There are many elements to consider in the production process of diamond segments. These elements determine product positioning, formula selection, and later sales, which are very important part of the segments ,production process. Especially Jiangxi Linxing Diamond Tools Co., Ltd. has the following five advantages, which are explained in detail below:

Production efficiency: In mass production today, the production of diamond segments has slowly entered the equipment improvement process of automated assembly lines. Automation can maximize production efficiency. In regard of stability, mechanical automation is used instead of labor. It can reduce the uncertainty of the segments in the process of stirring, cold pressing and sintering, and it can also make the segments be produced more quickly. At present, Linxing diamond tools adopt semi-automatic production equipment for the segments production, and the latest automatic machinery is ready to go online.

Process cost: It has always been considered by engineers. In the past, there seemed to be a very big conflict between process and cost. A good process must have a higher cost. But for now, the diamond segments produced by Linxing diamond tools has a highly sophisticated technology, while the cost is reduced because of the effect of the factory scale and the large scale of procurement.

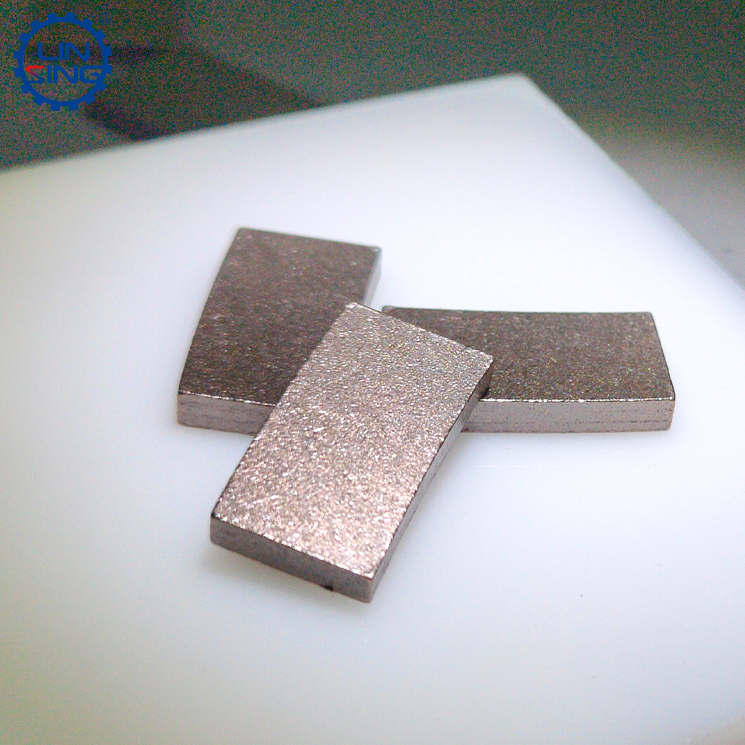

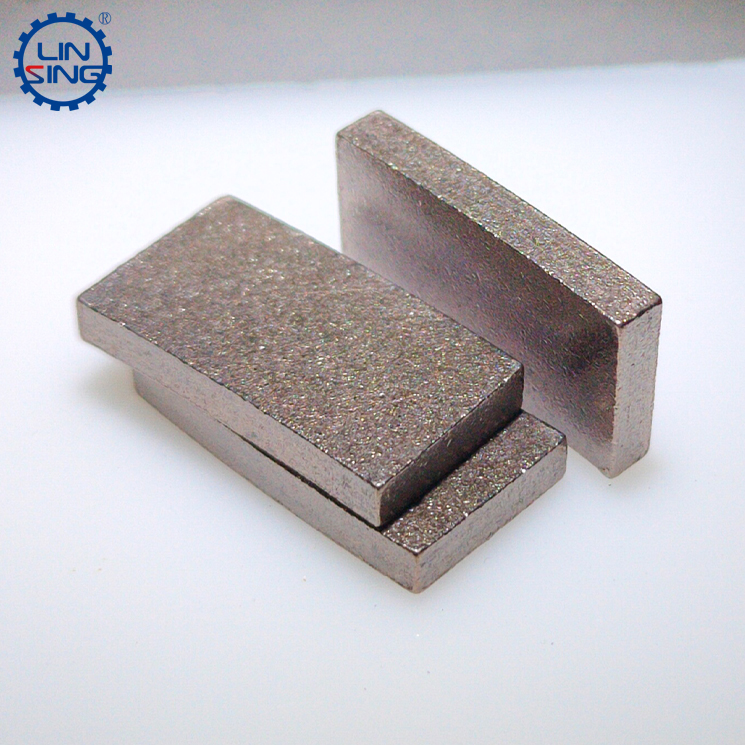

Mould bearing capability: In modern China it is a common to use mould many times. A set of mould is used dozens of times, and even the mould is deformed, which causes large dimensional errors in the appearance of the segments. At present, most of Linxing segments have been used within 10 times to ensure the stability of the product.

Thermal stability control ability: Linxing diamond segments has its own way of adjustment of matrix bond, which can not only hold the diamond firmly and play fully in its energy efficiency, but also can wear simultaneously with the diamond to form a new cutting edge. Especially in the application of large-size segments, such as combined cutting saw large segments, single saw blade segments and quarry segments. Linxing Diamond's matrix can even hold high-grade hardness diamonds well, increasing sawing force. The main reason is that in the sintering process, the matrix is good, which leads to the increase of the chemical bonding force.

Iron-based bonding agent and copper-based bonding agent are used well. Normal manufacturers use high-cobalt, tungsten and other metal bonding, which are very expensive. For cost considerations, Linxing diamond tools use copper-based bond as cutting matrix for soft stone,use the iron-based bond as cutting matrix of hard stone, which greatly reduces the cost. and because the company's matrix binder has a special formula, compared with the expensive cobalt-based matrix, the performance is not much reduced. This is the core competitiveness of Linxing Diamond.