be too different, but in terms of weight there will be some errors, the current Linxing diamond segment cold pressure process allows error of 0.05%, if the error is too large, the powder needs to be re-cut, and then secondary pressing.

After cold pressure, the segment is convenient for later filling into graphite abrasives, and reduces the dust situation of the factory, reduces pollution, and plays an important role.

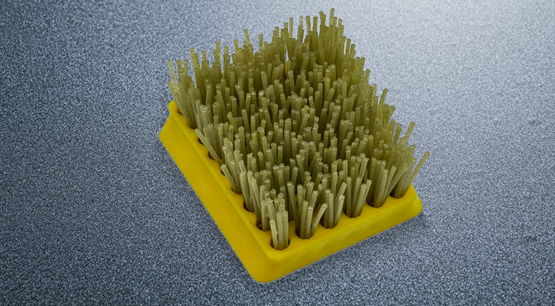

The second mold is the graphite abrasive required in the process of hot-press sintering, the graphite abrasive is made of steel outside and the inside is a graphite block. Graphite mold with positive and negative poles, power-on state, high resistance graphite due to electricity to produce a large amount of heat, when the temperature at 600-800 degrees Celsius, cold pressure after the metal powder plate began to melt, melted metal through full physical and chemical reactions, after late cooling, will eventually become a tight clump segment product.

The second mold is the graphite abrasive required in the process of hot-press sintering, the graphite abrasive is made of steel outside and the inside is a graphite block.

Graphite mold with positive and negative poles, power-on state, high resistance graphite due to electricity to produce a large amount of heat, when the temperature at 600-800 degrees Celsius, cold pressure after the metal powder plate began to melt, melted metal through full physical and chemical reactions, after late cooling, will eventually become a tight clump segment product.