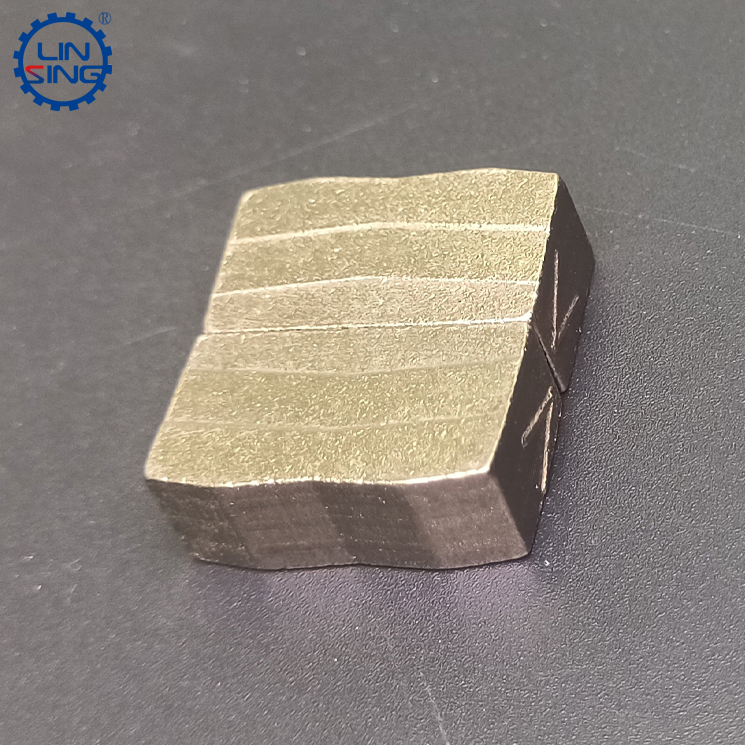

There are several types of conditions in which diamond segments are prone to quality problems:

1: There is a problem with the size specification of the segment. Although the diamond segment is a fixed mold sintered metal alloy and diamond mixture, through cold pressure and hot pressure sintering to complete the final finished product, the material is relatively fixed, but due to the segment processing process. Sintering pressure is not enough, sintering temperature is not enough, or the temperature and pressure insulation during the sintering process is not too high. These reason all will lead to the segment force is not balance, so naturally there will be differences in the size of the segment, the pressure will be too high.

Therefore, in the production process, stability of the same pressure and temperature is very necessary, of course, not only in the pre-loading process, but also to the segment cold press weighing; Diamond segment size does not meet the requirements, density is not enough, hardness does not meet the requirements, the transition layer has debris, segment strength is not enough.

2. If the density is not enough; the segment will soft. In the process of cutting stone, there will be the problem of segment fracture, which is divided into local fracture and overall fracture, no matter which kind of fault, such a segment is not re-used. Of course, the segment break is the limit situation, the density is not enough to cut the segment in the stone, due to their own Moshi hardness is not enough, there segments will consumption too fast. In general, the density of the segment must be guaranteed.

Such a situation is generally because of sintering temperature, insulation time, pressure is not enough, binder material selection error, segment’s diamond content is too high and so on, such a situation is very common, the old formula will also appear such a situation, the general reason is caused by improper operation of workers, and if it is a new formula, most of the reasons are due to the designer's lack of grasp of the formula caused by the designer needs to better conditioning the segment formula, combined with temperature and pressure, Give a more reasonable sintering temperature and pressure.

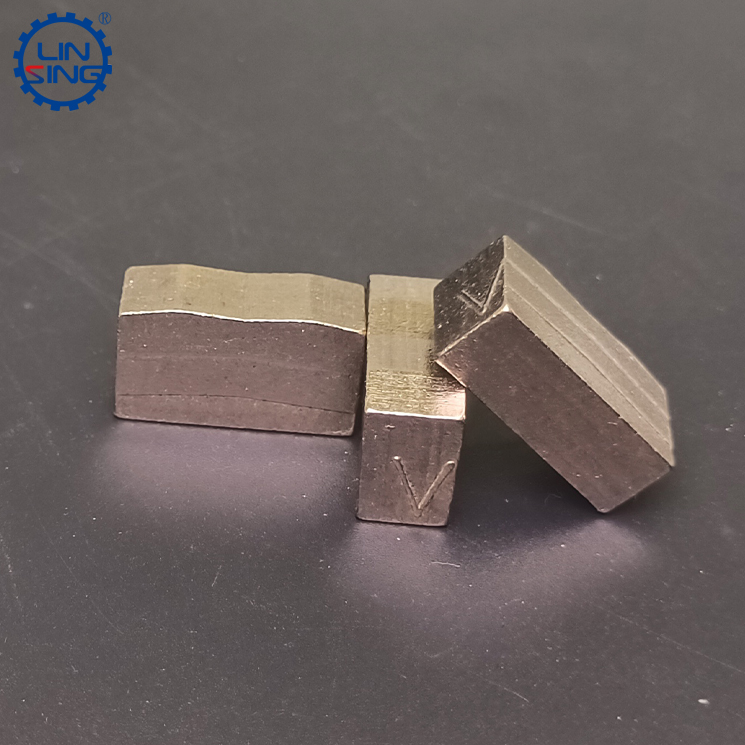

Why the segment does not cut the stone. The main reason is the diamond segment does not move the stone and the strength is not enough.

1: The diamond powder quantity is not enough or the quality of the diamond selected is poor.

2: the inside of the segment mixing, loading mixed with impurities, such as graphite particles, dust, etc., especially in the mixing process, stirring unevenly will also lead to this situation;

3: Diamond excessive carbonization, the temperature is too high, resulting in diamond carbonization is serious, in the cutting process, diamond particles can easily fall off.

4: The segment formulation design is unreasonable, or the sintering process is unreasonable, resulting in low working layer and transition layer strength (or work layer and non-working layer combination is not close), this situation is often in the new formulation.

5: The segment binder is too soft or too hard, resulting in diamond consumption and metal binder consumption is disproportionate, resulting in diamond fetal binder cannot hold diamond powder.

4: The segment falling off. There are many reasons for the segment to fall off, such as too many impurities, too high or too low temperature, insulation time is too short, formula than suitable, welding layer unreasonable, different working layer and non-working formula lead to different coefficients of thermal expansion of the two, when the segment cools, the working layer and non-working connection places appear shrink stress, eventually leading to the knife strength reduction, eventually lead to the segment off and so on. These are the causes of diamond segment shedding or saw blade tooth loss.

To solve this problem, we must ensure that the powder is fully stirred at first and free of impurities, and then match reasonable pressure, temperature, and insulation time, and try to ensure that the thermal expansion coefficient of the working layer and non-working layer is close.

Diamond segment in the working process, there will be other problems, such as excessive consumption, such as stop moving and partial grinding and other issues, many problems are not only the problem of the segments, but may be caused by machinery, stone types and other factors, the following article we will be detailed introduction.

Common problems with diamond segments

Publish date:2022-07-06 16:08:03 Article From:Linsing Diamond Tools Clicks: