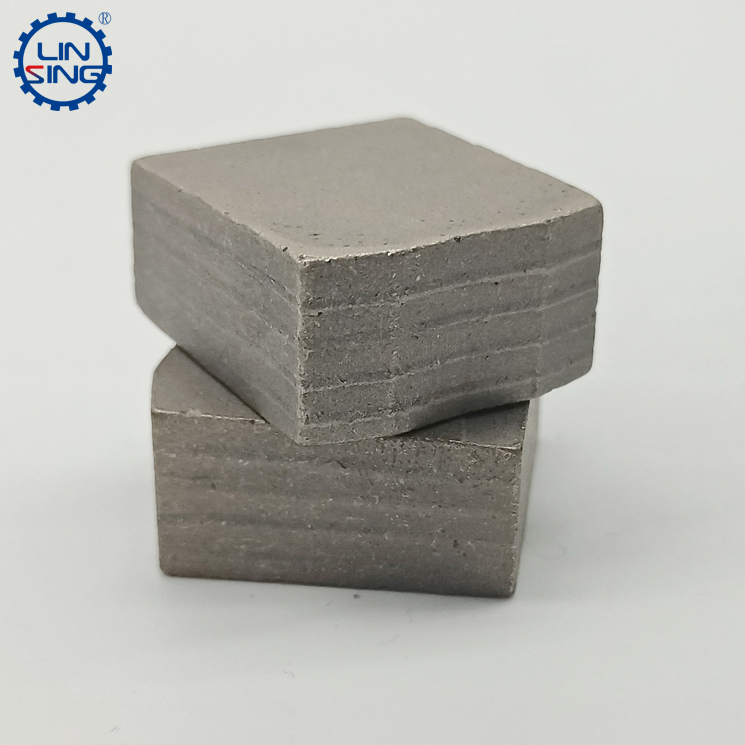

The diamond segment is a combination of diamond and metal bond. Diamond is well understood. At present, most of them are made of artificial diamond powder. When making segments, there are grades of diamond powder for different stones and different formulations. According to the hardness, it can be divided into super hard, hard, and medium hard. . This differentiation of hardness allows diamond segment manufacturers to have more choices when producing, and will also deploy more suitable formulas according to the needs of different customers. In addition to the grade of diamond, the particle size of diamond is also very important. Different particle sizes have different expressive power and different prices. In the cutting process of large-grain diamonds, if a suitable bond is used, the cutting efficiency and life will be very excellent, but the price will follow The more expensive it is, and although the price of small particles of diamond is cheaper, the holding power is better, which will make the utilization rate of diamond higher. There are also factors such as the hardness and structure of the diamond that can determine the quality of the segment.

After talking about diamond, let's talk about the bond of the segment. The bond uses metals such as copper, iron, nickel, cobalt, tin, tungsten carbide, zinc, etc., to be blended in different proportions, and its proportion needs to be determined by combining diamond powder particles and uses. The early bonds used a lot of rare metals, but with the improvement of the process, it was found that iron can also be used as the basic material of the bond. Therefore, most of the current segments are made of cheap iron-based materials. Such segments ensure efficiency. At the same time, taking into account the cost performance, it is one of the customers' favorite segment products.

So what is the purpose of diamond segment? The most common use is to use on circular saw blades, such as bridge cutting machine, multi cutting machine, block trimming machine and other stone machinery. In mining, the diamond segment is also required for the quarry machine. The diameter of these circular saw blades is 900-3500mm, mainly for cutting stone. On non-circular saw blades, such as gang saws, diamond segments are also used extensively.

Large saw blades will use diamond segment. For 300-850mm saw blades, segment is also widely used to cut stone, concrete, asphalt and other materials. The applied machinery includes middle cutting machine, infrared bridge cutting machine, hand cutting, hand cutting and other machines.

On 105-300mm saw blades, most of these saw blades are connected to the substrate by laser welding or cold press sintering. However, due to the low cost of such saw blades and the low recycling value of the substrate, almost these saw blades It is a disposable product. But it also needs to use segment.

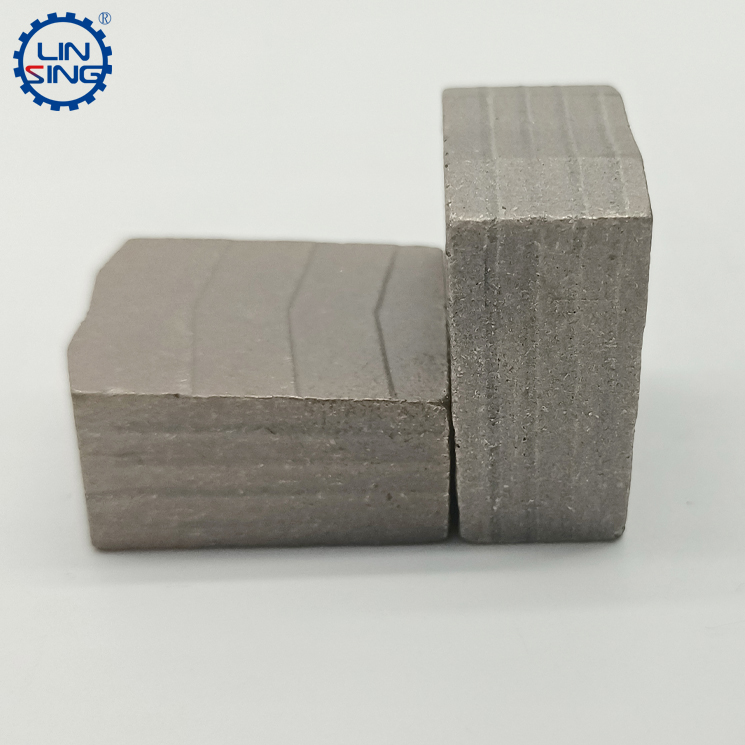

The quality of diamond segment depends on the reasonable ratio of diamond and segment bond. Generally speaking, bond and diamond have the same consumption rate as the best. The best segment performance is that the working surface is convex and the non-working layer is concave. If the diamond segment is smooth, there will be situations such as inability to cut and low efficiency.