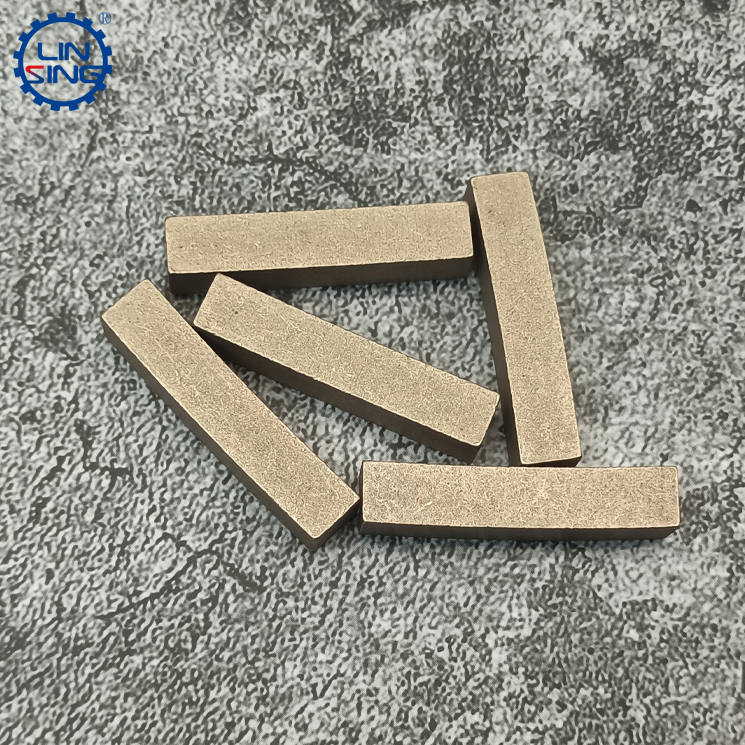

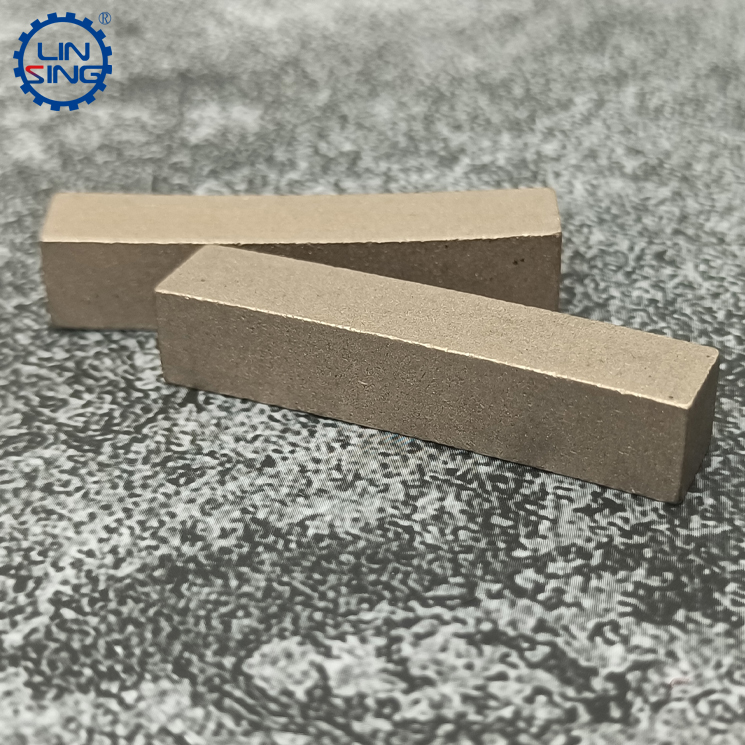

Diamond in the production process, high temperature sintering process, oxygen in graphite abrasives, high temperature and metal react violently, especially on the surface of the head, forming a thin layer of oxidation, this layer of oxidation to protect the head in the transport process of further oxidation, but in the application process, the oxide layer of this film will seriously affect the strength of welding, so before welding, it is necessary to remove this layer of oxidation. This is an important reason why diamond segments need to be grided.

In addition, the jagged part of the circular saw blade has a partial grinding, and the flat part of the diamond segment forms a very distinct welding gap. If forced welding up, too large weld will cause the knife head to fall easily. There will also be a diamond segment high and low not Flat, in the stone cutting process, protruding part of the diamond segment has been cutting, and the concave segment has not worked, such a situation will reduce the life of the segment. The appearance of partial grinding, teething and so on, and grinding is to solve such a problem. The arc of the welding surface of the head is processed into a surface consistent with the arc of the base welding surface, which becomes a necessary process for welding the diamond segment on the circular saw blade.

Common grinding equipment has grinding wheel machine, sand belt grinding machine and special arc grinding machine three kinds of machinery. Below we introduce the characteristics and applications of these arc grinding machine.

Grinding wheel arc machine: grinding wheel arc machine is actually a piece of grinding wheel on top of the circular saw, when the grinding wheel in the process of high-speed rotation, put the welding surface of the segment on, thereby removing the oxidation layer of the diamond segment, but for the high arc requirements of the blade segment, this simple grinding machine obviously doesn’t meet the processing requirements.

Sand belt arc machine: This kind of machine is processed with sand belt, characterized by sharp sand belt, high grinding efficiency, grinding out the arc is more correct, will not be due to the diameter changes and arc deviation. However, the sand belt life is short, need to be replaced frequently, processing costs are higher.

Special arc grinder: This is also the grinding wheel to diamond segment grinding arc. This machine can be very convenient to load and unload the grinding wheel blades, by replacing different grinding wheel blades to process diamond segments. This kind of machine is the most commonly used arc grinder, in terms of cost, but also very advantageous.

Diamond segment in the process of grinding processing, must follow the three-point processing requirements.

First: Because of the segment produces a lot of heat during grinding, it is necessary to wrap the insisting cotton strip around the fingers, and to wear protective gloves.

Second: the arc of the grinding arc should be correct, the arc of the general saw blade and the arc of the grinding wheel is similar, the better the grinding effect.

Third: grinding arc to be uniform, the head welding part must all be ground to, do not appear oxidation layer is not removed.

Diamond segment's grinding process and the selection of machinery

Publish date:2022-07-06 16:59:54 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

- Top 10 Mistakes in the Diamond Segments Selection Process

- Why The Diamond Segments Have Been Processed Into Vavious Shape?

- What should do if the segment is moved grinding during the cutting process?

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades