In the diamond segment production process, heating and pressurization is the core processing step, and also the most important step in segment molding. This step also directly affects the life of the segment finished product and processing efficiency, but many friends do not understand this process. For the detailed process, this article introduces sintering and hot sintering, so that everyone has a better understanding and understanding of the formation of segments.

Sintering diamond segment, people often use this process to directly name the products processed by this process, but in actual applications, the segment does not use such a single processing method in the molding process, but a combination of multiple processing, such as hot sintering, cold pressing sintering and so on.

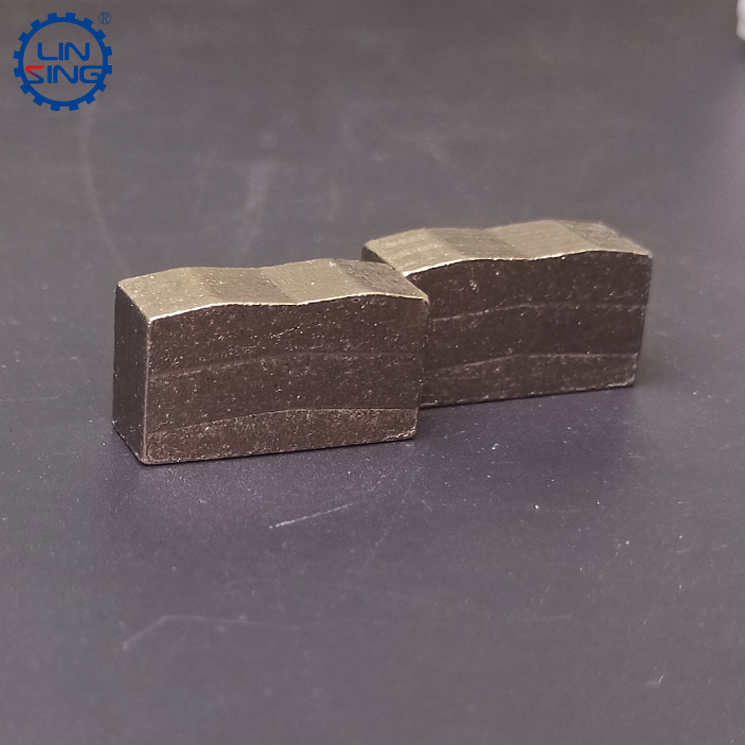

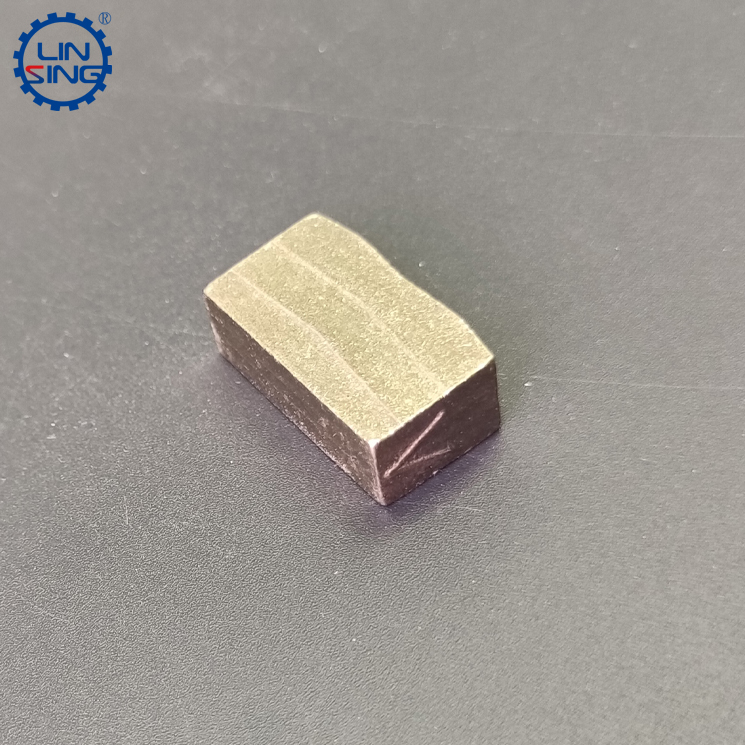

Let us first understand sintering. Sintering is a process of compacting the stirred powder and heating it at the appropriate temperature and air pressure. During the sintering process, the metal powder of the metal bond (also called carcass bond) passes through the process of dissolving, so that the particles are bonded, "burning" is the increase in temperature, and "knot" is the appearance. By heating, the metal material is formed into agglomerates, so the diamond segment is also called diamond agglomeration. From the perspective of the entire process, sintering can be simply regarded as a heat treatment process, and this process is not unconditionally increasing the temperature all the time, but according to the composition of the metal in the bonding agent, the temperature is adjusted to the melting point of these metals, and Maintain this melting point temperature, and after the metal is fused and formed, the entire segment is solidified by cooling. In this process of heating and heat preservation, various physical and chemical changes occur in the segment. The physical changes are mainly reflected in the polymerization after the metal is dissolved, the increase in stress and density, etc., and the chemical manifestation is the carbonization of diamond. Metal bonding agent crystallization and so on. The process of sintering changes the mechanical properties of the segment, including holding power and so on.

However, although separate sintering can make the segment compact, the strength is not high. The earliest segment only uses the sintering process, which requires a long time for sintering and insufficient density, resulting in high segment cost and low cutting efficiency. With the development of diamond segment technology, people found that during the process of heating sintering, if pressure is given, then sintering can be performed in a short time. This process is called hot pressing sintering, also known as pressurized sintering, as the name implies, in the segment Simultaneously pressurize during the sintering process to form a density that cannot be achieved by a single sintering. From the perspective of the final product, hot pressing sintering is an enhanced sintering method, which can greatly shorten the sintering time, and can process a diamond segment with higher density, better life, and higher holding power. There are three main methods of hot-pressing heating: resistance direct heating, indirect resistance heating and induction heating. The production of diamond segment mostly uses resistance direct heating.

At present, most of the separate hot process is used for small slices, which are completed by cold pressing sintering process, while the hot sintering diamond segment is suitable for large saw blades and medium diameter saw blades, which can better save stone processing costs.

Definition of pressurized sintering of diamond segment

Publish date:2022-07-06 16:52:05 Article From:Linsing Diamond Tools Clicks: