The main reason for the arcing of diamond segment cutting is that the saw blade oscines horizontally during the cutting process, resulting in the wear and tear of the movement of the stone on both sides of the stone. In general, the lateral swing of the blade is related to the following factors:

(1) The blade base is swing. The segment is welded on the blade, when the blade base is out of shape, then there will be cutting arcing situation easily, at this time, replacing the base is the best choice.

(2) Blade base’s stiffness. Base stiffness is a kind of tenacity of the blade base. When the stiffness is not enough, the blade in the cutting process will be bent due to the role of radial force. So that the blade is affected by lateral force. This usually occurs in cases of poor substation quality.

(3) The segment welding asymmetry, that is, the diamond of the segments explore are not same, resulting in saw blade swing by the role of lateral force.

(4) Poor precision of equipment, stone machinery in the process of cutting stone, if the equipment is not good enough, beams or spindle are too light, in the cutting process saw blade in constant vibration, cutting accuracy will be worse, lateral swing will also appear.

(5) Saw blade speed. The higher the speed, the greater the vibration will be brought, such vibration will make the knife cut stone when the situation of arcing.

(6) High hardness of stone. High hardness, strong abrasive stone in the cutting process, easy to cut the situation, so the vibration is very easy appeared. The best solution of this situation is diamond communicate with the segment manufacturers clearly in advance, to custom super hard stone special diamond segment.

(7) Block placements is uneven, will directly lead to horizontal grinding. If this happens, the bottom trimming of the block can be carried out in advance using tri-edge machinery.

If there appear segment arcing situation, we must be comprehensive analysis of the problem, find out the problem, and then solve. Some arcing problems cannot be solved, such as mechanical problems caused by the not cut and grinding, it is best to always have a leveling machine, secondary processing.

The main reason for the arcing of diamond segments

Publish date:2022-07-06 09:14:42 Article From:Linsing Diamond Tools Clicks:

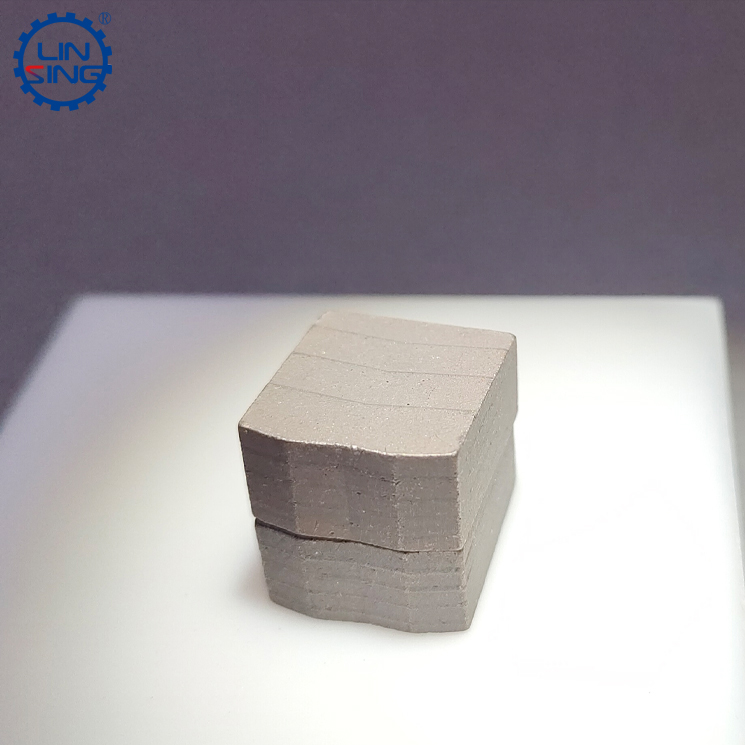

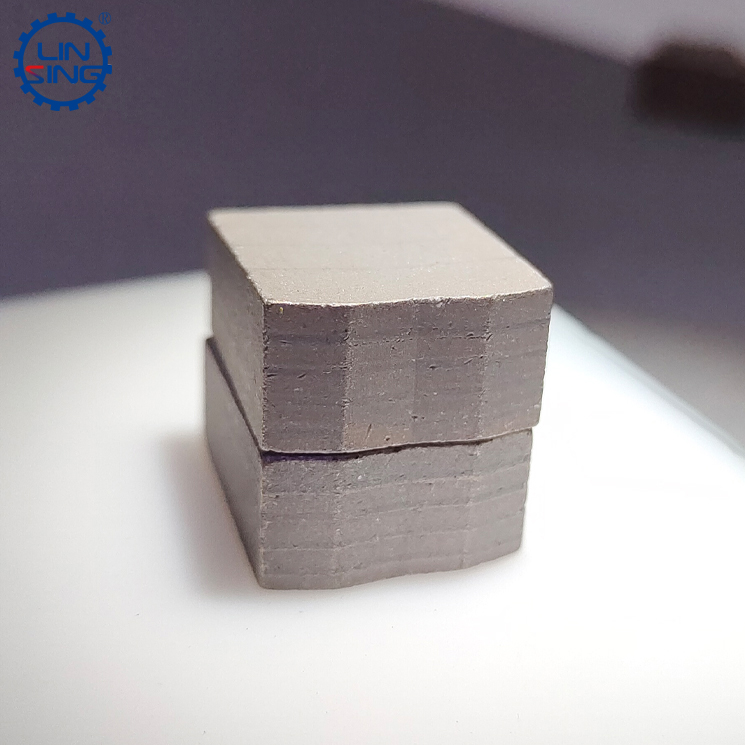

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades