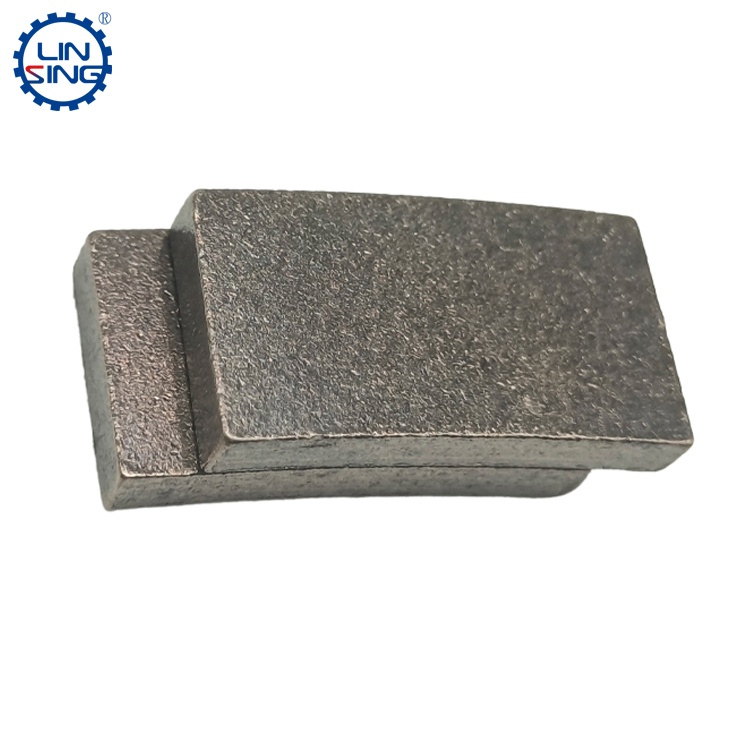

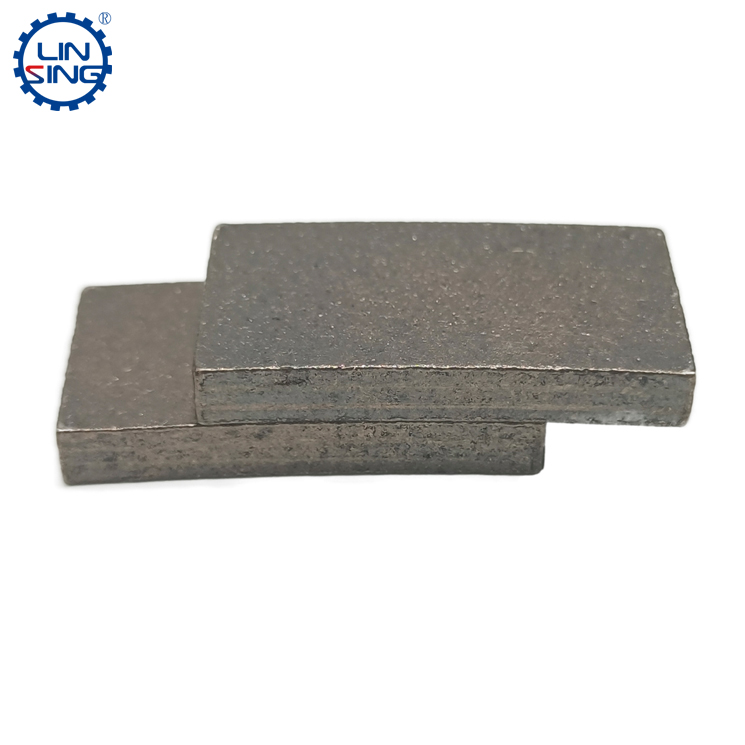

During the cutting process of granite, the segment is welded to the sawing tool, and the cutting machine drives the saw blade to rotate at a high speed, and in the process of continuously advancing and descending, the grinding of the stone is completed, but because each granite stone has Different hardness, abrasiveness, and crystal particle size, so when choosing a segment, you must pay attention to the following points:

The hardness of the diamond in the diamond segment (the grade of diamond): During the process of cutting granite, if the diamond in the segment is not hard enough, the diamond will break and fall off during the cutting process, reducing the cutting efficiency and obviously there is a situation where the cutting cannot be moved, and the problem of tooth loss will often occur. But if the diamond is too hard, in the process of cutting the stone, the diamond consumes the cutting edge and constantly grinds it flat, but it will not break to form a sharper edge, causing the segment to become blunt, and thus unable to cut the stone. Therefore, the granite segment must select diamond powder that is neither high nor low according to the hardness of the stone.

The matrix strength of diamond segment: The diamond segment is composed of a matrix and a diamond. If the matrix is too hard, especially the matrix with greater strength than the diamond, the diamond will be flattened and the saw blade will have to be re-edged. Increasing the workload also reduces the cutting performance; but if the matrix is too soft,matrix consums too fast, and the diamond cannot be fully utilized, because the matrix is worn out, the diamond is forced to fall off in advance, and the diamond powder cannot be fully utilized. From the problem that the product is consumed too quickly and the life is too short. When choosing the matrix of granite segment, it is necessary to formulate a formula that matches the strength of the diamond, which is also the core part of the entire diamond segment design.

The thickness of the diamond in the diamond segment: During the cutting process of granite, if the hardness is high, try to choose diamond powder with smaller particles. Such a segment will be very good because of the diamond powder distribution problem. If you cut soft granite, choose large-grain diamond powder to make the segment more efficient and easier to cut. Of course, theoretically speaking, diamond segment with mixed large and small particles must be the best in terms of compatibility. However, due to the current process barriers, the current particle size is still keep very close.

Diamond concentration in the diamond segment: Generally speaking, the higher the diamond concentration, the longer its life span. However, in terms of sharpness, the concentration continues to increase, the sharpness of the diamond segment first increases and then decreases (it can be understood as a first-up the lower parabola), so the current concentration design of the diamond segment is that the segment design engineer finds the best diamond powder concentration (that is, the vertex of the parabola through the test) through a large number of tests, and achieves the highest efficiency and does not last Too low cutting effect.

There are also some factors related to the matrix, such as the toughness of the matrix, the density of the matrix, the wear resistance of the matrix, etc., which all determine the quality of the granite segment. During the test, these all need to be paid attention to. The toughness of the matirx is reflected in whether the segment is cracked or broken; the density of the matrix is mainly reflected in the stability of cutting, without jitter or offset; as for the wear resistance, it is represented by the speed of the matirx consumption. There is a certain connection with the strength of the matrix.

Several concerns of the granite saw blade segments

Publish date:2022-07-07 10:36:42 Article From:Linsing Diamond Tools Clicks: