Cutting granite is a very common procedure in the stone processing industry. From the mining of granite, it involves cutting. The granite is mined into blocks, then the blocks are cut into slabs, and finally the slabs are cut to complete the granite. For the processing of countertops, floors, and wall panels, blocks can also be directly cut into special-shaped products such as monuments or tombstones. The cutting process will use diamond segment products to cut these granites. The segment, we call it granite cutting segment.

Granite segment classification

Granite segments can be classified according to their size: segments used for saw blades with a diameter greater than or equal to 900 mm, we call them large segments, and saw blade segments with a diameter greater than 250 mm but less than 900 mm are called mid-diameter saw blade segments, but smaller A saw blade segment with a diameter equal to 230mm is called a small segment, also called a small slice serration.

If the granite segment is classified according to the structure: it can be divided into a sandwich structure and a sandwich structure. The sandwich structure is a three-layer structure with narrow segments on both sides and a wide middle layer; and the sandwich structure is also called a multi-layer segment, and its structure is a working layer plus The multi-layer structure of the non-working layer can be a singular structure such as 3 layers, 5 layers, 7 layers, 9 layers, and 11 layers.

If classified according to the use of circulating water in granite segments: it can be divided into three categories: dry-sliced segments, wet-cut segments, and dry-wet mixed-cut segments. The general size of dry-cut segments and dry-wet mixed-cut segments does not exceed 400mm, and uses Most of the welding methods are laser welding or cold pressing and sintering. High-frequency welding saw blades generally do not support dry cutting or mixed dry and wet cutting.

If it can be classified according to the usage scenarios of granite segments: it can be roughly divided into mining saw segment, single saw segment, combined saw segment, broken segment, horizontal cutting segment, trimming segment and slotting segment.

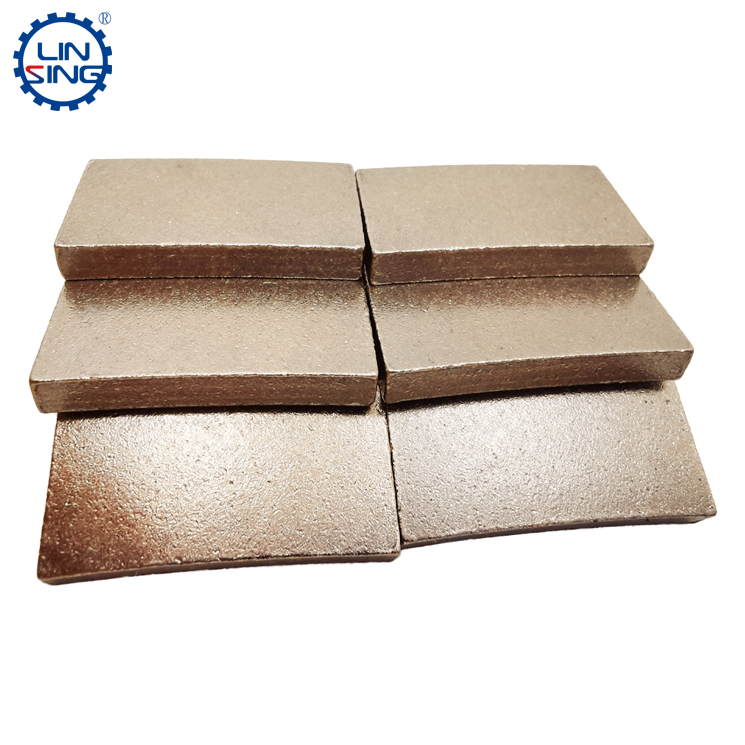

If classified according to the shape of the granite segment: it can be roughly divided into the following categories: M-shaped, flat-shaped, fan-shaped, K-shaped, turbine-shaped, continuous, and so on.

The characteristics of granite segment

The granite segment must have a strong hardness, otherwise, during the cutting of granite, the too soft segment will be directly knocked off or deformed, and the cutting effect will not be achieved. And the carcass needs to have strong wear resistance. Because a large amount of debris will be generated during the cutting of granite, and because the granite itself has strong wear resistance, once the carcass is not wear-resistant, the segment will be quickly consumed. The granite segment needs diamonds as much as possible. Because diamonds and granites are constantly being polished and consumed during the cutting process of granite, the more diamonds, the segment will always be sharp. The advantage of this is that the segment is always sharper. Happening.

The price of granite segment

Since granite segments mostly use iron powder as the basic formula material, the price is less affected by the carcass, but it is more sensitive to the price of diamond. Once the price of diamond rises, the price of segment will also rise. On the contrary, if diamond If the price goes down, the price of the segment will also go down.

Best working environment for granite cutting segment

In the cutting process of granite segment, cooling water is needed. The amount of water should not be too much, because too much water will cause slippage of the tool path and cutting slippage. Of course, the amount of water should not be too little, and too little water will not be able to get up. The effect of cooling the segment affects the stability of the segment. Therefore, the amount of water used is small, but adding coolant to the cooling water can reduce the amount of water, and the segment can be cut quickly and stably while also cooling down well. Therefore, it is particularly important to choose the right amount of water and coolant.

In addition to the water problem, the use of machinery and saw blades is also particularly important. The use of new machines and the use of materials with good rigidity and elasticity for the matrix can further improve the cutting efficiency of the segment and also save production costs. Choosing the granite segment of Linxing diamond tools is your very wise choice.

Granite cutting segment

Publish date:2022-07-08 11:25:59 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Multi-Saw Blade

Diamond Segment For Quarrying&Mining

Diamond Segment For Sandstone Cutting

Related News

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades