The production process of diamond segment is very complicated. Mastering the core technology will obviously improve the product quality and its stability. Therefore, the core production technology is very important. So what production technology is there for diamond segment production? There are mainly the following:

Powder ratio technology: Powder ratio technology is the biggest problem faced by diamond segment manufacturers. There are thousands of stones in the world. Different stones have different cutting hardness, density and abrasiveness, plus different machines in different countries. , Different usage habits, these factors will cause a lot of changes in the diamond segment. In the early days, every manufacturer bought back the formula at a high price, and the big diamond segment manufacturers tried their best to prevent the theft of the segment formula. For this reason, they are willing to invest a lot of money in confidentiality, and this habit has been continuing. But later people found that a single formula cannot meet the needs of the market and customers. People have their own needs for products, especially for foreign foreign trade markets. A single powder formula will only fall into a situation of rapid elimination, so more, better The demand for formulas is also generated, so how should small segment manufacturers deal with it?

There is a market when there is demand. Soon, various metal powder manufacturers slowly appeared on the market. For small segment manufacturers, these powder plants provide mixed metal powder materials, and the ratio will be customized according to different customer needs , And these manufacturers who have mastered the powder ratio are gradually growing, and the powder ratio technology on the market is also concentrated in these powder factories.

But for fast-growing companies, powder formulation is the core competitiveness. Linxing diamond tools has focused on training R&D personnel since its establishment in 2003. At present, the company has thousands of powder formulations and is constantly updating products to make products better adapted. market.

Sintering temperature and pressure control technology: The sintering temperature directly affects the quality of the product. If the temperature is too high, the excessively carbonized diamond cannot exert its cutting ability and consumes quickly, thereby increasing the cutting cost. However, if the temperature is too low, the chemical reaction between the metal powders is not sufficient, which will result in insufficient segment strength. When the impact force is too large, the segment is prone to deformation and falling off.

The sintering pressure directly determines the density of the segment. If the sintering pressure is too high, the segment is prone to liquid retention, and there will be large errors in the shape and size of the segment. However, if the pressure is not enough during the sintering process, the segment powder will Insufficient density and too loose segments occur, resulting in poor segment quality and low control over diamonds.

Diamond segment detection technology: The diamond segment detection technology is divided into two types. The first is the detection of raw materials, powder composition, thickness and quality of the iron sheet, diamond size, shape, particle and other aspects. There is also a finished product inspection. The best way is to perform actual cutting. Of course, a grinding wheel can also be used to inspect the life and wear resistance.

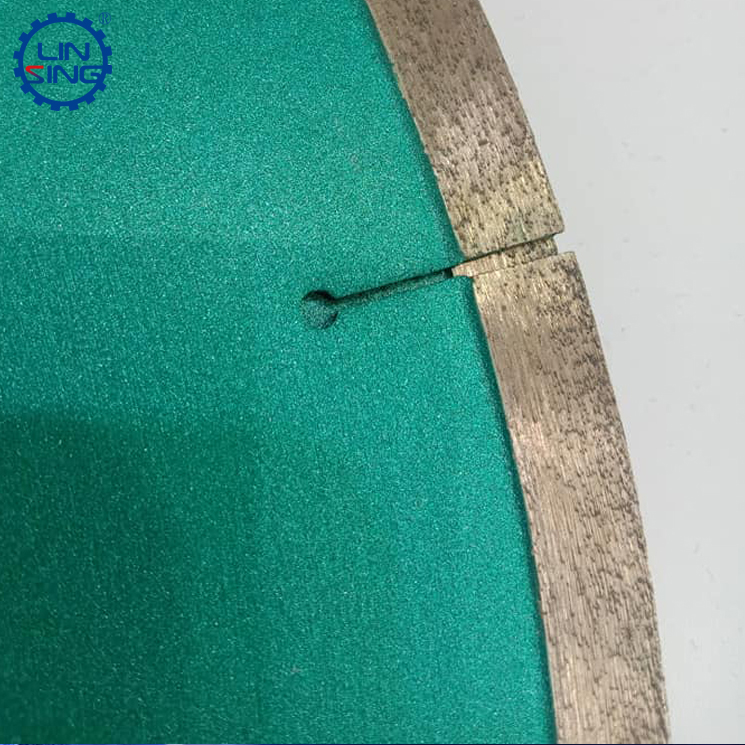

Diamond segment production technology

Publish date:2022-07-12 17:26:48 Article From:Linsing Diamond Tools Clicks: