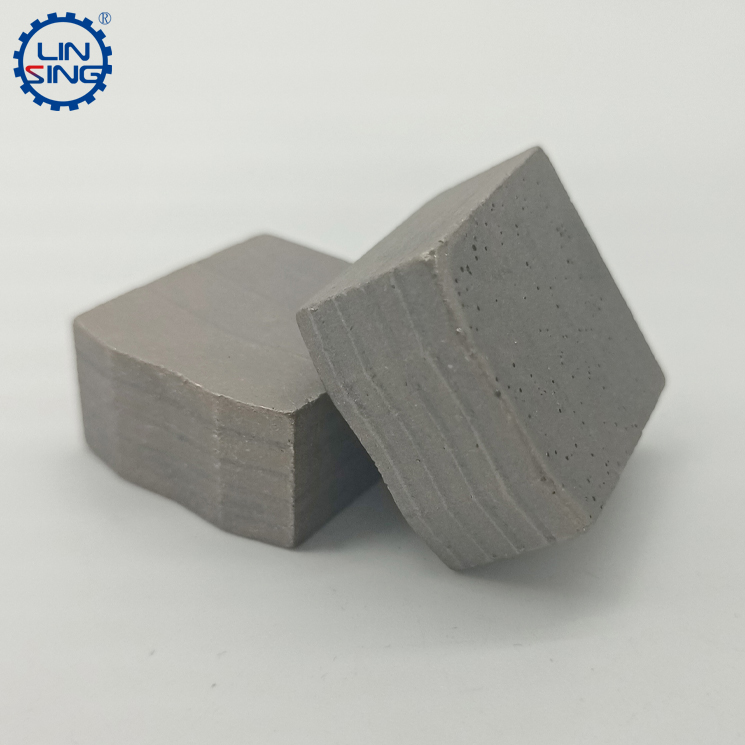

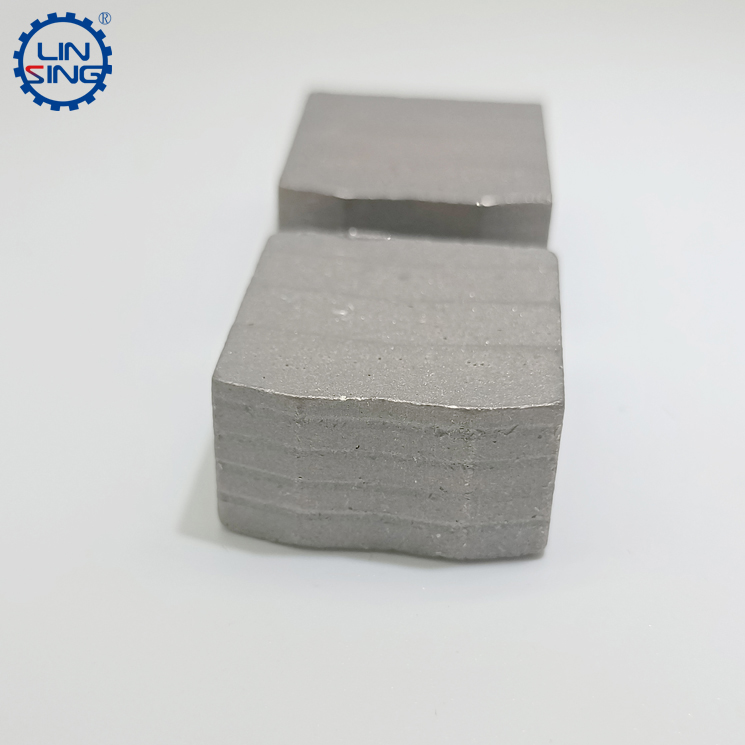

The ultimate purpose of the hot pressing process of diamond segments is to increase the holding force of metal matrix to diamond, according to the high strength of holding force , it can be maximum use of the sharpness and tenacity of diamond to complete the cutting of stone, concrete, steel bar, ceramic tile, asphalt and decorative materials.

The sintering process of diamond is as follows: customized graphite abrasive → applied mould release agent → cold pressed billet (order the working layer and non-working layer as finished segments)→ upper die frame → adiabatic partition on pad → tighten fastening screw → feed into hot press preloading (preloading pressure is 30-40% of hot pressing pressure)→ power heating, heat preservation and pressure keeping (pressure holding pressure is 20-30 MPa)→ pressure relief (down the sintering pressure to 30-40% of sintering pressure) →cooling → unloading.

In the whole process of diamond segments sintering, we need to pay attention to the following points, which are also the most likely problems in the whole process of diamond segments sintering.

1. Customize the appropriate diamond segment mold, if not the customized products, then you need to choose the matching segment size. And for deformation, damage, cracking graphite abrasives to be replaced in time. There must be no different sizes of segment. If the segment with different size , it will not only effect the life and cutting efficiency, but also will destroy the stone surface and make the stone surface scratch, thus affecting the processing of stone.

2.Brush a layer of release agent on all contact surfaces of graphite mould and segments, this step must be done, otherwise it is easy to appear the situation that can not be removed, thus wasting time or even damaging the mold.

3. Install the graphite mould and the segment pressing blank on the special mould pad, the height of the steel mould frame exposed roughly equal to both ends of the graphite pressure head, left the optical temperature measuring hole. Fasten the screws in the length direction of the segments, then fasten the screws in the width direction, and tighten evenly. The product quality tends to be stable during sintering.

4. Check that the straightness and flatness of the graphite electrode plate of the hot pressing machine are good. If not, replace them immediately.

5. Adjust the temperature and pressure automatic control instrument, and set up the holding time and cooling time, conscientiously implement the process standards and segments production standards, no violation of the operation.

6. Cleaning blocks, measuring dimensions and weights. Eliminate bad products in time, so that diamond segments tends to stabilize.

That's all, thanks for reading.

Hot pressing and sintering process of diamond segments

Publish date:2022-07-06 14:11:55 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades