The copper-based segment is a diamond segment made using a large amount of copper powder as raw material. The abrasiveness of the copper-based segment is weaker than that of the iron-based segment, so many times, people use copper-based segments to cut softer stones, such as marble and limestone. , Travertine and other materials.

There are many types of copper powder. Among them, brass and bronze are more common. In the actual sintering process, bronze powder is more common, because bronze powder is an alloy powder made of tin and copper through sintering, while brass powder is made of zinc. And copper powder formed by sintering. If brass powder is used as the main raw material, the zinc element in the brass will undergo drastic chemical changes during the sintering process. Due to the active zinc element, various chemical reactions will occur in the diamond segment, which will lead to the segmentation. Performance is unstable. The opposite is true for bronze powder. The chemical properties of tin are very inactive and will hardly be oxidized in the air. At high temperatures, tin will quickly melt and form a very dense metal alloy with other metals. Under normal sintering conditions , Bronze-based segment will have stronger stability and better life performance.

Can the bronze-based diamond segment be welded? This is a very simple question. In fact, all metal segments (that is, diamond segments) can be welded, nothing more than the difference in the required welding materials. So what kind of solder is used for the bronze-based diamond segment?

Because the bronze-based segment contains a large amount of tin and copper elements, ordinary brazing sheets cannot be welded. The specific reason is that during the melting of the brazing sheet at high temperature, it quickly forms bronze with the tin elements in the segment. , And the bronze material structure is not strong enough, and the copper element in the segment and the brazing sheet begin to be welded together, but because the two elements are the same, no chemical reaction can occur, so the welding strength is extremely limited, and sometimes the welding temperature is too low Or in the case of improper operation, there will be no welding at all.

Bronze-based segment welding can be welded with silver-copper solder plates with a silver content of more than 35 percent. The tin powder and silver elements in the bronze base melt quickly to form a low-temperature solder silver-tin alloy. This solder is suitable for copper elements. The bronze-based segment contains a lot of copper elements, so under normal circumstances, the segment will be quickly welded to the diamond saw blade substrate, and the molten solder will quickly form a solidified alloy agglomerate. The intensity is extremely high. However, due to the fact that the silver solder tabs are not resistant to high temperatures, this welding method is suitable for wet cutting, not dry cutting. Otherwise, after dry cutting, the rapidly rising high temperature will cause the solder tabs and the financialization of the joint, which will cause the segment to fall off. , Prone to safety accidents.

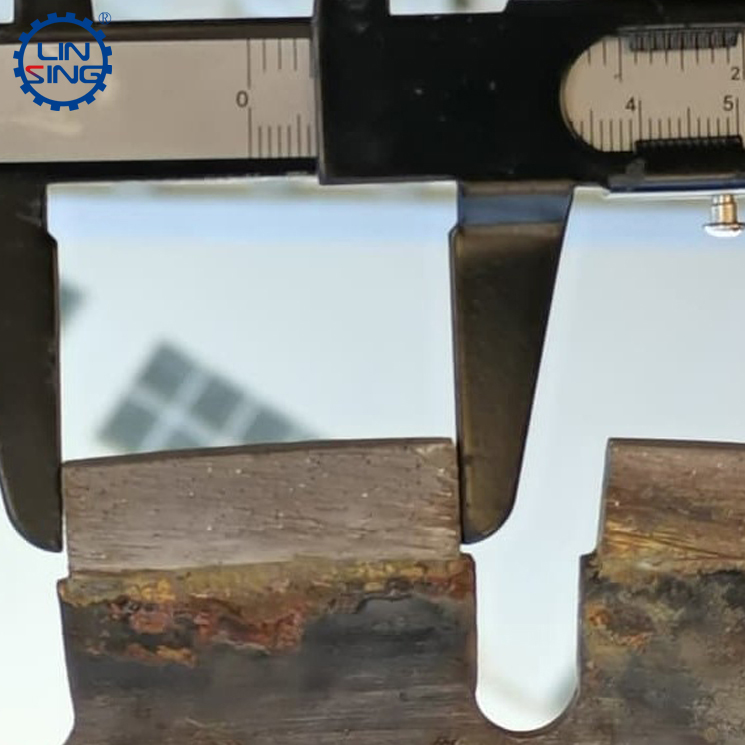

In general, the bronze-based diamond segment is prone to insufficiency in the welding process. After the welding is completed, the fixing strength of the segment needs to be checked with pliers. Once it becomes loose, it needs to be welded again.