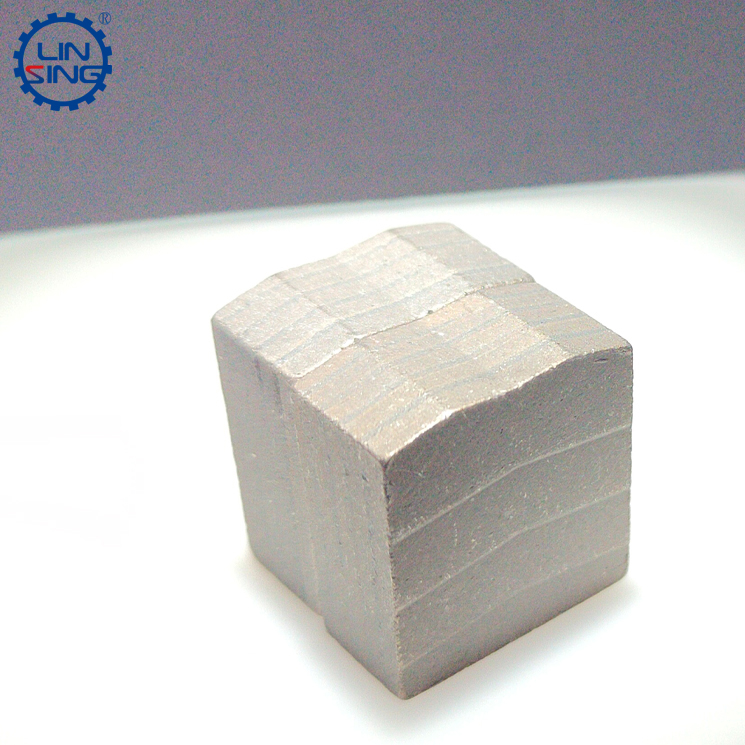

Diamond saw blade segment is made of diamond, metal binder through high temperature and high pressure sintering processing of special powder metallurgical products, of which, diamond part is the main cutting part, through the exposed diamond to complete the cutting of stone, and metal binding agent is fixed diamond, not too wear-resistant, but also not wear-resistant, and diamond wear degree matching for the best, so, good metal binder on the performance of the diamond segment will be very large, and the combination of good or not directly determines the life of the segment and cutting efficiency. So, what design principles do metal binder need to follow in the production process?

1: The holding force of diamond needs to be care. Diamond is a helium structure; this irregular shape needs to match the metal to increase the holding force. The increase of holding force is divided into the increase of physical holding force and chemical holding force. Physical holding force is through the elements inside the metal binder itself have close mechanical holding force. Such as Cr, Mn, W or WC and other elements, and diamond matching, with a strong mechanical holding force, but the mechanical holding force is relatively weak, so also need chemical holding force, through high temperature and heat to let the diamond part of carbonization, and crystal melting, This creates a better chemical hold with diamonds. Therefore, in the design process of the segment, the physical and chemical properties of various metal elements should be considered clearly, because the amount of holding force directly determines the efficiency and life of the segment's later cutting.

2: Synchronous abrasion coordination, diamond in the process of cutting stone will inevitably have part of abrasion, and metal binder in the rapid touch with the stone surface, there will also be normal abrasion, but the loss speed of the two should be consistent. Diamond abrasion too fast, then the binder because it does not have the ability to cut stone, there will be cut, grinding, and even damage to the substrate and machinery. If the binder consumption is too fast, then the diamond will fall off, accelerate consumption, shorten the processing life.

3: Reasonable cost, if the metal binder contains a large number of expensive elements, then the price of the whole segment binder will rise, that lead to the price of the whole segment will rise as well. However, not expensive elements of its binder will be good quality, which still has to take into account the overall adaptation effect of the entire binder. Even good binder, such as Ti, Ca and other elements may also erode diamond, prone to large carbide, resulting in cracks or gaps, weakening cutting performance.Out of the above, the metal binder should also take into account the sintering temperature, pressure, diamond strength, concentration, hardness and other factors, and even take into account the sintering machinery, production process, the quality of operators and so on.

Guidelines for the design of metal binds in diamond segments

Publish date:2022-07-06 10:01:39 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades