The mining cutter is a diamond cutter used for mining. This cutter is welded on a large circular saw blade. It is divided into marble mining cutters and granite mining cutters for different mineral sources. Mining segments are currently not widely used in marble mines. The main reason is that the structure of marble is relatively soft. Wire saw mining can mine larger stones and sell for higher prices. Therefore, wire saw mining of marble is still the mainstream. For granite, mining segments are widely used. The same specifications and smooth cutting surface ensure the integrity and uniformity of the stone. It can also save time and effort in the later processing and reduce the trimming process.

In the process of mining granite, there are many points that need to be paid attention to:

1: Large blade for small saw blades: Mining saws currently use double-blade saw blades. First, small-sized saw blades are used for cutting. It is worth noting that although small-sized saw blades have a small diameter, they need to be used. A thicker blade. The reason for this is that in the cutting process of a small saw blade, with a certain mechanical power, the speed and traction of the saw blade are stronger, which can help the saw blade to cut the gap quickly, and the large gap can facilitate the use of large saw blades later. Make a cut.

2: The large saw blade uses a small segment: in the mining process, after the small saw blade is used for grooving, the large saw blade needs to be used to complete the deeper cutting. If the cut stone is of high value, the small saw blade can be used first , And then use a medium size saw blade, and finally use a large saw blade to complete the cutting. As the size of the saw blade increases, the width of the segment will decrease. The advantage of this is to ensure that the cutting seam will not be blocked due to too much debris. , And the stone powder is used for the second grinding of the segment, or it may cause the grinding of the matrix.

3: The mining segment must be given a large amount of cooling water during the use process. A sufficient amount of cooling water can quickly wash the stone powder, and it can also cool the segment to make the segment cutting more stable. Once the amount of water is not enough, the stone powder will cause multiple grinding processes and reduce the service life of the mining cutter. However, the amount of cooling water should not be too much, because too much cooling water will cause the segment to slip during the cutting process, resulting in the problem of not moving the stone. A reasonable amount of water should be just enough to wash away the stone powder, and the stone powder in the cutting groove is washed away, but there is no large amount of water.

4: The waterway of the segment in the mine is especially important. The segment of the mine should use a wide and thick iron sheet as a multi-layer structure. The larger the water path, the faster the sharpness of the segment. Similarly, the cooling effect of the segment during the cutting process And chip removal effect will be better.

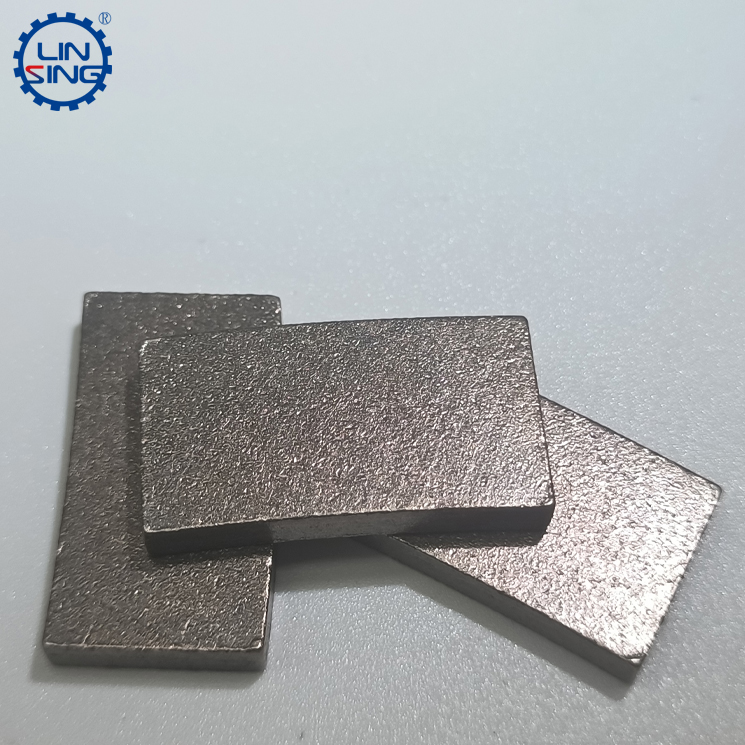

5: At present, there are two main shapes of mine diamond segments that are more popular. The first type is M type segment. This type of segment is more common and will have advantages in terms of cutting edge. The second type is K type segment. Although this kind of segment is easy to sharpen, but in the cutting process, the front end is easily damaged or deformed by impact, so it is gradually used less, but if cutting medium soft granite, this kind of segment has more advantages in cutting edge efficiency.

6: The thickness of the segment of the mine is a trapezoid shape with a wide top and a narrow bottom. This approach is also to protect the saw blade substrate from grinding, and it can also allow the cooling water to cool the blade better.